Steel Strip Mill Manufacturing Innovative Solutions for High-Quality Production

The Steel Strip Mill Driving Innovation in Metal Processing

In today's rapidly evolving industrial landscape, the steel strip mill stands as a crucial player in the production of high-quality steel strips essential for various applications. This specialized facility is not just a factory; it is a hub of innovation and technology that transforms raw steel into versatile materials used across multiple industries, from automotive manufacturing to construction.

Historical Context

The evolution of steel strip mills dates back to the industrial revolution when the demand for stronger and more durable materials surged. Early mills employed rudimentary techniques for steel production, but over decades, advancements in rolling technology led to the development of modern steel strip mills. These facilities utilize sophisticated processes to produce steel strips with precise dimensions and properties.

The Production Process

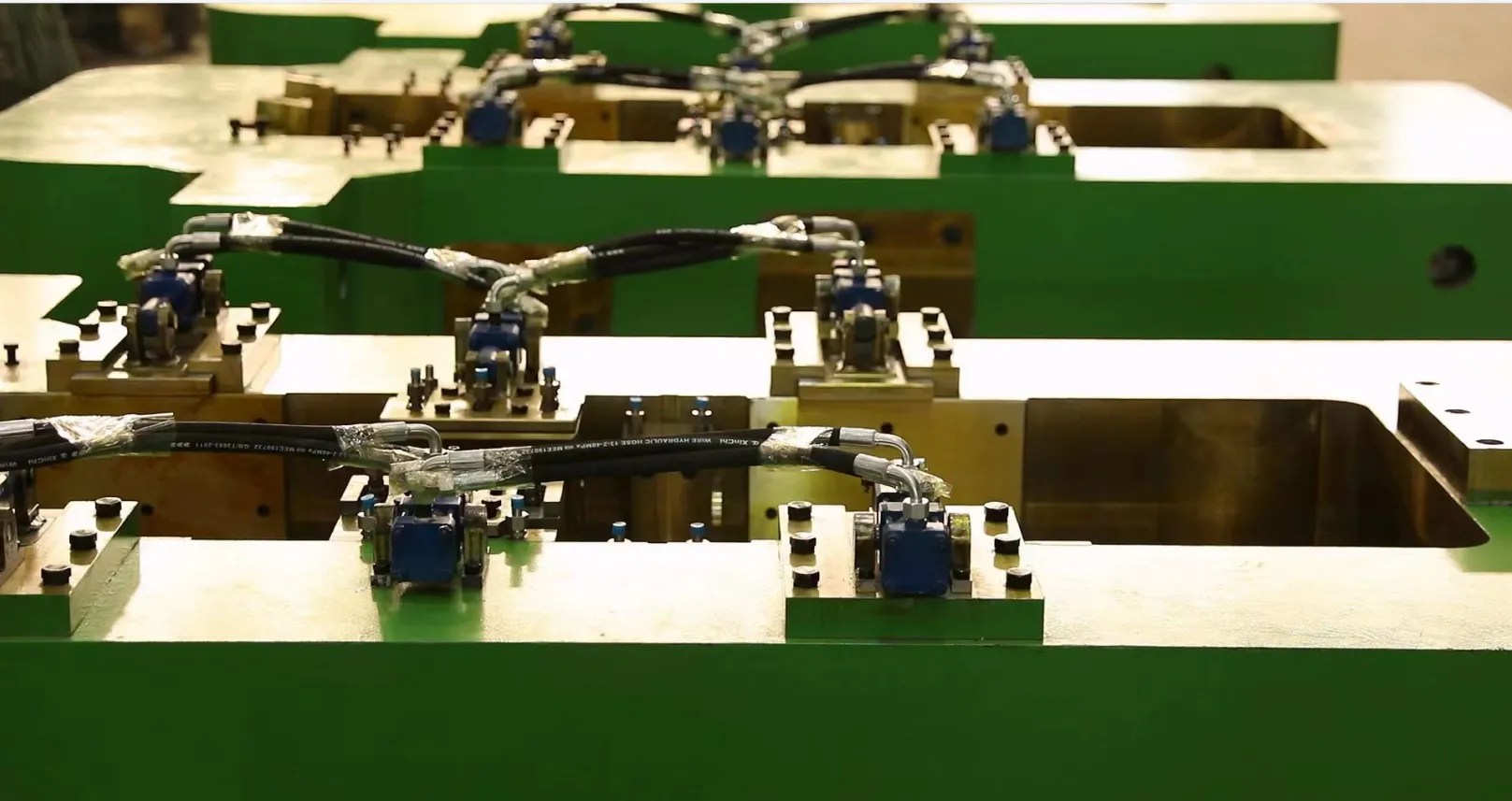

The production process in a steel strip mill involves several stages, each critical to ensuring the final product meets the required specifications. Initially, large steel slabs are heated and passed through a series of rollers. As the slabs move through these rollers, they are gradually reduced in thickness and increased in length. This process, known as hot rolling, is often followed by cold rolling, where the material is further processed at room temperature to achieve finer tolerances and improved surface finishes.

.

Applications of Steel Strips

مطحنة شرائط الصلب

Steel strips produced by these mills have a wide array of applications. In the automotive industry, they are used for structural components, body panels, and reinforcement parts. The construction sector relies on steel strips for everything from framing to roofing materials. Additionally, appliances, pipes, and even electronic devices often utilize steel strips for their durability and versatility.

With the rise of green technology, the demand for high-strength steel strips has grown. Manufacturers are increasingly looking for lightweight materials that can improve energy efficiency while maintaining structural integrity. The steel strip mill industry is responding to this trend by developing advanced high-strength steel (AHSS) that meets these modern requirements.

Future Innovations

As technology continues to advance, steel strip mills are embracing innovations that promise to enhance efficiency and sustainability. Automation plays a significant role in modern mills, with robotic systems streamlining processing and reducing labor costs. Smart manufacturing practices, powered by data analytics and the Internet of Things (IoT), allow mills to monitor production in real-time, optimizing processes for better productivity while minimizing waste.

Moreover, the industry is seeing a shift towards more sustainable practices. Steel mills are increasingly investing in technologies to reduce carbon emissions and recycle scrap steel, contributing to a circular economy. This drive toward sustainability not only meets regulatory requirements but also addresses the growing demand from consumers and businesses for environmentally friendly products.

Conclusion

The steel strip mill represents a dynamic segment of the steel industry that is crucial for various applications in our everyday lives. Through continuous innovation in technology and processes, these mills are not only meeting the demands of today’s market but are also paving the way for a more sustainable and efficient future. As industries continue to evolve, the importance of high-quality steel strips produced in these mills will undoubtedly remain significant, ensuring their role in shaping the materials that build our world.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025