News

-

![High-Precision Aluminium Cold Rolling Mill Solutions [Brand] High-Precision Aluminium Cold Rolling Mill Solutions [Brand]](https://www.bjywlx.com/images/7_womens-day1741403223.webp) Boost efficiency with our advanced aluminium cold rolling mills. Ideal for automotive, aerospace, and packaging industries. Durable, energy-saving designs with custom configurations. Contact us for tailored aluminum processing solutions today!Read more

Boost efficiency with our advanced aluminium cold rolling mills. Ideal for automotive, aerospace, and packaging industries. Durable, energy-saving designs with custom configurations. Contact us for tailored aluminum processing solutions today!Read more -

Optimize cold rolling processes with our Streifenspannungsregler – ensures uniform strip tension, minimizes material defects, and boosts production efficiency. Ideal for steel mills and metalworking industries. Request a technical consultation now to upgrade your rolling mill performance.Read more

Optimize cold rolling processes with our Streifenspannungsregler – ensures uniform strip tension, minimizes material defects, and boosts production efficiency. Ideal for steel mills and metalworking industries. Request a technical consultation now to upgrade your rolling mill performance.Read more -

Enhance pipe durability with our advanced roll coating process. Ideal for industrial applications, our solution offers corrosion resistance and cost efficiency. Contact us for a customized quote!Read more

Enhance pipe durability with our advanced roll coating process. Ideal for industrial applications, our solution offers corrosion resistance and cost efficiency. Contact us for a customized quote!Read more -

Maximize efficiency with our automated packaging machines. Perfect for spices, food, and industrial goods, featuring rapid strapping and precise sealing. Streamline operations and cut costs. Explore custom solutions now! Contact us for a free consultation.Read more

Maximize efficiency with our automated packaging machines. Perfect for spices, food, and industrial goods, featuring rapid strapping and precise sealing. Streamline operations and cut costs. Explore custom solutions now! Contact us for a free consultation.Read more -

Maximize equipment efficiency with durable hydraulic tension control systems and genuine repuestos. Ideal for industrial machinery, manufacturing, and maintenance. Ensure precise tension regulation and extended system lifespan. Contact experts today for customized solutions!Read more

Maximize equipment efficiency with durable hydraulic tension control systems and genuine repuestos. Ideal for industrial machinery, manufacturing, and maintenance. Ensure precise tension regulation and extended system lifespan. Contact experts today for customized solutions!Read more -

Get durable hydraulic cylinder components from leading suppliers. Premium-quality replacement parts for construction, agriculture & industrial machinery. Fast global shipping & OEM solutions available. Request quotes or order now!|Read more

Get durable hydraulic cylinder components from leading suppliers. Premium-quality replacement parts for construction, agriculture & industrial machinery. Fast global shipping & OEM solutions available. Request quotes or order now!|Read more -

