Common Applications of Skin Pass Mills in Cold Rolled Steel Production

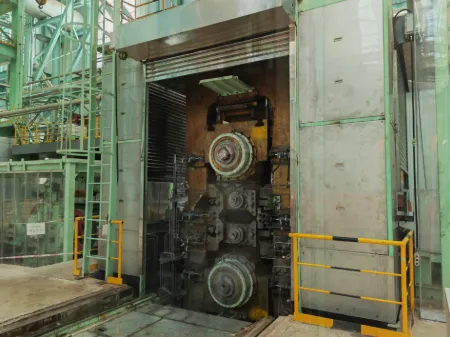

The production of cold-rolled steel requires precise finishing processes to achieve the desired mechanical properties and surface quality. Among these processes, skin pass rolling plays a critical role in enhancing the final product's characteristics. A skin pass mill, also known as a temper mill, is a specialized rolling machine that applies a light reduction (typically 0.5% to 3%) to cold-rolled steel sheets. This process refines the material's surface, improves flatness, and enhances mechanical properties without significantly altering thickness.

The hot skin pass mill variant is used for certain applications where thermal treatment is combined with light rolling to optimize steel properties. Additionally, steel conveyor rollers facilitate the smooth movement of steel coils through the skin pass mill, ensuring consistent processing.

The Role of Skin Pass Rolling in Surface Improvement

One of the primary functions of a skin pass mill is to enhance the surface finish of cold-rolled steel. After the initial cold rolling process, steel sheets may exhibit minor imperfections such as roughness, mill scale residues, or uneven textures. Skin pass rolling addresses these issues by applying controlled pressure, which refines the surface and imparts a uniform matte or glossy finish, depending on customer requirements.

1. Eliminating Yield Point Elongation

Cold-rolled steel can develop a phenomenon called yield point elongation, which leads to uneven deformation during stamping or forming. A skin pass mill introduces slight plastic deformation, eliminating this issue and ensuring smoother forming operations in automotive and appliance manufacturing.

2. Enhancing Paint Adhesion and Coating Uniformity

For steel used in painted or coated applications (e.g., automotive bodies or household appliances), surface quality is crucial. The skin pass process creates micro-textures that improve paint adhesion and prevent defects like orange peel or blistering.

3. Reducing Stretcher Strains and Fluting

Without skin pass rolling, cold-rolled steel sheets may develop visible stretcher strains or fluting during deep drawing. The light reduction applied by the mill minimizes these defects, ensuring a defect-free surface for high-end applications.

Applications of Skin Pass Mills in Different Industries

The versatility of skin pass rolling makes it indispensable across multiple industries that rely on cold-rolled steel. Below are some of the most common applications:

1. Automotive Industry: High-Strength Steel for Body Panels

Automakers demand steel with excellent formability and surface quality for body panels, doors, and structural components. A hot skin pass mill is sometimes used for advanced high-strength steels (AHSS) to optimize mechanical properties while maintaining surface integrity. The process ensures that the steel can undergo deep drawing and stamping without cracking or surface defects.

2. Appliances and Consumer Electronics

Household appliances (refrigerators, washing machines) and electronics (laptop casings, smartphone frames) require steel with a flawless surface finish. Skin pass rolling refines the steel to meet aesthetic and functional standards, ensuring resistance to scratches and corrosion.

3. Construction and Architectural Cladding

For construction applications such as roofing, wall panels, and structural components, skin pass mills improve flatness and prevent waviness. The process also enhances the steel's resistance to environmental factors, making it suitable for exterior use.

4. Packaging Industry: Tinplate and DR Steel

In food and beverage packaging, tinplate and double-reduced (DR) steel must have a smooth, uniform surface for printing and corrosion resistance. Skin pass rolling ensures that the steel meets stringent quality standards for can manufacturing.

The Importance of Steel Conveyor Rollers in Skin Pass Mills

A well-functioning skin pass mill relies on an efficient material handling system, where steel conveyor rollers play a vital role. These rollers guide the steel coils through the mill, ensuring precise alignment and tension control. Key functions include:

Maintaining Consistent Strip Tension: Proper tension prevents wrinkling or stretching during skin pass rolling.

Ensuring Smooth Transitions Between Processes: The rollers facilitate seamless movement from uncoiling to recoiling after processing.

Reducing Surface Damage: High-quality steel conveyor rollers are designed to minimize scratches or marks on the steel surface.

Advanced mills use automated roller systems with precision controls to optimize the skin pass process, reducing downtime and improving efficiency.

Hot Skin Pass Mills: Combining Thermal and Mechanical Treatment

While most skin pass mills operate at room temperature, some applications benefit from a hot skin pass mill, which combines light rolling with controlled heating. This hybrid process is particularly useful for:

High-Strength Low-Alloy (HSLA) Steels: Improves ductility while maintaining strength.

Grain Structure Refinement: Enhances mechanical properties for demanding applications.

Stress Relief: Reduces internal stresses in steel that has undergone severe cold working.

The hot skin pass mill is less common than conventional skin pass mills but offers unique advantages for specialized steel grades.

The Indispensable Role of Skin Pass Mills

From automotive manufacturing to consumer electronics, skin pass mills are essential for producing high-quality cold-rolled steel. By refining surface finish, improving mechanical properties, and preventing defects, skin pass rolling ensures that steel meets the stringent requirements of various industries.

The integration of steel conveyor rollers and emerging technologies like the hot skin pass mill further enhances the efficiency and capabilities of modern steel processing. As the industry advances, skin pass technology will continue to play a pivotal role in delivering superior steel products for a wide range of applications.

-

YWLX’s 1450mm Six-Hi Reversing Mill Goes Live in BangladeshNewsNov.24,2025

-

Adjusting Roll Gap in 6Hi Reversing Cold Rolling Mill for Thin StripNewsNov.13,2025

-

Quality Control Standards for Automatic Gauge Control in Strip RollingNewsNov.13,2025

-

Effect of Skin Pass Rolling on Metal DuctilityNewsNov.13,2025

-

Key Components of a Modern TempermillNewsNov.13,2025

-

Common Wear Patterns of Work Roll in Tandem Cold Mill OperationsNewsNov.13,2025

-

Revolutionary Skin Pass Rolling Technology for Enhanced Steel QualityNewsNov.04,2025