Emerging Applications of Skin Pass Rolling in EV Battery Shell Steel Production

The electric vehicle revolution has created unprecedented demand for high-performance battery shell steel, where skin pass rolling technology plays a pivotal role in meeting stringent quality requirements. As automakers seek lighter yet stronger battery enclosures, steel producers are adapting traditional hot skin pass mill operations to serve this emerging market. The precise surface treatment and mechanical property adjustment achieved through skin pass processes have become indispensable for producing battery shell materials that combine formability with structural integrity. This specialized application represents a significant evolution from conventional skin pass rolling applications in automotive body panels or appliances, requiring tighter tolerances and more consistent surface characteristics to ensure proper battery performance and safety.

Skin Pass Rolling Material Requirements for EV Battery Shell Applications

The transition to electric vehicles has established new benchmarks for steel used in battery enclosures, driving innovations in skin pass technology. EV battery shells demand materials with exceptional surface uniformity to prevent micro-short circuits while maintaining precise mechanical properties for crash protection. Modern hot skin pass mill configurations are being optimized to deliver these characteristics through controlled reductions typically between 0.5% to 3%. The process must eliminate yield point elongation while creating the ideal surface topography for subsequent coating processes. Unlike conventional applications where skin pass rolling primarily addresses cosmetic requirements, battery shell production requires a holistic approach that considers electrical properties, thermal conductivity, and mechanical performance simultaneously.

Skin Pass Rolling Surface Quality Imperatives in Battery Shell Production

The surface perfection achieved through advanced skin pass operations takes on new significance in EV battery applications. Even microscopic imperfections that might be acceptable in other applications can compromise battery performance when they occur on enclosure materials. State-of-the-art hot skin pass mill installations now incorporate enhanced surface inspection systems that go beyond traditional roughness measurements to detect potential problem areas. The skin pass rolling process must create surfaces free of defects while maintaining consistent friction characteristics - a critical factor in battery assembly processes. This represents a substantial technical challenge as the required surface characteristics must be achieved without compromising the material's structural or electrical properties.

Precision Thickness Control Through Modern Skin Pass Operations

The dimensional precision requirements for battery shell steel have pushed skin pass technology to new levels of accuracy. Contemporary hot skin pass mill installations feature advanced gauge control systems capable of maintaining thickness tolerances within ±0.5μm, a necessity for ensuring proper battery stack dimensions. The skin pass rolling process must compensate for material variations from previous processing steps while delivering exceptional flatness crucial for battery assembly automation. These tight tolerances are maintained across the entire coil length, requiring sophisticated control algorithms that account for thermal expansion, roll wear, and other dynamic process variables. The resulting consistency is essential for automated battery production lines where dimensional variations can cause assembly issues or performance compromises.

Skin Pass Rolling: Integration with Downstream Processing Equipment

The modern skin pass line for battery shell production has evolved into a sophisticated processing center that integrates seamlessly with downstream operations. Following the hot skin pass mill, materials typically proceed directly to precision slitting and automatic packaging machine systems configured specifically for battery industry requirements. This integrated approach minimizes handling and prevents surface damage to the sensitive materials. The skin pass rolling parameters are carefully coordinated with subsequent processing steps, ensuring optimal material properties for the exact battery design requirements. This level of process integration represents a significant advancement from traditional skin pass operations, where the material might undergo multiple handlings before final use.

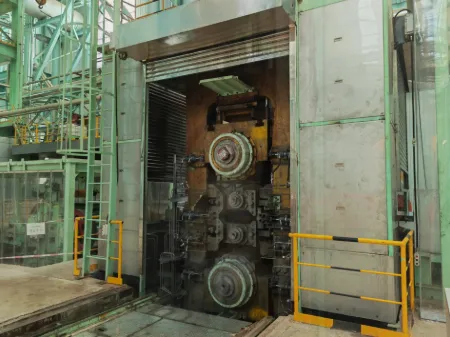

Skin Pass Rolling: Backup Roller Innovations for Enhanced Surface Quality

The quality demands of battery shell steel have driven substantial innovations in backup roller technology for skin pass applications. Modern hot skin pass mill installations utilize specially engineered backup roller systems that maintain exceptional roll surface quality over extended production runs. These advanced roller systems incorporate new materials and coatings that resist wear while maintaining precise surface reproduction characteristics. The backup roller configurations are optimized to minimize deflection and ensure consistent pressure distribution across the strip width - critical factors for achieving the uniform surface properties required in battery applications. These technological advancements in roller technology have become enablers for meeting the stringent quality standards of premium battery manufacturers.

Automated Quality Assurance in Skin Pass Lines

The integration of sophisticated inspection systems with skin pass rolling operations has become standard practice in battery shell production. Modern hot skin pass mill lines incorporate automated surface scanning systems that verify quality parameters in real-time, feeding data back to adjust process parameters as needed. This closed-loop quality control is essential for maintaining the exceptionally high standards required for battery applications. The inspection systems go beyond traditional surface monitoring to include micro-topography analysis and defect detection capabilities that were previously only available in laboratory settings. This automated quality assurance, combined with precision skin pass control, ensures consistent material properties throughout production runs that might include dozens of coils destined for battery production.

Skin Pass Rolling: Packaging and Handling Considerations for Battery Steel

The final steps in the skin pass process chain have gained new importance in battery steel production, where surface preservation is critical. Advanced automatic packaging machine systems designed specifically for battery materials employ non-contact handling methods and specialized protective films to prevent any surface damage. These systems interface directly with the hot skin pass mill control systems to ensure proper material tracking and quality documentation throughout the packaging process. The automatic packaging machine configurations for battery steel often include additional protective measures such as inert gas environments or special interleaf materials that prevent surface reactions during storage and transport. This attention to post-processing handling represents a significant evolution from traditional skin pass rolling operations where such extreme protective measures were rarely necessary.

Skin Pass Rolling as a Key Enabler for EV Battery Advancement

The specialized application of skin pass technology in EV battery shell production demonstrates how traditional steel processing methods can be adapted to serve cutting-edge industries. The precision and control offered by modern hot skin pass mill installations have become essential for meeting the extraordinary quality demands of battery manufacturers. From advanced backup roller systems to integrated automatic packaging machine solutions, every aspect of the skin pass rolling process has been refined to serve this demanding application. As the electric vehicle market continues its rapid growth, the role of precision skin pass technology in enabling better, safer, and more efficient batteries will only increase in importance. This specialized application represents not just an evolution of traditional steel processing, but a reimagining of how precision cold rolling can contribute to sustainable transportation solutions.

-

YWLX’s 1450mm Six-Hi Reversing Mill Goes Live in BangladeshNewsNov.24,2025

-

Adjusting Roll Gap in 6Hi Reversing Cold Rolling Mill for Thin StripNewsNov.13,2025

-

Quality Control Standards for Automatic Gauge Control in Strip RollingNewsNov.13,2025

-

Effect of Skin Pass Rolling on Metal DuctilityNewsNov.13,2025

-

Key Components of a Modern TempermillNewsNov.13,2025

-

Common Wear Patterns of Work Roll in Tandem Cold Mill OperationsNewsNov.13,2025

-

Revolutionary Skin Pass Rolling Technology for Enhanced Steel QualityNewsNov.04,2025