How Skin Pass Technology Prevents Springback And Enhances Dimensional Accuracy

In precision steel production, skin pass rolling represents a sophisticated final processing step that goes far beyond simple surface treatment. This specialized rolling operation, typically applying just 0.5-3% reduction, serves as the crucial bridge between steel mills and end-users by transforming theoretically flat strip into dimensionally stable, fabrication-ready material. The skin pass mill, whether processing material hot or cold, addresses two of the most persistent challenges in sheet metal production: springback and dimensional inconsistency.

The science behind skin pass technology reveals why it has become indispensable for premium steel products. When conventional rolling processes impart significant plastic deformation, they create internal stresses that manifest as springback - the steel's tendency to return partially to its original shape after forming. This effect becomes particularly problematic with advanced high-strength steels where higher yield strengths amplify springback forces. A well-tuned skin pass rolling operation fundamentally alters the material's response characteristics through controlled microstructural modification.

Mechanisms of Springback Control in Skin Pass Operations

The effectiveness of skin pass technology lies in its ability to modify the steel's yield point elongation behavior. During conventional cold rolling, steel develops a distinct yield point where deformation transitions from elastic to plastic behavior. This yield point elongation causes Luders bands and contributes significantly to springback effects. The skin pass process eliminates this phenomenon by introducing just enough plastic deformation to create a uniform dislocation network throughout the material.

In metallurgical terms, the minimal reduction of skin pass rolling achieves several simultaneous improvements. It creates a more homogeneous stress distribution through the strip thickness while stabilizing the material against subsequent deformation. The process essentially "conditions" the steel, making it more predictable during stamping, bending, and other fabrication processes. This explains why automotive manufacturers particularly value skin-passed material for complex body panel stamping where dimensional accuracy is critical.

