Controlling Surface Friction With Skin Pass Rolling: Why It Matters

In the world of flat-rolled metal products, surface characteristics often determine a material's performance in final applications. The skin pass mill has emerged as an indispensable finishing process that bridges the gap between metallurgical properties and surface functionality. This delicate operation serves a far greater purpose than simple gauge adjustment—it fundamentally alters how metal interacts with the world around it.

The science behind skin pass rolling reveals why this subtle process carries such substantial commercial implications. When metal sheets exit primary cold rolling or annealing processes, their surfaces often exhibit undesirable characteristics—excessive smoothness that prevents proper paint adhesion, or microscopic irregularities that cause friction issues in forming operations. The hot skin pass mill variant addresses additional challenges unique to hot-rolled products, demonstrating the versatility of this technology across different production stages.

The Friction Modulation Mechanism in Skin Passing

At its core, the skin pass process works through controlled surface deformation. As the metal passes through the work rolls under carefully regulated tension, the microscopic peaks and valleys on the sheet surface undergo plastic deformation. This creates a specific surface topography that engineering teams can precisely tailor for different applications. The control in strip rolling parameters during skin passing—including roll force, tension, and speed—must be exquisitely balanced to achieve the desired friction characteristics without compromising other material properties.

The relationship between surface roughness and friction coefficient follows complex tribological principles. A polished surface might seem ideal for reducing friction, but in practice, excessively smooth surfaces can lead to galling during metal forming operations. Conversely, excessive roughness increases friction unnecessarily. The skin pass rolling process finds the optimal middle ground by creating controlled asperities that provide just enough "tooth" for subsequent processing while maintaining smooth visual appearance.

Skin Passing: Operational Parameters That Define Surface Performance

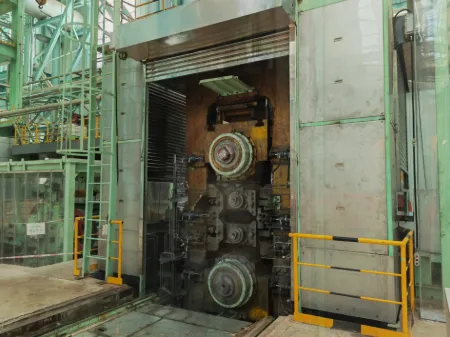

Modern skin pass mill technology offers unprecedented control over surface characteristics through several key variables. Roll surface preparation stands as the first determinant—work rolls may be ground, blasted, or laser-textured to impart specific roughness patterns. The degree of reduction, while small, must be precisely calibrated; too little leaves the surface unchanged, while too much can erase the carefully created texture.

Tension control in strip rolling during skin passing proves equally critical. Proper tension ensures uniform deformation across the strip width while preventing shape defects. Advanced mills now incorporate closed-loop control systems that continuously adjust these parameters based on real-time surface measurement feedback. The emergence of hot skin pass mill configurations has expanded these capabilities to hot-rolled products, where oxide scale behavior adds another layer of complexity to surface engineering.

Application-Specific Surface Engineering of Skin Passing

The automotive industry provides perhaps the most compelling case study for the importance of controlled friction through skin pass rolling. Body panel stamping operations demand precise friction characteristics—too little causes metal flow control issues during deep drawing, while excessive friction leads to tearing. The tailored surfaces produced by modern skin pass mill operations enable consistent formability across complex part geometries.

In appliance manufacturing, the requirements shift toward paint adhesion and visual quality. Here, the skin pass process creates surfaces that optimize coating bonding while maintaining reflective qualities. Electrical steel producers face yet another set of challenges, where surface texture must balance punchability against core loss performance in electromagnetic applications.

Skin Passing: Technological Advances in Surface Control

Recent innovations in skin pass rolling technology have focused on achieving even greater precision in surface engineering. Laser-interferometer-based surface measurement systems now provide real-time feedback to mill controls, enabling dynamic adjustment of process parameters. Some advanced mills incorporate work rolls with variable crown systems that can adjust surface texture patterns across the strip width to compensate for edge effects.

The development of hot skin pass mill technology has opened new possibilities for inline surface conditioning of hot-rolled products. By integrating skin passing directly after cooling sections, producers can eliminate separate processing steps while achieving superior surface consistency. These systems must account for the unique challenges of hot working, including scale behavior and thermal expansion effects on roll gaps.

Skin Passing: Quality Implications Across the Value Chain

The consequences of proper friction control in strip rolling extend far beyond the mill itself. Downstream manufacturers rely on consistent surface characteristics to maintain stable production processes. In coil coating lines, improper surface preparation leads to coating defects that may only become apparent after expensive painting operations. Metal formers see the impact in tool wear rates and process stability—variations in incoming material friction characteristics can necessitate frequent press adjustments.

These quality considerations have made skin pass mill certification a critical supplier qualification criterion for many high-end metal consumers. Producers who can demonstrate tight control over surface friction parameters command premium pricing and secure long-term supply agreements, particularly in automotive and specialty appliance markets.

-

YWLX’s 1450mm Six-Hi Reversing Mill Goes Live in BangladeshNewsNov.24,2025

-

Adjusting Roll Gap in 6Hi Reversing Cold Rolling Mill for Thin StripNewsNov.13,2025

-

Quality Control Standards for Automatic Gauge Control in Strip RollingNewsNov.13,2025

-

Effect of Skin Pass Rolling on Metal DuctilityNewsNov.13,2025

-

Key Components of a Modern TempermillNewsNov.13,2025

-

Common Wear Patterns of Work Roll in Tandem Cold Mill OperationsNewsNov.13,2025

-

Revolutionary Skin Pass Rolling Technology for Enhanced Steel QualityNewsNov.04,2025