Skin Pass Technology for High-Strength Steel: Key Considerations

The skin pass mill has become an indispensable component in the production of high-quality steel, particularly for high-strength grades requiring precise surface characteristics and mechanical properties. Skin pass rolling, a final light cold rolling process typically applying 0.5-3% reduction, serves multiple critical functions in steel manufacturing. This sophisticated process not only enhances surface finish but also improves mechanical properties and ensures dimensional stability for demanding applications.

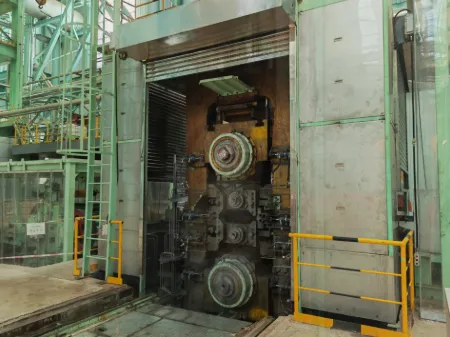

For high-strength steels, the skin pass operation presents unique challenges that require careful consideration of mill design, process parameters, and material behavior. The interaction between the work rolls and backup roller system must be precisely controlled to achieve consistent results without compromising the steel's carefully developed strength characteristics. Modern skin pass mills incorporate advanced automation and control systems to meet these challenges while maintaining high production efficiency.

The Role of Skin Pass in High-Strength Steel Production

Skin pass technology plays a pivotal role in preparing high-strength steel for subsequent forming operations and end-use applications. The process imparts several essential characteristics to the steel strip that cannot be achieved through conventional rolling alone. One of the primary benefits is the elimination of yield point elongation, a phenomenon that can cause uneven deformation during stamping or pressing operations. By carefully controlling the amount of reduction in the skin pass mill, manufacturers can ensure consistent forming behavior across the entire coil.

The process also significantly improves surface texture, which is crucial for automotive and appliance applications where paint adhesion and appearance are critical quality factors. Modern skin pass mills can impart specific surface roughness profiles tailored to customer requirements, ranging from mirror finishes for exposed automotive panels to controlled rough surfaces for improved paint bonding. This surface modification occurs while maintaining the steel's carefully developed mechanical properties, a delicate balance that requires precise control of rolling parameters.

Critical Design Features of Modern Skin Pass Mills

The design of a hot skin pass mill for high-strength steel applications incorporates several specialized features to handle the unique challenges posed by these materials. Mill stiffness becomes particularly important when processing high-strength grades, as the higher rolling pressures require robust construction to maintain precise gauge control. The backup roller system in these mills is typically designed with enhanced rigidity to prevent deflection under load, ensuring consistent pressure across the entire strip width.

Temperature control represents another critical design consideration, particularly for hot skin pass applications where the thermal effects on material properties must be carefully managed. Sophisticated cooling systems maintain optimal roll temperatures to ensure consistent surface finish while preventing thermal crown development that could affect strip flatness.

Skin Pass Mills: Process Optimization for High-Strength Grades

Achieving optimal results in skin pass rolling of high-strength steels requires careful adjustment of numerous process parameters. The amount of elongation applied during processing must be precisely controlled to achieve the desired mechanical properties without overworking the material. Excessive reduction can lead to edge cracking or other surface defects, while insufficient working may fail to eliminate yield point elongation completely.

Roll force control represents another critical parameter that requires continuous adjustment based on material grade, thickness, and incoming properties. Modern skin pass mills employ sophisticated automatic control systems that dynamically adjust rolling parameters based on real-time feedback from multiple sensors along the processing line. These systems can compensate for variations in material hardness across the coil length, ensuring consistent results from lead to tail.

The interaction between tension control and reduction parameters must also be carefully balanced, particularly for thin gauge high-strength materials. Integrated control systems coordinate the operation of the skin pass mill with upstream and downstream equipment, including the automatic packaging machine that handles the finished product. This coordination ensures stable processing conditions throughout the entire production sequence.

Surface Quality Considerations in Skin Pass Operations

The surface finishing capabilities of skin pass technology are particularly important for high-strength steel applications where appearance and coating performance are critical. The process can modify surface topography in several ways, depending on the specific requirements of the end application. Work roll surface preparation techniques have advanced significantly, allowing mills to impart precisely controlled surface textures that optimize subsequent processing steps.

For automotive applications, the skin pass mill must create a surface that promotes excellent paint adhesion while maintaining the desired visual appearance. This often involves creating a specific peak count and roughness profile that facilitates paint wetting and bonding. The backup roller system plays an important role in maintaining the consistency of this surface finish by ensuring uniform pressure distribution across the strip width.

In some applications, the skin pass process is used to remove surface oxides or other contaminants that could affect downstream processing or product performance. The combination of mechanical working and carefully controlled tension helps clean the strip surface while maintaining the integrity of the base material. This cleaning action is particularly important for high-strength steels that may be sensitive to surface defects.

Skin Pass Mills: Integration with Downstream Processing Equipment

The effectiveness of skin pass technology depends heavily on its integration with other mill components and downstream processing equipment. Modern production lines feature seamless coordination between the skin pass mill and subsequent operations such as inspection, coating, and the automatic packaging machine that prepares the final product for shipment.

This integration extends to data collection and analysis systems that track quality parameters throughout the entire production sequence. Information from the skin pass process is combined with data from upstream and downstream operations to provide a complete quality picture for each coil. This comprehensive approach to quality assurance is particularly valuable for high-strength steel products where performance characteristics must be tightly controlled.

The automatic packaging systems that follow the skin pass mill have also evolved to handle the unique requirements of high-strength steel products. These systems must protect the carefully developed surface characteristics while ensuring safe handling and transportation of the often heavier coils associated with high-strength materials. Modern packaging solutions incorporate protective films and edge guards specifically designed for these demanding applications.

-

YWLX’s 1450mm Six-Hi Reversing Mill Goes Live in BangladeshNewsNov.24,2025

-

Adjusting Roll Gap in 6Hi Reversing Cold Rolling Mill for Thin StripNewsNov.13,2025

-

Quality Control Standards for Automatic Gauge Control in Strip RollingNewsNov.13,2025

-

Effect of Skin Pass Rolling on Metal DuctilityNewsNov.13,2025

-

Key Components of a Modern TempermillNewsNov.13,2025

-

Common Wear Patterns of Work Roll in Tandem Cold Mill OperationsNewsNov.13,2025

-

Revolutionary Skin Pass Rolling Technology for Enhanced Steel QualityNewsNov.04,2025