Precision Texturing in Skin Pass Rolling: Optimizing Surface Characteristics for Superior Paintability

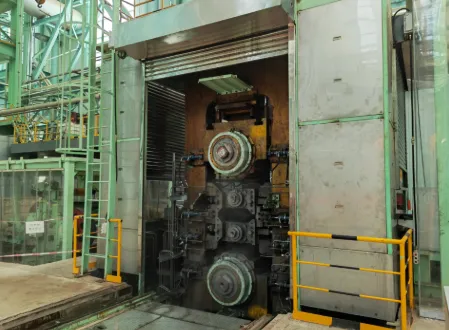

The skin pass mill serves as the final arbiter of surface quality in modern steel production, where microscopic texture characteristics determine macroscopic paint performance. This critical finishing process, technically referred to as skin pass rolling, transforms flat-rolled steel into a substrate ideally prepared for coating applications. Contemporary skin pass mill configurations integrate advanced backup roller systems with precision tension controls to create surfaces that meet exacting automotive and appliance industry standards.

The Science of Surface Texturing in Skin Pass Operations

Skin pass rolling represents a sophisticated interplay between mechanical deformation and surface replication. As steel strip passes through the work rolls, the skin pass process simultaneously strain-hardens the material while transferring the roll's micro-topography to the strip surface. The backup roller assembly maintains perfect roll alignment during this delicate operation, ensuring uniform pressure distribution across the entire strip width. This mechanical precision directly translates to consistent peak counts and roughness parameters that painters require for optimal coating performance.

Backup Roller Innovations Enhancing Skin Pass Consistency

Modern backup roller designs have revolutionized texture control in skin pass mill operations. These critical components now feature:

Segmented temperature control systems preventing thermal crown variations

Active vibration damping technology eliminating surface patterning

Real-time load monitoring for instantaneous mill adjustments

Such advancements in backup roller technology allow contemporary skin pass rolling operations to maintain texture uniformity within ±0.05 µm Ra throughout entire production runs, even when processing high-strength steels that challenge conventional mills.

Automated Texture Control in Skin Pass Rolling Processes

The integration of closed-loop automation has transformed skin pass mill capabilities for paint-grade products. Sophisticated control systems now:

Continuously monitor surface topography using laser scanners

Dynamically adjust rolling force based on real-time texture measurements

Synchronize with downstream automatic packaging machine systems

This automation ensures each coil receives the precise skin pass treatment required for its specific end-use application, whether demanding automotive exterior panels or high-gloss appliance surfaces.

Skin Pass Parameters Directly Impacting Paint Performance

Critical skin pass rolling variables that determine final paintability include:

Reduction percentage (typically 0.5-2.0%) affecting surface strain hardening

Interstand tension influencing texture replication fidelity

Rolling speed impacting thermal effects on surface morphology

Modern skin pass mill operators balance these parameters using advanced process models that predict painted appearance based on rolling conditions, eliminating costly trial-and-error approaches.

Automatic Packaging Machine Integration Preserving Surface Quality

Following precise skin pass rolling, the automatic packaging machine plays a crucial protective role by:

Applying non-contact wrapping systems that preserve delicate textures

Incorporating cleanroom-class environments for premium products

Encoding skin pass mill parameters into traceability systems

This seamless transition from skin pass to packaging ensures the carefully engineered surface characteristics survive transportation and storage until painting occurs.

Future Trends in Skin Pass Technology for Enhanced Paintability

Emerging skin pass mill developments promise further improvements:

Laser-textured work rolls enabling dynamic pattern changes

AI-driven skin pass rolling parameter optimization

Nanoscale surface characterization guiding mill adjustments

These advancements will allow even more precise matching of skin pass textures to specific paint chemistries and application methods.

Skin Pass Rolling as a Critical Paint Preparation Process

The modern skin pass mill has evolved far beyond simple temper rolling, now standing as a precision surface engineering system. Through advanced backup roller designs, sophisticated skin pass rolling controls, and integrated automatic packaging machine solutions, steel producers can consistently deliver surfaces optimized for perfect paint performance. As paint technologies advance, so too will skin pass capabilities, ensuring this critical process continues to meet ever-more demanding surface quality requirements.

-

YWLX’s 1450mm Six-Hi Reversing Mill Goes Live in BangladeshNewsOct.28,2025

-

Adjusting Roll Gap in 6Hi Reversing Cold Rolling Mill for Thin StripNewsNov.13,2025

-

Quality Control Standards for Automatic Gauge Control in Strip RollingNewsNov.13,2025

-

Effect of Skin Pass Rolling on Metal DuctilityNewsNov.13,2025

-

Key Components of a Modern TempermillNewsNov.13,2025

-

Common Wear Patterns of Work Roll in Tandem Cold Mill OperationsNewsNov.13,2025

-

Revolutionary Skin Pass Rolling Technology for Enhanced Steel QualityNewsNov.04,2025