walzwerkfertigung

Feb . 13, 2025 10:15

Back to list

walzwerkfertigung

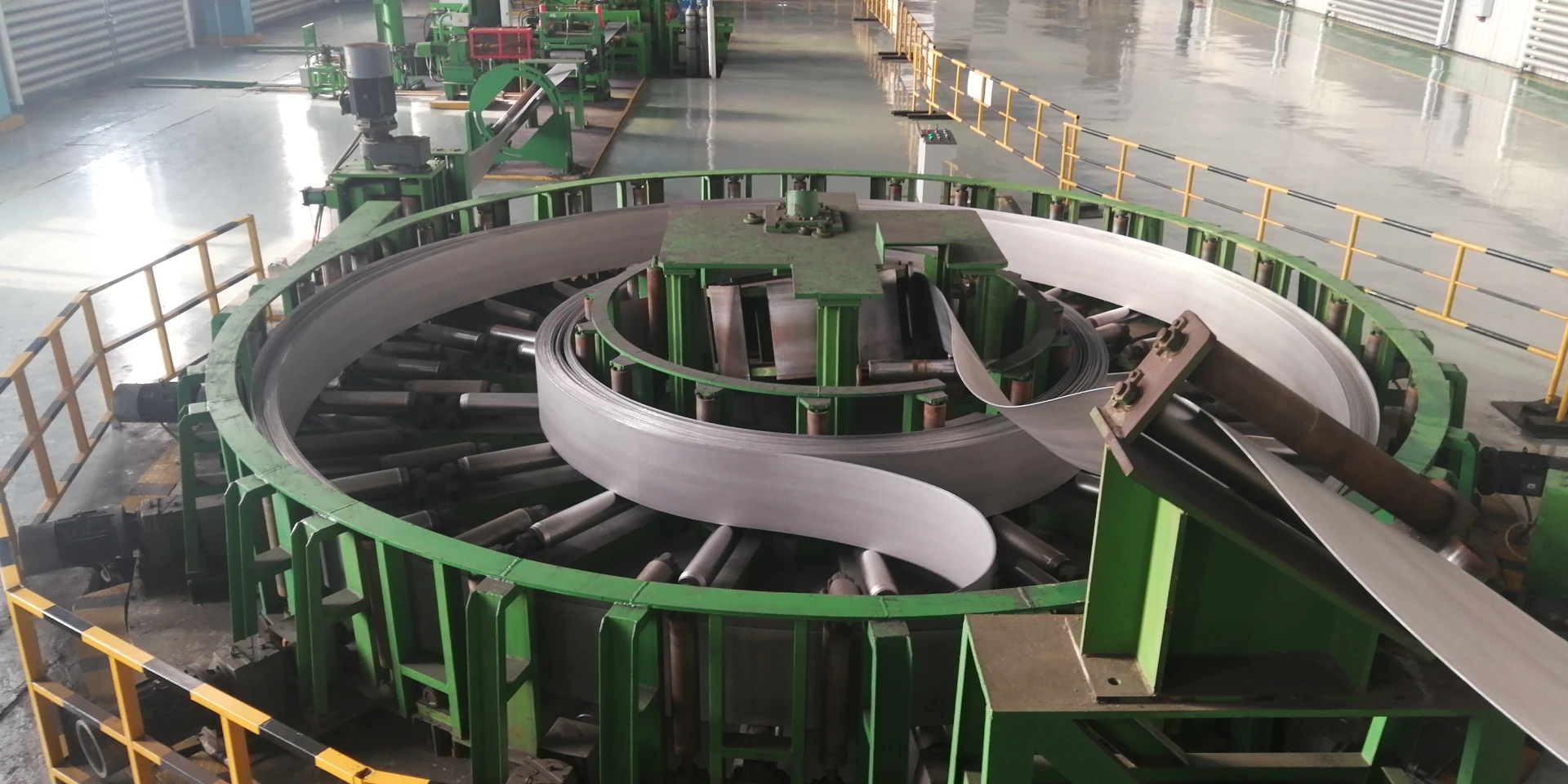

Walzwerkfertigung, or rolling mill production, stands as a cornerstone in the manufacturing industry, critical for producing sheet metal, metal foil, and other rolled materials essential in various applications. The intricacies of this production process combine traditional techniques with state-of-the-art technology, making it indispensable yet demanding a great degree of expertise and precision.

Trustworthiness in the walzwerkfertigung industry is earned through consistent quality and dependable output. Manufacturers often seek ISO certification and other quality management endorsements to solidify their standing in the global market. Industry leaders often invest in research and development to innovate rolling techniques, bringing improvements to traditional practices and integrating them with cutting-edge technology to maintain competitive integrity. A salient experience factor in walzwerkfertigung is the seamless integration of sustainability into production practices. As industries worldwide move towards greener manufacturing processes, rolling mills have adopted measures to reduce energy consumption and improve resource efficiency. Techniques such as heat recovery systems, closed-loop coolant systems, and advanced waste management protocols exemplify the rolling sector's commitment to environmental responsibility. For manufacturers looking to enhance their production capabilities through walzwerkfertigung, collaboration with knowledgeable engineers and seasoned technicians is invaluable. This partnership ensures that production outputs align with market demands, while also adhering to stringent environmental and quality standards. In summation, walzwerkfertigung is not merely about the reduction and reshaping of metals; it embodies a sophisticated blend of tradition, expertise, and innovation. This synergy is what enables manufacturers to generate products that are integral to today’s industrial frameworks, ensuring quality, performance, and sustainability. The future of rolling mill production lies in its ability to adapt and grow, ensuring that it remains a pillar of modern manufacturing excellence.

Trustworthiness in the walzwerkfertigung industry is earned through consistent quality and dependable output. Manufacturers often seek ISO certification and other quality management endorsements to solidify their standing in the global market. Industry leaders often invest in research and development to innovate rolling techniques, bringing improvements to traditional practices and integrating them with cutting-edge technology to maintain competitive integrity. A salient experience factor in walzwerkfertigung is the seamless integration of sustainability into production practices. As industries worldwide move towards greener manufacturing processes, rolling mills have adopted measures to reduce energy consumption and improve resource efficiency. Techniques such as heat recovery systems, closed-loop coolant systems, and advanced waste management protocols exemplify the rolling sector's commitment to environmental responsibility. For manufacturers looking to enhance their production capabilities through walzwerkfertigung, collaboration with knowledgeable engineers and seasoned technicians is invaluable. This partnership ensures that production outputs align with market demands, while also adhering to stringent environmental and quality standards. In summation, walzwerkfertigung is not merely about the reduction and reshaping of metals; it embodies a sophisticated blend of tradition, expertise, and innovation. This synergy is what enables manufacturers to generate products that are integral to today’s industrial frameworks, ensuring quality, performance, and sustainability. The future of rolling mill production lies in its ability to adapt and grow, ensuring that it remains a pillar of modern manufacturing excellence.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products