vierwalzenwalzwerk

Feb . 12, 2025 18:36

Back to list

vierwalzenwalzwerk

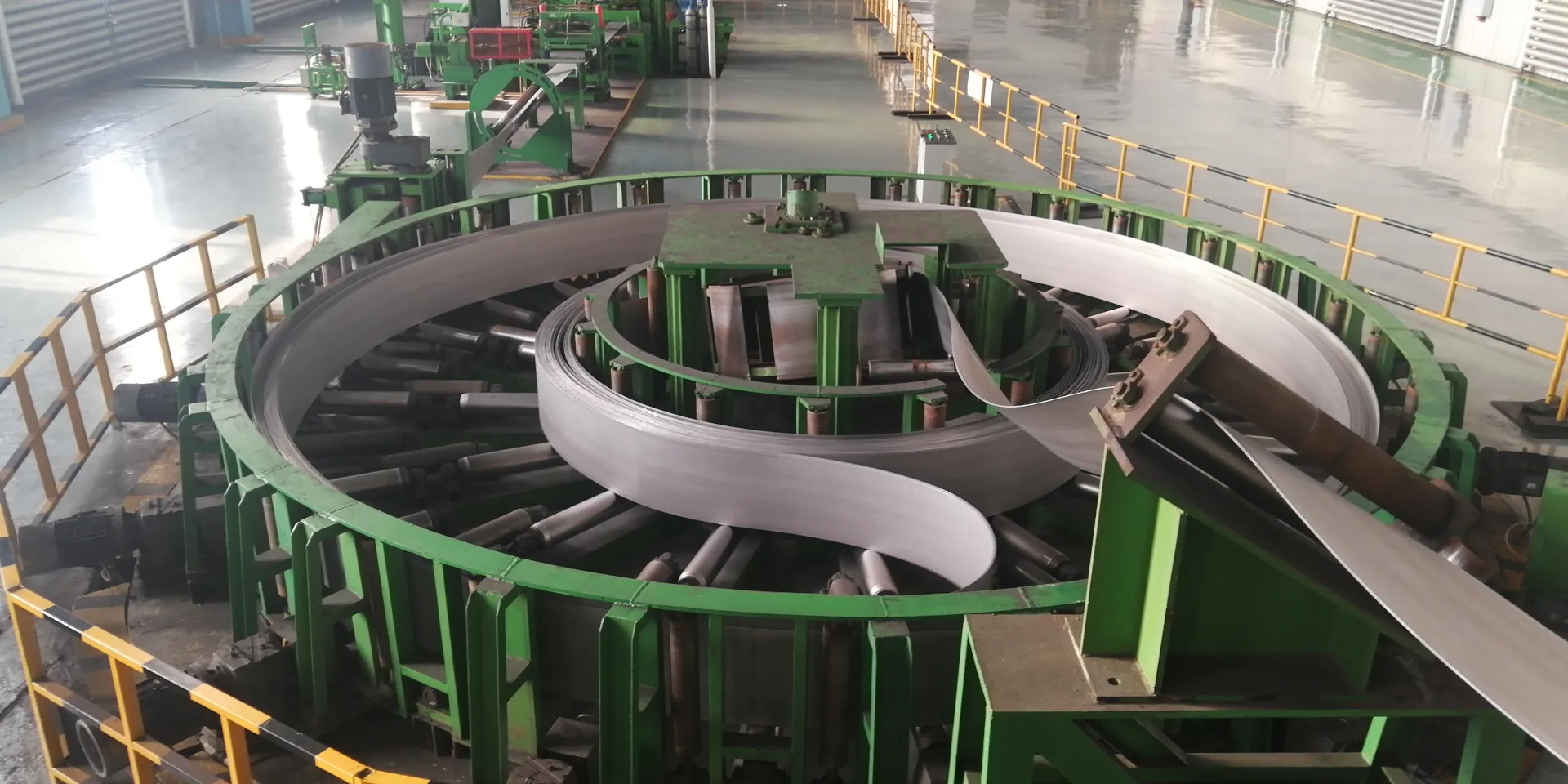

The advent of industrialization has seen the evolution of numerous manufacturing technologies. Among these, the four-high rolling mill, also known in German as Vierwalzenwalzwerk, has emerged as a pivotal innovation, driving advancements across various industrial sectors. Let's delve into its intricacies, benefits, and its influence on modern industries.

The authoritative aspect of Vierwalzenwalzwerk lies in its long-standing history and continued relevance. Introduced in the early 20th century, it has been continuously improved to integrate modern engineering techniques, thus maintaining its essential role in manufacturing. Companies investing in the latest four-high mills are often industry leaders, pushing technological boundaries and setting benchmarks for manufacturing excellence. Insights from these industry leaders form a definitive guide for others looking to optimize their production lines. Trustworthiness associated with Vierwalzenwalzwerk is evident from its widespread adoption. Industries dependent on precise metal shaping, such as electronics, construction, and transportation, rely heavily on the uniformity and reliability offered by these mills. Testimonials from industry professionals highlight how the precision of the four-high mill has become synonymous with operational excellence, translating into enhanced product durability and customer satisfaction. In summary, Vierwalzenwalzwerk holds a unique position in modern industry. Its ability to transform raw metal into high-quality products is backed by years of innovation and continuous improvement. The combination of experience, expertise, authoritative practices, and the trust it commands in the manufacturing sector solidifies its role as an essential component of industrial progress. Embracing this technology not only supports efficient production but also aligns with sustainable practices—a crucial consideration for industries aiming to thrive in the future.

The authoritative aspect of Vierwalzenwalzwerk lies in its long-standing history and continued relevance. Introduced in the early 20th century, it has been continuously improved to integrate modern engineering techniques, thus maintaining its essential role in manufacturing. Companies investing in the latest four-high mills are often industry leaders, pushing technological boundaries and setting benchmarks for manufacturing excellence. Insights from these industry leaders form a definitive guide for others looking to optimize their production lines. Trustworthiness associated with Vierwalzenwalzwerk is evident from its widespread adoption. Industries dependent on precise metal shaping, such as electronics, construction, and transportation, rely heavily on the uniformity and reliability offered by these mills. Testimonials from industry professionals highlight how the precision of the four-high mill has become synonymous with operational excellence, translating into enhanced product durability and customer satisfaction. In summary, Vierwalzenwalzwerk holds a unique position in modern industry. Its ability to transform raw metal into high-quality products is backed by years of innovation and continuous improvement. The combination of experience, expertise, authoritative practices, and the trust it commands in the manufacturing sector solidifies its role as an essential component of industrial progress. Embracing this technology not only supports efficient production but also aligns with sustainable practices—a crucial consideration for industries aiming to thrive in the future.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products