Application and Challenges of Reversible Cold Rolling Mill in Stainless Steel Rolling

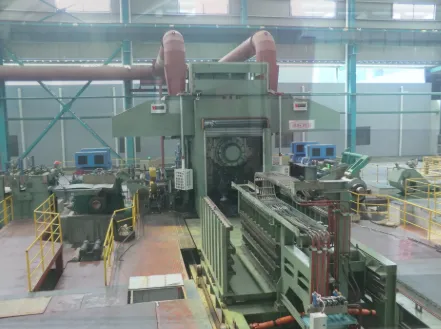

The reversible cold rolling mill has become an indispensable component in modern stainless steel manufacturing, offering unique advantages in processing high-grade alloys. Unlike traditional tandem mills, a reversing cold rolling mill enables multiple passes of the same strip through a single stand, making it particularly suitable for small-to-medium batch production of specialty steels. This flexibility is crucial in stainless steel rolling, where precise control over mechanical properties and surface finish is paramount.

Cold reversing mills have evolved significantly since their introduction, with modern versions incorporating advanced automation, precision gauge control, and sophisticated roll cooling systems. The ability of a reversing rolling mill to handle various stainless steel grades - from austenitic 304 to duplex 2205 - while maintaining tight tolerances has made it the equipment of choice for many specialty steel producers. These mills typically operate at speeds up to 1200 m/min with thickness reductions ranging from 60% to 90% in multiple passes.

Key Applications of Reversing Cold Rolling Mills in Stainless Steel Processing

The reversing cold rolling mill finds its most significant applications in producing high-quality stainless steel strips with precise thickness control and superior surface finish. One primary application is in the production of precision strips for critical industries such as aerospace, medical equipment, and electronics. The cold reversing mill excels at achieving the ultra-thin gauges (down to 0.05mm) required for these applications while maintaining the stringent flatness and surface quality standards demanded by end-users.

Another crucial application lies in the processing of specialty stainless steel grades. The reversing rolling mill configuration allows for optimal processing of challenging materials like high-strength duplex steels or superaustenitic grades containing high molybdenum content. These materials often require specific rolling schedules with intermediate annealing, making the flexibility of a reversible cold rolling mill particularly advantageous. The mill can accommodate varying reduction rates between passes and adjust rolling parameters dynamically to suit the metallurgical requirements of each specific alloy.

The reversing cold rolling mill also plays a vital role in producing stainless steel with special surface finishes. From standard 2B finishes to specialized polished or textured surfaces, the mill's ability to control roll surface conditions and apply precise rolling forces enables manufacturers to create differentiated products. This capability is especially valuable in architectural applications where surface appearance is as important as mechanical properties.

Operational Challenges in Reversing Cold Rolling of Stainless Steel

Despite its numerous advantages, operating a reversing cold rolling mill for stainless steel production presents several technical challenges. One primary difficulty lies in maintaining consistent surface quality across multiple passes. Stainless steel's tendency to work harden and its sensitivity to surface defects require meticulous control of roll surface conditions and lubrication in a cold reversing mill. Any imperfections in the work rolls or contamination in the rolling oil can lead to surface defects that are particularly unacceptable in decorative or high-precision applications.

Another significant challenge is managing the thermal expansion of rolls during prolonged rolling campaigns. The reversing rolling mill configuration, with its continuous back-and-forth operation, creates complex thermal profiles in the work rolls. This thermal behavior can lead to variations in strip profile and requires sophisticated roll cooling systems and thermal crown control mechanisms to maintain product consistency. The problem becomes more pronounced when rolling high-strength stainless grades that require greater rolling forces.

The reversible cold rolling mill also faces challenges related to strip threading and tail-out operations. Stainless steel's combination of high strength and low elongation compared to carbon steel makes these transitional operations more prone to strip breaks or edge damage. Modern mills address this through advanced automation systems that carefully control tension and speed during threading sequences, but it remains an area requiring constant attention from operators.

Technological Innovations in Modern Reversing Cold Rolling Mills

Recent technological advancements have significantly enhanced the capabilities of reversing cold rolling mills for stainless steel applications. One major innovation is the development of hybrid drive systems that combine conventional AC motors with hydraulic screw-down mechanisms. These systems in modern cold reversing mills provide faster response times for gauge adjustments and improved energy efficiency during direction changes, crucial for maintaining productivity in stainless steel rolling.

Another important advancement is the integration of machine learning algorithms into mill control systems. Contemporary reversing rolling mills now utilize predictive models that optimize rolling schedules based on real-time measurements of strip properties and roll conditions. These systems can automatically adjust parameters like rolling force, speed, and lubrication between passes to achieve the desired mechanical properties while minimizing defects.

Rolling oil technology has also seen significant improvements specifically for reversible cold rolling mill applications in stainless steel. New synthetic oils with enhanced lubrication properties and reduced staining characteristics have been developed to meet the stringent surface quality requirements of stainless products. These advanced lubricants also contribute to longer work roll life and reduced energy consumption during rolling.

Future Trends in Cold Reversing Mill Technology for Stainless Steel

The future development of reversing cold rolling mills for stainless steel applications is moving toward even greater automation and flexibility. One emerging trend is the development of "smart" cold reversing mills equipped with comprehensive IoT sensors and connected to centralized data analytics platforms. These systems will enable predictive maintenance and self-optimizing rolling schedules based on real-time performance data and historical trends.

Another important direction is the integration of reversing rolling mills with upstream and downstream processes to create more continuous production flows. While the inherent nature of a reversible cold rolling mill involves batch processing, new coil handling and storage technologies are being developed to minimize interruptions between rolling campaigns and improve overall line efficiency.

Sustainability considerations are also driving innovation in reversing cold rolling mill design. New generations of mills are being developed with energy recovery systems that capture and reuse the significant braking energy generated during direction changes. Additionally, dry rolling technologies that eliminate or minimize the use of rolling oils are under development to address environmental concerns while maintaining the surface quality requirements of stainless steel products.

-

YWLX’s 1450mm Six-Hi Reversing Mill Goes Live in BangladeshNewsOct.28,2025

-

Adjusting Roll Gap in 6Hi Reversing Cold Rolling Mill for Thin StripNewsNov.13,2025

-

Quality Control Standards for Automatic Gauge Control in Strip RollingNewsNov.13,2025

-

Effect of Skin Pass Rolling on Metal DuctilityNewsNov.13,2025

-

Key Components of a Modern TempermillNewsNov.13,2025

-

Common Wear Patterns of Work Roll in Tandem Cold Mill OperationsNewsNov.13,2025

-

Revolutionary Skin Pass Rolling Technology for Enhanced Steel QualityNewsNov.04,2025