Efficiency, Accuracy, and Safety with Automatic strip Packaging Machines

In the metallurgy and non-metallurgy industry, precision, efficiency, and safety are critical when it comes to packaging stage. Automatic packaging machines are designed to streamline the packaging process, ensuring that medications are safely and accurately dispensed and sealed. These machines are indispensable in improving productivity, minimizing human error, and maintaining safety standards. Much like the role of skin pass mills in the steel industry, where the skin pass process ensures the final product's uniformity and smoothness, automatic strip packaging machines optimize the consistency and safety of pharmaceutical packaging. Let’s dive into how these machines enhance efficiency, accuracy, and safety in medication packaging.

Streamlining Efficiency with Automatic Packaging Machines

One of the key advantages of automatic packaging machines is their ability to significantly enhance efficiency in steel and aluminum strip packaging. By automating the strip sorting, counting, and packaging process, these machines eliminate the need for manual labor, reducing packaging time while increasing output. Unlike traditional manual methods, where the risk of human error can slow down the process, automatic strip packaging machines operate at high speeds, ensuring that large volumes of strips are packed in a fraction of the time.

The automation of these processes allows pharmaceutical manufacturers to meet growing demand and keep up with production schedules. Furthermore, many machines are designed to handle different types and sizes of strip packaging, providing flexibility for various products, such as tablets, capsules, and soft gels. These machines can also handle multiple packaging formats, including blister packs, bottles, and sachets, increasing their versatility across the pharmaceutical industry.

Achieving Precision and Accuracy in strip Counting and Packaging

When it comes to pharmaceutical packaging, accuracy is essential to ensure that the correct number of strips is packaged in each unit. Automatic strip packaging machines are equipped with advanced sensors and counting mechanisms to ensure that the correct dosage is dispensed every time. These sensors monitor the flow of strips, adjusting for any discrepancies and ensuring that each package contains the precise amount of medication required by regulatory standards.

For example, when using blister packs, automatic strip packaging machines can individually count strips, verifying that the right amount is placed into each cavity. This automated counting process reduces the risk of overfilling or underfilling, both of which could lead to costly product recalls or, worse, patient safety issues. By enhancing accuracy, these machines provide assurance to pharmaceutical companies and patients alike that the correct dosage is being delivered consistently and reliably.

