web tension control systems

Feb . 14, 2025 08:54

Back to list

web tension control systems

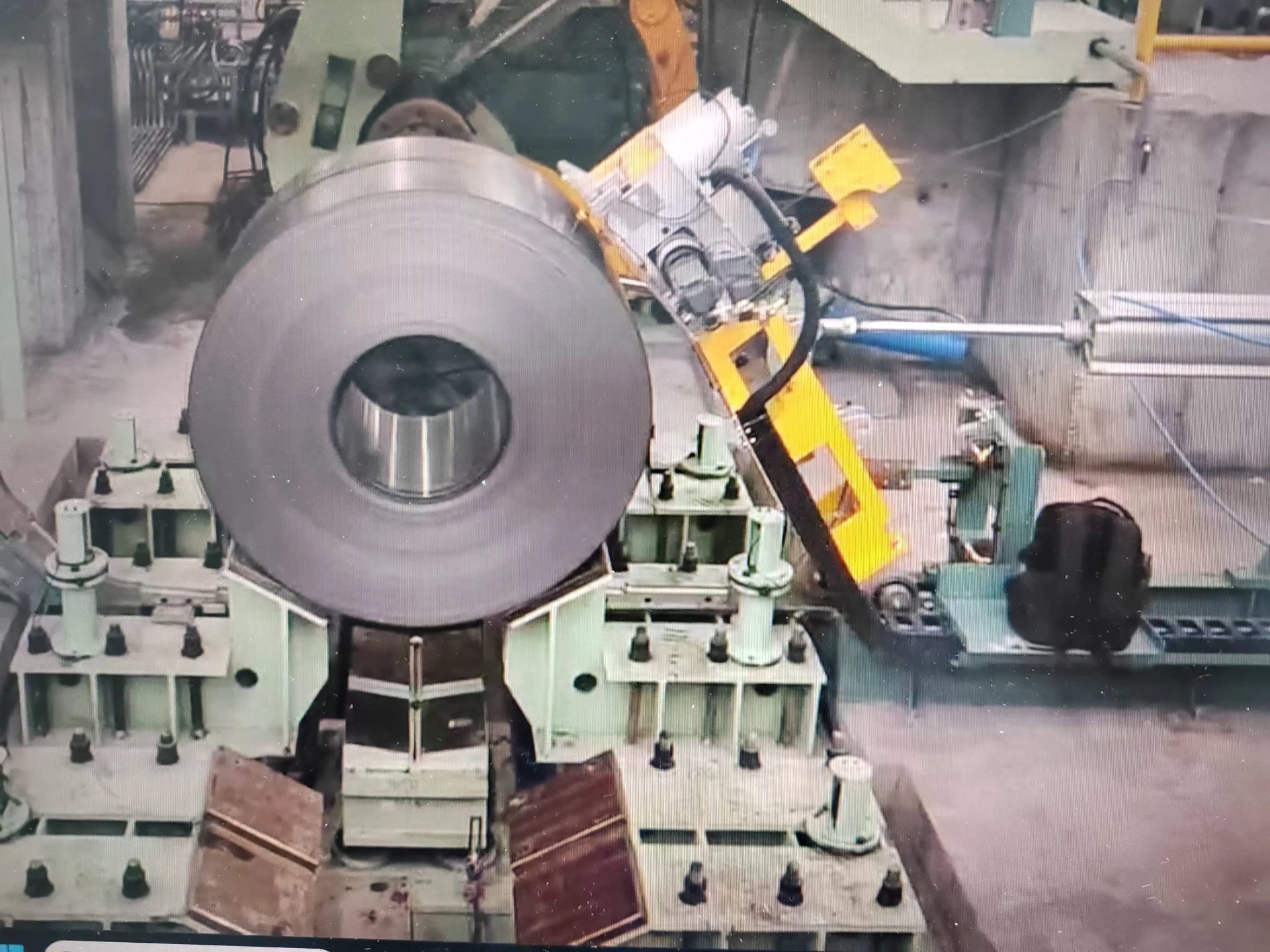

In the heart of industrial manufacturing, where precision is non-negotiable, web tension control systems wield an undeniable prowess. From paper and plastic to textiles and metals, the artistry of maintaining consistent tension across a myriad of substrates is what sets apart exemplary products. Within this niche, having hands-on experience with different web tension control systems reveals nuances that can dramatically impact production efficacy.

Additionally, a comprehensive customer support and training service accentuates trust. Manufacturers offering extensive training programs for operators, coupled with prompt technical support, ensure that their systems not only meet expectations but also adapt to evolving manufacturing requirements. Effective troubleshooting tips and a readily available knowledgeable support team can mitigate production hitches, fostering a high dependency and loyalty to the system in use. Another critical factor enhancing the trust aspect is the adaptability of the systems to various operational environs. It's crucial that these systems offer customization, accommodating an array of materials and substrate paths. A highly adaptable system ensures seamless integration with existing equipment, thereby optimizing both the operational and financial scales. Providing equipment that is easy to install and maintain is quintessential. Many manufacturers have invested in creating user-friendly systems that require minimal human intervention. Users benefit from easy-to-read interfaces, modular components for straightforward replacements, and clear diagnostics that reduce the learning curve and promote long-term operational satisfaction. In conclusion, the sphere of web tension control systems is intricately woven with precision, real-time data intelligence, and responsive adaptability. Professionals who master these dimensions not only achieve superior product quality but also streamline their production processes. With a focus on combining operational expertise with reliable, advanced systems, manufacturers championing these principles will continue to lead in innovation, trust, and authority in an ever-evolving industry landscape.

Additionally, a comprehensive customer support and training service accentuates trust. Manufacturers offering extensive training programs for operators, coupled with prompt technical support, ensure that their systems not only meet expectations but also adapt to evolving manufacturing requirements. Effective troubleshooting tips and a readily available knowledgeable support team can mitigate production hitches, fostering a high dependency and loyalty to the system in use. Another critical factor enhancing the trust aspect is the adaptability of the systems to various operational environs. It's crucial that these systems offer customization, accommodating an array of materials and substrate paths. A highly adaptable system ensures seamless integration with existing equipment, thereby optimizing both the operational and financial scales. Providing equipment that is easy to install and maintain is quintessential. Many manufacturers have invested in creating user-friendly systems that require minimal human intervention. Users benefit from easy-to-read interfaces, modular components for straightforward replacements, and clear diagnostics that reduce the learning curve and promote long-term operational satisfaction. In conclusion, the sphere of web tension control systems is intricately woven with precision, real-time data intelligence, and responsive adaptability. Professionals who master these dimensions not only achieve superior product quality but also streamline their production processes. With a focus on combining operational expertise with reliable, advanced systems, manufacturers championing these principles will continue to lead in innovation, trust, and authority in an ever-evolving industry landscape.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products