Combining Pickling and Skin Pass for Enhanced Surface Treatment

Modern steel processing has evolved to recognize the complementary benefits of combining pickling with skin pass rolling operations to achieve superior surface quality. This integrated approach leverages the strengths of both processes to create material surfaces that meet increasingly demanding industrial specifications. The pickling stage effectively removes scale and surface impurities, while the subsequent skin pass operation in a hot skin pass mill provides precise control over mechanical properties and surface topography. Together, these processes create steel products with optimized characteristics for critical applications ranging from automotive panels to premium appliances. The strategic combination has become particularly valuable in producing high-end flat steel products where surface perfection is paramount.

Process Integration: From Pickling to Skin Pass Rolling

The seamless transition from pickling to skin pass rolling represents a significant advancement in continuous processing lines. Modern tandem lines now incorporate both processes in sequence, allowing for efficient material flow and consistent quality control. After emerging from the pickling section where oxides are chemically removed, the steel strip proceeds directly to the hot skin pass mill where it undergoes controlled plastic deformation. This integrated approach minimizes intermediate handling that could potentially damage the freshly pickled surface. The coordination between these stages requires precise tension control and careful synchronization of line speeds to ensure the delicate pickled surface enters the skin pass operation under optimal conditions. The result is a streamlined process that enhances both efficiency and final product quality.

Skin Pass Rolling Surface Enhancement Through Combined Treatment

The combination of pickling and skin pass operations produces surface characteristics unattainable through either process alone. Pickling provides the clean, chemically uniform starting surface that allows the hot skin pass mill to impart precisely controlled topography. The light reduction (typically 0.5-3%) during skin pass rolling creates the desired matte finish while eliminating yield point elongation that could cause stretcher strains in subsequent forming operations. This dual treatment is particularly effective for applications requiring both exceptional cleanliness and controlled surface roughness, such as exposed automotive panels or high-visibility appliance components. The process combination also enhances paint adhesion and coating uniformity in downstream finishing operations.

Skin Pass Rolling: Mechanical Property Optimization

Beyond surface treatment, the pickling and skin pass combination provides unparalleled control over mechanical properties. The hot skin pass mill can precisely adjust yield strength and hardness characteristics after the pickling process has ensured uniform material composition. This sequential treatment allows manufacturers to tailor mechanical properties to specific customer requirements while maintaining tight tolerances. The process is especially valuable for producing drawing-quality steels where controlled work hardening during skin pass rolling improves formability without compromising strength characteristics. The elimination of yield point elongation through the skin pass operation prevents Lüders lines from appearing during forming operations, ensuring superior surface quality in finished products.

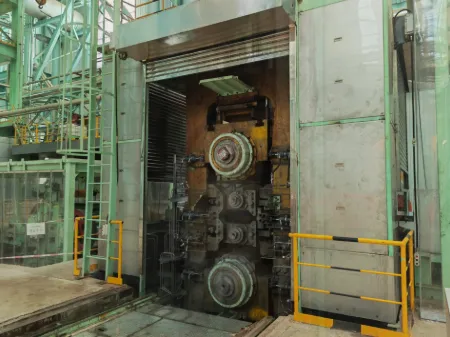

Skin Pass Rolling: Equipment Innovations for Combined Processing

Modern processing lines have seen significant equipment innovations to optimize the pickling and skin pass rolling combination. Advanced hot skin pass mill designs now incorporate features specifically engineered for handling pickled material, including specialized backup roller systems that maintain precise roll gap control. The backup roller technology has evolved to provide exceptional stability and vibration damping, critical for maintaining surface quality on the delicate pickled strip. These mills often feature enhanced roll cooling systems and advanced shape control capabilities to handle the unique characteristics of pickled material. The integration extends to the automatic packaging machine at the line's end, which is configured to handle the finished product without compromising the carefully created surface characteristics.

Skin Pass Rolling: Quality Control in Combined Processing Lines

The marriage of pickling and skin pass operations demands sophisticated quality control systems to monitor both processes simultaneously. Modern lines employ advanced surface inspection technology that verifies pickling completeness before the material enters the hot skin pass mill. During skin pass rolling, additional sensors monitor surface topography, flatness, and mechanical properties in real time. This comprehensive monitoring ensures that any deviations can be corrected immediately, maintaining consistent quality throughout production runs. The data from these systems also feeds forward to the automatic packaging machine, allowing for intelligent coil identification and tracking based on verified quality parameters rather than just process settings.

Environmental and Efficiency Benefits of Skin Pass Rolling

Combining pickling with skin pass rolling in continuous processing lines offers significant environmental and operational efficiency advantages. The integrated approach reduces energy consumption by eliminating the need to separately reheat coils between processes. It also minimizes handling and associated surface damage risks that could occur if the processes were performed separately. Modern hot skin pass mill configurations in these combined lines feature energy recovery systems that capture and reuse process heat, further enhancing sustainability. The reduced material movement between processes also decreases the carbon footprint associated with transportation within the plant, making the combined approach both economically and environmentally advantageous.

Applications Demanding Combined Treatment of Skin Pass Rolling

The pickling plus skin pass treatment has become essential for numerous high-end applications where surface quality cannot be compromised. Automotive exposed panels represent one of the most demanding applications, requiring surfaces free of both chemical impurities and topological defects. The appliance industry, particularly for premium refrigerator and dishwasher exteriors, similarly benefits from this dual treatment. Emerging applications in architectural cladding and specialty packaging materials are also driving adoption of the combined process. In all these cases, the skin pass rolling operation following pickling provides the final surface refinement that distinguishes premium products from standard offerings. The process combination has proven particularly valuable for materials that will undergo subsequent coating or painting operations.

Skin Pass Rolling: The Value of Integrated Surface Treatment

The strategic combination of pickling and skin pass rolling has established itself as a gold standard for high-quality steel production. By integrating these processes in continuous processing lines featuring advanced hot skin pass mill technology, manufacturers achieve surface characteristics and mechanical properties that would be difficult or impossible to obtain through separate treatments. The synergy between chemical surface cleaning and controlled mechanical working creates products that meet the most stringent industry requirements while maintaining production efficiency. As end-user demands for perfect surfaces continue to grow across multiple industries, the combined pickling and skin pass approach will remain a critical capability for steel producers seeking to deliver premium quality products. The ongoing evolution of this technology, from backup roller innovations to intelligent automatic packaging machine systems, ensures its continued relevance in an increasingly quality-conscious marketplace.

-

YWLX’s 1450mm Six-Hi Reversing Mill Goes Live in BangladeshNewsNov.24,2025

-

Adjusting Roll Gap in 6Hi Reversing Cold Rolling Mill for Thin StripNewsNov.13,2025

-

Quality Control Standards for Automatic Gauge Control in Strip RollingNewsNov.13,2025

-

Effect of Skin Pass Rolling on Metal DuctilityNewsNov.13,2025

-

Key Components of a Modern TempermillNewsNov.13,2025

-

Common Wear Patterns of Work Roll in Tandem Cold Mill OperationsNewsNov.13,2025

-

Revolutionary Skin Pass Rolling Technology for Enhanced Steel QualityNewsNov.04,2025