Technical Implementation in Modern Skin Pass Mills

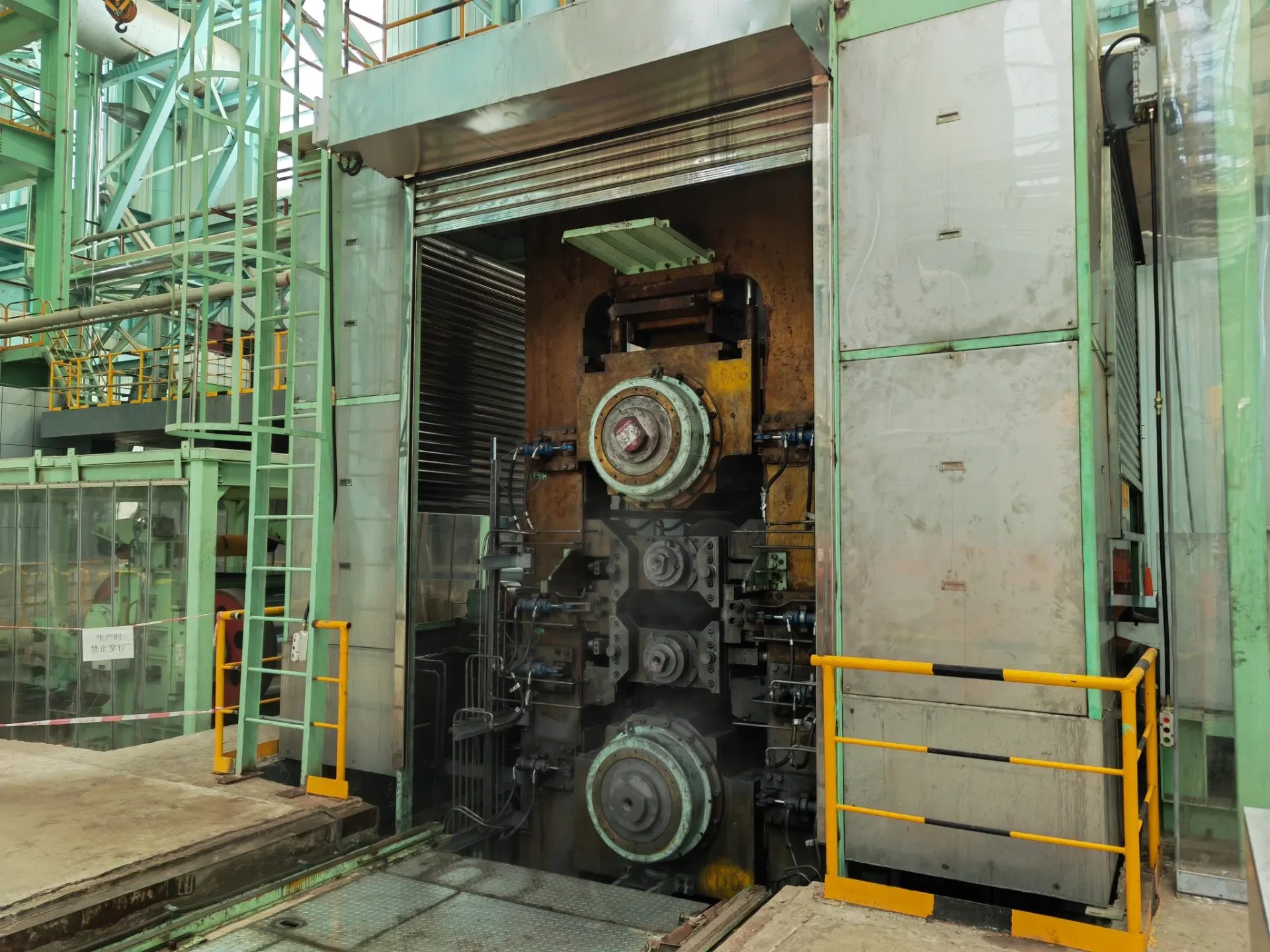

Contemporary skin pass mill designs incorporate multiple advanced technologies to achieve precise control. The mills feature work rolls with specialized surface textures that can be precisely controlled to impart specific surface characteristics while maintaining the material's dimensional stability. These textures range from smooth polished finishes for premium painted surfaces to distinctive patterns that enhance paint adhesion or lubrication retention.

The hot skin pass mill variant addresses specific challenges with temperature-sensitive alloys. By operating at elevated temperatures, these mills can process materials that would otherwise work-harden excessively during cold processing. The thermal energy helps maintain ductility while still achieving the desired microstructural modifications. This approach proves particularly valuable for certain stainless steel grades and electrical steels where cold working might promote undesirable phase transformations.

Skin Pass Mills: Process Control and Quality Assurance

The success of skin pass technology hinges on precise control in strip rolling parameters. Modern systems continuously monitor and adjust multiple variables including rolling force, tension, and speed to maintain consistent results across the entire coil length. Advanced sensor systems provide real-time feedback on strip flatness, allowing for instantaneous corrections to roll bending and tension adjustments.

This level of control becomes especially critical when processing advanced high-strength steels where the window for optimal processing parameters is narrow. The skin pass operation must impart enough deformation to stabilize the material without compromising its mechanical properties or surface quality. Sophisticated control algorithms balance these competing demands, often incorporating predictive models that anticipate material behavior based on upstream processing history.

Skin Pass Mills: Impact on Downstream Fabrication Processes

The benefits of proper skin pass treatment extend far beyond the steel mill. Fabricators experience significantly improved consistency in stamping operations, with reduced incidence of springback-related defects. The more predictable material behavior allows for tighter tolerances in formed components and reduces the need for secondary correction operations.

In automotive applications, the combination of dimensional stability and controlled surface texture proves particularly valuable. Skin-passed material provides the ideal substrate for painting processes, offering both excellent adhesion and consistent reflectivity. The process also enhances the steel's performance in high-speed stamping operations where consistent friction characteristics are essential.

The Indispensable Nature of Skin Pass Technology

Skin pass technology has evolved from a simple finishing operation to a critical metallurgical process that fundamentally enhances steel performance. By addressing the root causes of springback and dimensional instability, skin pass rolling enables the production of steel products that meet increasingly demanding application requirements. As steel continues to advance into higher strength grades and more sophisticated applications, the importance of precise skin pass treatment will only grow.

The ongoing development of skin pass mill technology ensures that steel producers can meet these challenges while maintaining the strictest quality standards. From automotive body panels to precision appliances and beyond, skin-passed steel provides the foundation for high-performance manufactured products across industries. This technology represents a perfect marriage of metallurgical science and precision engineering, delivering tangible benefits throughout the manufacturing value chain.

-

YWLX’s 1450mm Six-Hi Reversing Mill Goes Live in BangladeshNewsNov.24,2025

-

Adjusting Roll Gap in 6Hi Reversing Cold Rolling Mill for Thin StripNewsNov.13,2025

-

Quality Control Standards for Automatic Gauge Control in Strip RollingNewsNov.13,2025

-

Effect of Skin Pass Rolling on Metal DuctilityNewsNov.13,2025

-

Key Components of a Modern TempermillNewsNov.13,2025

-

Common Wear Patterns of Work Roll in Tandem Cold Mill OperationsNewsNov.13,2025

-

Revolutionary Skin Pass Rolling Technology for Enhanced Steel QualityNewsNov.04,2025