Agc System For Hot/Cold Strip Rolling Mill

2 月 . 17, 2025 14:09

Back to list

Agc System For Hot/Cold Strip Rolling Mill

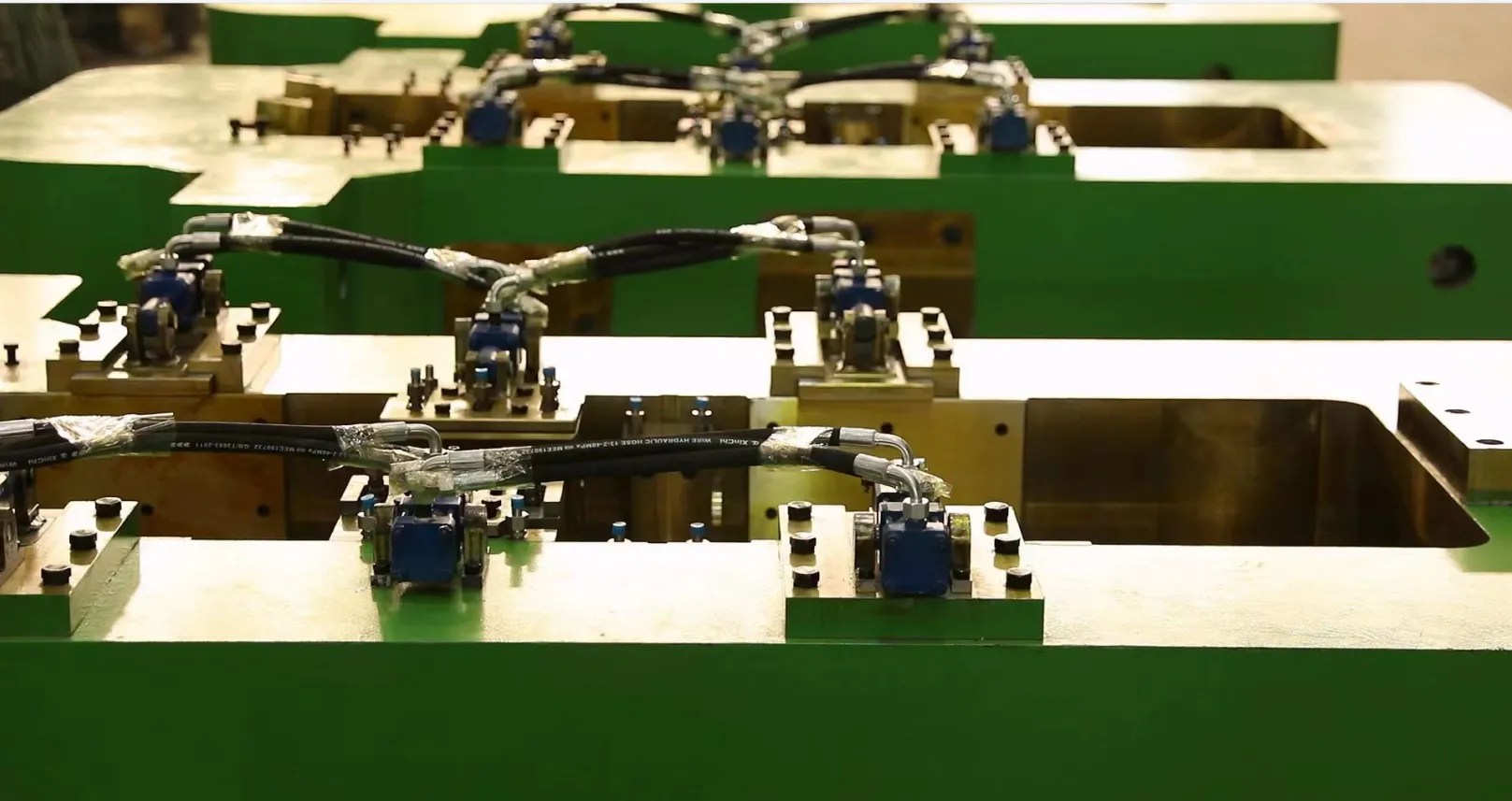

The 6000kN skin pass mill stands as a pivotal instrument in the steel manufacturing process, playing a crucial role in enhancing the surface quality and mechanical properties of metal sheets. This modern marvel of engineering is designed to deliver a powerful yet precise process that refines the end product, ensuring it meets the stringent requirements of today’s industry standards.

Authoritativeness manifests itself in the 6000kN skin pass mill via endorsements from leading metallurgical institutions and compliance with international manufacturing standards. These factors reinforce the mill’s capability to produce uniformly flattened products, ready for subsequent manufacturing stages. The mill’s authority is further cemented by its ability to incorporate innovative technologies, like real-time quality control sensors and advanced stainless steel purification processes, which set benchmarks within the industry. Trustworthiness is another hallmark of the 6000kN skin pass mill, cultivated through years of reliable operation across major steel production facilities. The manufacturers of these mills often provide extensive warranties and customer support, ensuring any investment into this technology comes with long-term assurances of performance. Feedback from multinational corporations using these mills consistently highlights the seamless integration and tangible improvement in their final product quality, thus solidifying trust within the market. In essence, the 6000kN skin pass mill is not just another tool in the steel manufacturing process; it is an integral element that enhances product integrity and value. By adopting this technology, companies position themselves at the forefront of the steel industry, equipped with the means to produce superior sheets that fulfill the exacting demands of various global sectors.

Authoritativeness manifests itself in the 6000kN skin pass mill via endorsements from leading metallurgical institutions and compliance with international manufacturing standards. These factors reinforce the mill’s capability to produce uniformly flattened products, ready for subsequent manufacturing stages. The mill’s authority is further cemented by its ability to incorporate innovative technologies, like real-time quality control sensors and advanced stainless steel purification processes, which set benchmarks within the industry. Trustworthiness is another hallmark of the 6000kN skin pass mill, cultivated through years of reliable operation across major steel production facilities. The manufacturers of these mills often provide extensive warranties and customer support, ensuring any investment into this technology comes with long-term assurances of performance. Feedback from multinational corporations using these mills consistently highlights the seamless integration and tangible improvement in their final product quality, thus solidifying trust within the market. In essence, the 6000kN skin pass mill is not just another tool in the steel manufacturing process; it is an integral element that enhances product integrity and value. By adopting this technology, companies position themselves at the forefront of the steel industry, equipped with the means to produce superior sheets that fulfill the exacting demands of various global sectors.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products