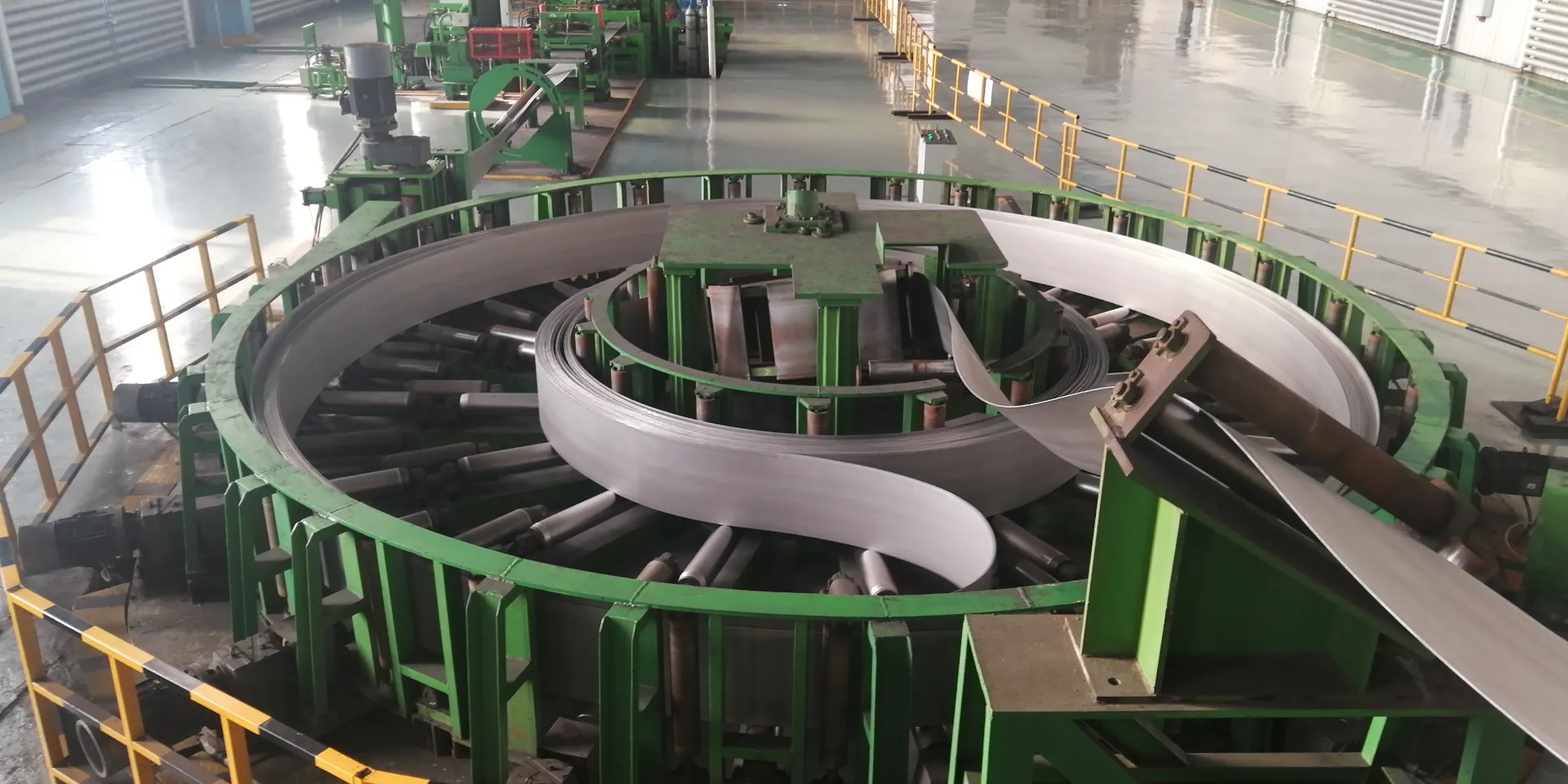

The reversible cold rolling mill is a critical piece of equipment in modern steel manufacturing, enabling precise thickness reduction and mechanical property enhancement through controlled deformation.Read more

The reversible cold rolling mill is a critical piece of equipment in modern steel manufacturing, enabling precise thickness reduction and mechanical property enhancement through controlled deformation.Read more -

Contemporary skin pass mill operations require sophisticated control systems to maintain elongation rates within tight tolerances, often as narrow as ±0.1%.Read more

Contemporary skin pass mill operations require sophisticated control systems to maintain elongation rates within tight tolerances, often as narrow as ±0.1%.Read more -

The fundamental working principle of a reversible cold rolling mill involves passing the strip back and forth between the work rolls, with each pass applying controlled reduction.Read more

The fundamental working principle of a reversible cold rolling mill involves passing the strip back and forth between the work rolls, with each pass applying controlled reduction.Read more -

The skin pass mill serves as the final arbiter of surface quality in modern steel production, where microscopic texture characteristics determine macroscopic paint performance.Read more

The skin pass mill serves as the final arbiter of surface quality in modern steel production, where microscopic texture characteristics determine macroscopic paint performance.Read more -

The skin pass mill represents the final and most critical stage in producing high-quality flat-rolled steel products, where precise control of elongation rate determines the material's final mechanical properties and surface characteristics.Read more

The skin pass mill represents the final and most critical stage in producing high-quality flat-rolled steel products, where precise control of elongation rate determines the material's final mechanical properties and surface characteristics.Read more -

The reversible cold rolling mill has become an indispensable component in modern stainless steel manufacturing, offering unique advantages in processing high-grade alloys.Read more

The reversible cold rolling mill has become an indispensable component in modern stainless steel manufacturing, offering unique advantages in processing high-grade alloys.Read more