Automated Packaging Machines High-Speed & Precision Solutions

- Market Growth and Demand for Automated Packaging Solutions

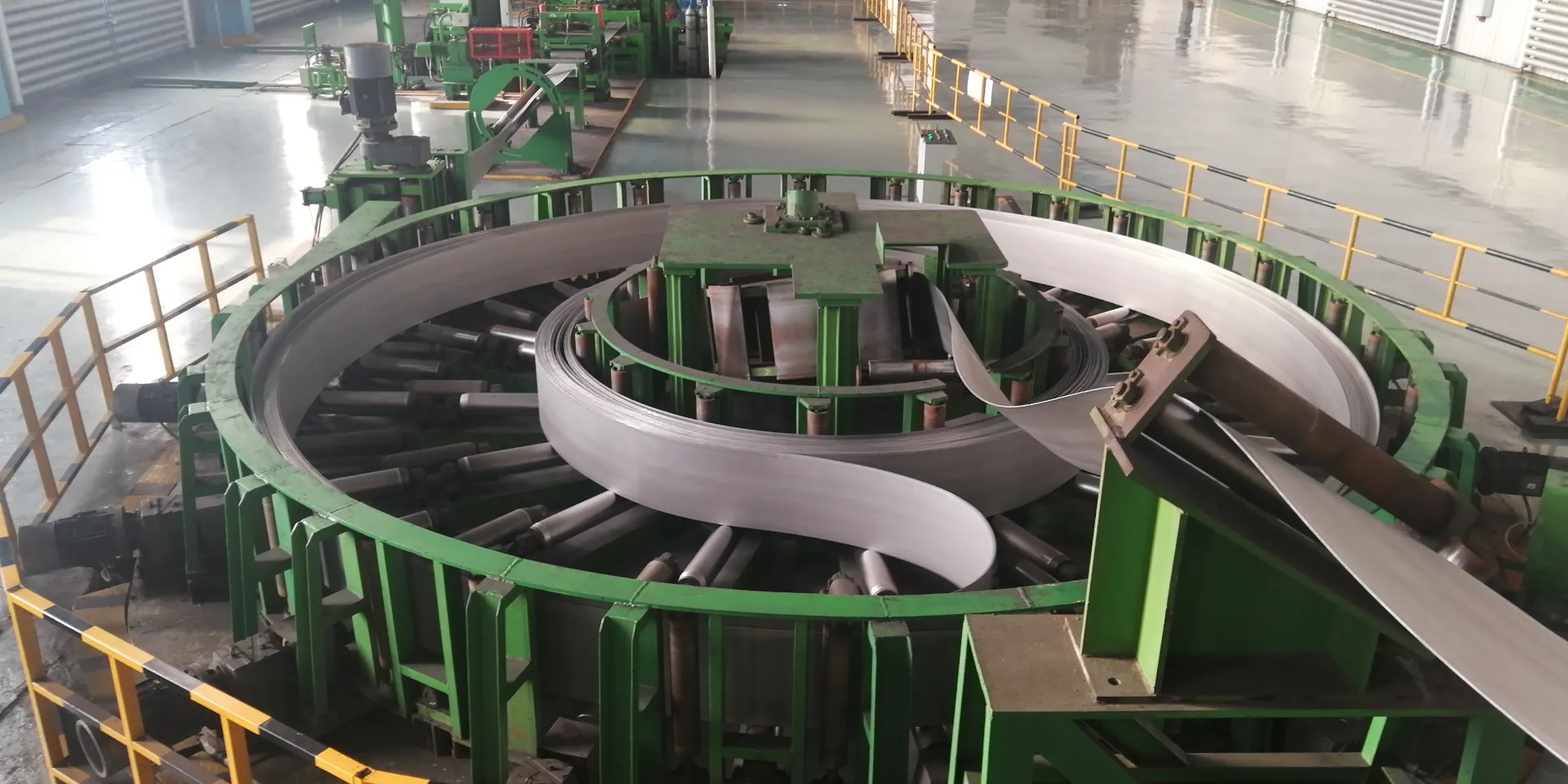

- Technical Superiority in Modern Packaging Machinery

- Performance Comparison of Leading Packaging Machine Manufacturers

- Customizable Solutions for Diverse Industry Needs

- Case Study: Enhancing Efficiency in Food & Logistics

- Future Trends in Automated Packaging Technology

- Why Choose máquina de embalaje de condimentos for Precision Packaging?

