Suppliers of Cold Rolled Steel Products and Their Market Influence

Cold Rolling Suppliers A Comprehensive Guide

Cold rolling is a crucial process in the metalworking industry, where metal sheets and strips are transformed into thinner gauges with enhanced properties. This technique not only improves the metal's mechanical characteristics but also provides a superior surface finish. For manufacturers in need of cold-rolled products, understanding the landscape of cold rolling suppliers is essential.

Understanding the Cold Rolling Process

Cold rolling involves the deformation of metal at room temperature, making it distinct from hot rolling, which takes place at elevated temperatures. This process increases the yield strength and hardness of the metal through work hardening. The result is a product that is more durable and has a more uniform thickness than its hot-rolled counterparts. Cold-rolled steel is widely used across various industries, including automotive, construction, appliances, and furniture.

Key Considerations When Choosing Cold Rolling Suppliers

.

2. Range of Products Different applications require various grades and thicknesses of cold-rolled steel. An ideal supplier should offer a comprehensive range of products, such as cold-rolled sheets, coils, and strips in different thicknesses, widths, and grades. This diversity allows manufacturers to source all their needs from a single supplier, reducing lead times and costs.

поставщики станов холодной прокатки

3. Customization Capabilities The ability to customize products according to specific requirements can set suppliers apart in a competitive market. This includes not only variations in size and thickness but also tailored chemical compositions. Suppliers that can accommodate special requests demonstrate flexibility and a customer-centric approach.

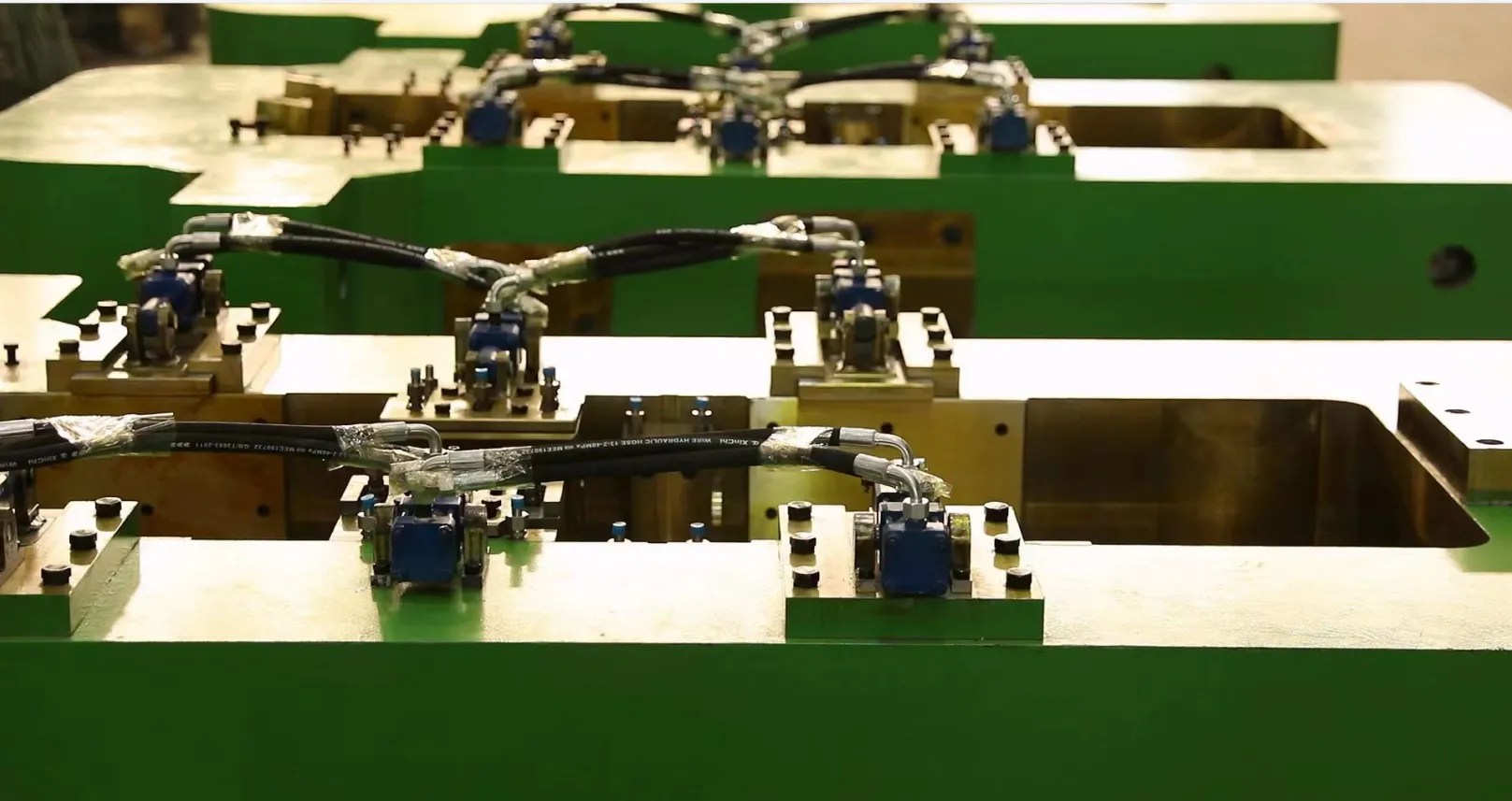

4. Technological Advancements The cold rolling process has seen significant technological advancements over the years. Suppliers who invest in modern equipment and processes can offer improved products and capabilities. Look for suppliers that utilize advanced rolling mills, automation, and sophisticated control systems to ensure consistent quality and efficiency.

5. Supply Chain Reliability A dependable supply chain is crucial for maintaining production schedules. Suppliers should have a robust logistics network and inventory management practices in place to ensure timely deliveries, especially for large orders. Building a long-term relationship with a reliable supplier can create a stable production environment.

6. Environmental Responsibility Sustainability is becoming increasingly important in all industries, including metal processing. Suppliers who adopt environmentally friendly practices, such as recycling scrap metal and reducing emissions, showcase their commitment to corporate social responsibility. This not only benefits the environment but also enhances the supplier's reputation.

The Future of Cold Rolling Suppliers

As demands for high-quality materials continue to rise, the role of cold rolling suppliers will evolve. Innovations in material science, such as high-strength steel and advanced coatings, will require suppliers to adapt continuously. Additionally, the rise of e-commerce is changing how suppliers connect with customers, making it essential to have a strong online presence and digital engagement strategies.

In conclusion, selecting the right cold rolling supplier requires careful consideration of various factors, including product quality, range, customization, technology, supply chain reliability, and environmental practices. As industries continue to grow and evolve, the collaboration between manufacturers and cold rolling suppliers will play a vital role in shaping production capabilities and material advancements. By partnering with the right supplier, businesses can enhance their operational efficiency and drive innovation in their respective fields.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025