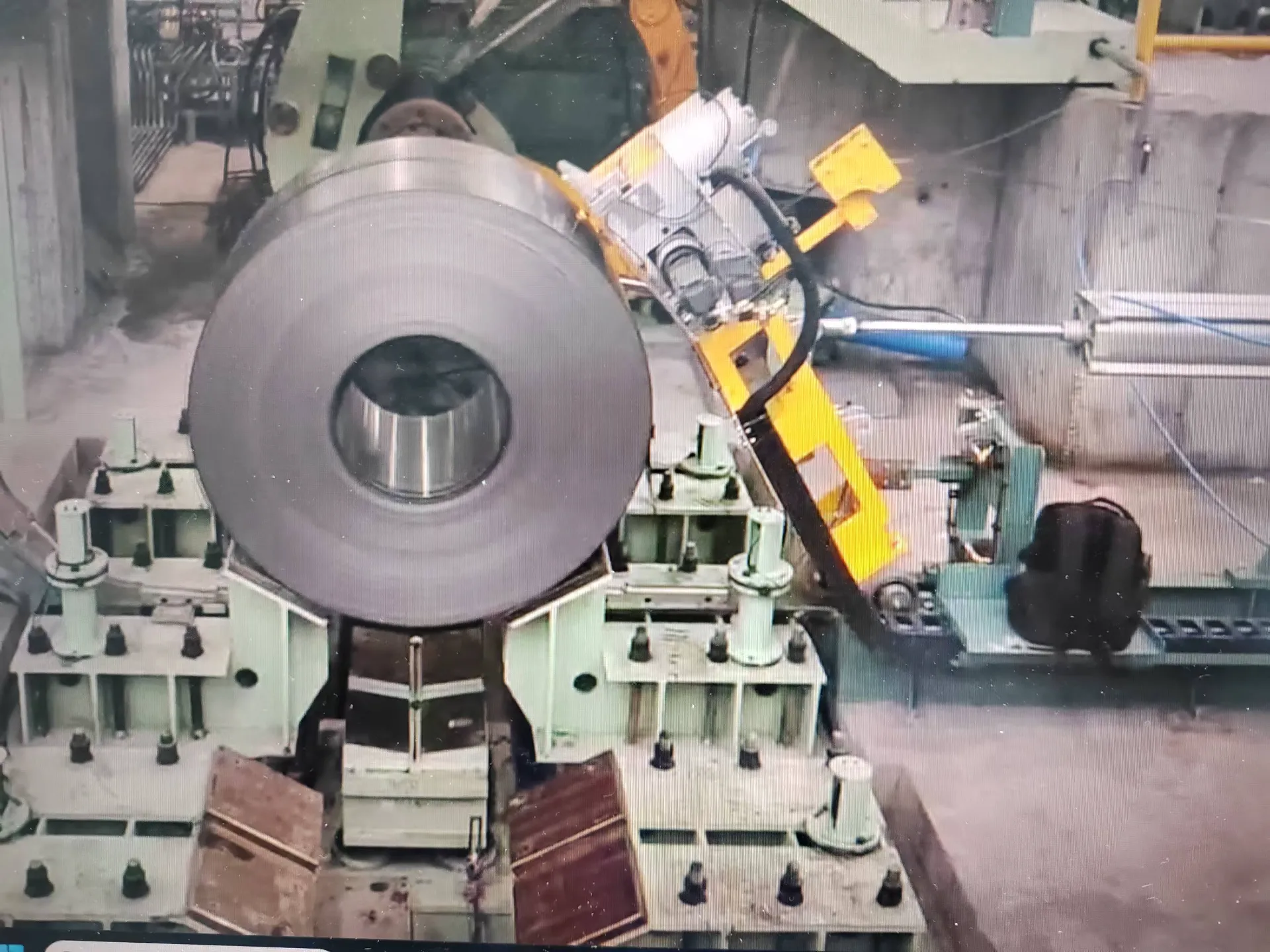

Skin Pass Mill Technology and Its Parallels to Steel Strip Packaging Efficiency

While skin pass mills are primarily used in the steel industry to improve the surface finish and mechanical properties of steel, the principles of skin pass process steel technology offer valuable insights into how automation improves manufacturing processes across different industries. In skin pass mills, the process smooths and strengthens steel to ensure consistent quality throughout production. Similarly, automatic packaging machines employ advanced technologies to smooth out the process of packing, ensuring the strips are handled with the utmost precision.

Just as skin pass mills reduce defects and improve the uniformity of steel sheets, automatic packaging machines enhance the uniformity of packaging, preventing inconsistencies in the quantity or presentation of the strips. This parallels the idea of improving the final output by automating the final stage of the production process, making it faster, safer, and more efficient.

Enhancing Safety with Automatic Packaging Machines

Safety is paramount in the steel industry, It will be risky if more workers involved in the packaging process. Automatic packaging machines help improve safety in multiple ways. First, By automating the process, they reduce the risk of manual operation. Moreover, automation minimizes the risk of injury in the workplace. reduces the likelihood of accidents in busy production environments.

Automatic strip packaging machines also integrate real-time tracking and reporting systems that monitor every step of the packaging process. This means that manufacturers can track any inconsistencies or failures immediately, addressing potential issues before they escalate. As a result, the safety of the workforce is ensured throughout the production cycle.

The Future of Automatic strip Packaging Machines: Efficiency, Accuracy, and Enhanced Safety

As the pharmaceutical industry continues to evolve, the future of automatic strip packaging machines looks promising. With the integration of cutting-edge technologies such as artificial intelligence, machine learning, and IoT (Internet of Things), these machines will only become more efficient, accurate, and safe. AI-powered systems could help predict potential failures before they occur, optimizing the maintenance schedule and preventing costly downtime. Machine learning algorithms could also improve counting accuracy by adapting to different shapes and sizes of , enhancing the overall flexibility of these machines.

Moreover, as regulatory requirements become stricter, automatic strip packaging machines will continue to play a crucial role in ensuring compliance with industry standards. These machines already comply with strict regulations, but advancements in automation and technology will allow for even greater levels of precision, helping manufacturers meet increasingly demanding packaging and labeling requirements.

In conclusion, the role of automatic strip packaging machines in enhancing efficiency, accuracy, and safety cannot be overstated. From reducing human error to improving workplace safety and ensuring high-quality medication packaging, these machines are revolutionizing the pharmaceutical packaging process. As the technology continues to advance, manufacturers can expect even more improvements in efficiency and reliability, further elevating the standard of care for patients and workers alike.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025