(máquina de embalaje automática)

Market Growth and Demand for máquina de embalaje automática

The global automated packaging machinery market is projected to reach $89.7 billion by 2030, growing at a CAGR of 7.2%. Industries increasingly adopt máquina flejadora de embalaje to reduce labor costs by 40-60% while achieving 99.2% packaging consistency. Food manufacturing sectors report 31% faster production cycles after implementing pallet strapping automation.

Technical Superiority in Modern Packaging Machinery

Advanced models now integrate:

- AI-powered tension control (±0.05N accuracy)

- Multi-material compatibility (PET, steel, composite straps)

- 1200+ cycles/hour operation capacity

These innovations enable máquina de embalaje automática systems to handle temperature-sensitive products like pharmaceuticals within ±1°C stability ranges.

Performance Comparison of Leading Manufacturers

| Brand | Speed (cycles/hr) | Material Compatibility | Energy Use (kWh) | Price Range (USD) |

|---|---|---|---|---|

| TechPack Pro X9 | 1,350 | 8 materials | 4.2 | 85,000-110,000 |

| Straub S-2000 | 980 | 5 materials | 6.8 | 62,000-78,000 |

| AutoBind Master | 1,620 | 12 materials | 3.9 | 128,000-145,000 |

Customizable Solutions for Diverse Industry Needs

Modular designs allow configuration for:

- Pharma-grade stainless steel housings

- High-speed rotary arm systems (up to 2.4m/sec)

- Multi-lingual HMI interfaces

A beverage producer achieved 22% higher throughput after implementing dual-channel máquina de embalaje automática with integrated weight verification.

Case Study: Enhancing Efficiency in Food & Logistics

Major spice manufacturer reduced packaging errors by 78% using máquina de embalaje de condimentos with:

- Precision portion control (±0.3g accuracy)

- Nitrogen flushing capability

- Automatic batch coding

Logistics partner XYZ reported 41% fewer damaged pallets after adopting automated corner board applicators.

Future Trends in Automated Packaging Technology

Emerging technologies include:

- Self-learning predictive maintenance systems

- Blockchain-enabled package tracking

- Carbon-neutral energy configurations

Industry surveys indicate 68% of manufacturers plan to upgrade to IoT-connected máquina flejadora de embalaje by 2026.

Why Choose máquina de embalaje de condimentos for Precision Packaging?

Specialized models for spice packaging deliver:

- 0.05mm thickness detection for barrier films

- Moisture control below 3% RH

- 120 bags/minute production rate

Operational data shows 92% client retention rate among users of advanced seasoning packaging systems.

(máquina de embalaje automática)

FAQS on máquina de embalaje automática

Q: What are the key benefits of using an automatic packaging machine?

A: Automatic packaging machines improve efficiency, reduce labor costs, and ensure consistent packaging quality. They are ideal for high-volume production lines and minimize human error.

Q: How does a strapping machine differ from other packaging machines?

A: A strapping machine secures packages with straps or bands for safe transport, while general packaging machines focus on sealing or wrapping products. It’s essential for stabilizing heavy or bulky loads.

Q: What should I consider when choosing a seasoning packaging machine?

A: Prioritize machines with corrosion-resistant materials, precise dosing capabilities, and compatibility with various seasoning textures. Hygiene and easy cleaning are also critical for food-grade applications.

Q: Can automatic packaging machines handle different packaging materials?

A: Yes, most modern machines support materials like plastic, foil, or biodegradable films. Ensure the machine’s settings are adjustable to accommodate material thickness and type.

Q: What maintenance is required for a flejadora de embalaje (strapping machine)?

A: Regularly clean debris, check strap tension, and lubricate moving parts. Scheduled inspections prevent wear and ensure consistent performance.

-

YWLX’s 1450mm Six-Hi Reversing Mill Goes Live in BangladeshNewsOct.28,2025

-

Adjusting Roll Gap in 6Hi Reversing Cold Rolling Mill for Thin StripNewsNov.13,2025

-

Quality Control Standards for Automatic Gauge Control in Strip RollingNewsNov.13,2025

-

Effect of Skin Pass Rolling on Metal DuctilityNewsNov.13,2025

-

Key Components of a Modern TempermillNewsNov.13,2025

-

Common Wear Patterns of Work Roll in Tandem Cold Mill OperationsNewsNov.13,2025

-

Revolutionary Skin Pass Rolling Technology for Enhanced Steel QualityNewsNov.04,2025