The Growing Role of Skin Pass Technology in Automotive Steel Manufacturing

The automotive industry demands steel with exceptional surface quality, precise mechanical properties, and consistent formability. To meet these stringent requirements, manufacturers rely on skin pass rolling, a critical finishing process that enhances the final characteristics of steel sheets before they are stamped into automotive components. A skin pass mill applies a minimal reduction (typically 0.5% to 3%) to the steel strip, improving its surface texture, flatness, and mechanical properties without significantly altering its thickness.

With the increasing demand for lightweight, high-strength automotive steels, 4 hi skin pass mills and hot skin pass mill systems have become indispensable in steel processing lines. This article explores the expanding role of skin pass technology in automotive steel manufacturing, focusing on its benefits, operational advancements, and future trends.

The Function and Importance of Skin Pass Rolling in Automotive Steel

Skin pass rolling serves multiple essential functions in automotive steel production:

Surface Texture Refinement – The process imparts a controlled roughness to the steel surface, ensuring optimal paint adhesion and corrosion resistance—critical for automotive body panels.

Yield Strength Adjustment – By applying slight cold work, a skin pass mill modifies the steel’s yield point, reducing the risk of Lüders bands (stretcher strains) that can mar the appearance of formed parts.

Improved Flatness and Dimensional Stability – The light rolling pass eliminates residual stresses, preventing warping during subsequent stamping operations.

Work Hardening Control – For advanced high-strength steels (AHSS), skin pass rolling fine-tunes ductility and springback behavior, ensuring consistent performance in crash-relevant components.

Automakers increasingly demand steel with these enhanced properties, making skin pass rolling a non-negotiable step in modern production lines.

Evolution of Skin Pass Mill Configurations: From Conventional to Advanced Systems

Early skin pass mills were relatively simple, but today’s automotive-grade steel requires more sophisticated setups. The most common configurations include:

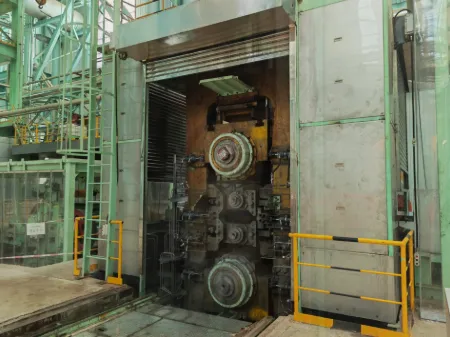

4 Hi Skin Pass Mill: Precision for High-Strength Steels

A 4 hi skin pass mill, featuring two work rolls and two backup rolls, provides superior control over roll deflection and strip flatness. This design is particularly effective for processing advanced high-strength steels (AHSS) and ultra-high-strength steels (UHSS), where even minor thickness deviations can affect stamping performance. The backup rolls minimize work roll bending, ensuring uniform pressure distribution across the strip width.

Hot Skin Pass Mill: Enhancing Coated Steels

For galvanized and other coated automotive steels, a hot skin pass mill operates at elevated temperatures to improve surface finish without damaging the coating. This variant is crucial for ensuring that zinc or aluminum-silicon coatings remain intact while still achieving the desired mechanical properties.

Modern skin pass mills also incorporate closed-loop control systems, leveraging real-time thickness gauges and shape sensors to dynamically adjust rolling parameters, further enhancing consistency.

Key Benefits of Skin Pass Technology in Automotive Applications

The automotive sector benefits significantly from optimized skin pass rolling processes:

Superior Paintability – A controlled surface texture ensures uniform paint application, reducing defects in exterior body panels.

Enhanced Formability – By eliminating yield point elongation, skin-passed steel forms smoothly in deep-drawing operations without surface defects.

Reduced Springback – High-strength steels exhibit less elastic recovery after stamping, improving dimensional accuracy in structural components.

Extended Tool Life – Smoother steel surfaces reduce wear on stamping dies, lowering maintenance costs for automakers.

These advantages make skin pass rolling indispensable for producing high-quality automotive steel.

Challenges and Innovations in Skin Pass Mill Operations

Despite its advantages, skin pass rolling presents several challenges that manufacturers must address:

Precision Thickness Control – Even minor over-reduction can compromise material properties, necessitating ultra-precise roll gap adjustments.

Roll Surface Degradation – The repeated light rolling passes can still cause work roll wear over time, requiring advanced roll maintenance strategies.

Energy Efficiency – While less energy-intensive than heavy rolling, optimizing power consumption remains a priority for sustainable production.

To overcome these challenges, manufacturers are adopting:

Laser-Textured Rolls – Providing consistent surface finishes and extending roll life.

AI-Based Process Optimization – Machine learning algorithms adjust rolling parameters in real time for maximum efficiency.

Hybrid Lubrication Systems – Reducing friction while maintaining surface quality.

Skin Pass Rolling as a Critical Enabler of Automotive Excellence

The skin pass mill is no longer just a finishing step—it is a vital technology that defines the quality, performance, and manufacturability of automotive steel. As vehicle designs demand lighter, stronger, and more formable materials, advancements in 4 hi skin pass mill and hot skin pass mill systems will play a pivotal role in meeting these needs.

By embracing automation, AI-driven optimization, and sustainable practices, steel manufacturers can ensure that their skin pass rolling processes continue to drive innovation in the automotive industry. The future of automotive steel depends on the precision and adaptability of this critical technology.

-

YWLX’s 1450mm Six-Hi Reversing Mill Goes Live in BangladeshNewsNov.24,2025

-

Adjusting Roll Gap in 6Hi Reversing Cold Rolling Mill for Thin StripNewsNov.13,2025

-

Quality Control Standards for Automatic Gauge Control in Strip RollingNewsNov.13,2025

-

Effect of Skin Pass Rolling on Metal DuctilityNewsNov.13,2025

-

Key Components of a Modern TempermillNewsNov.13,2025

-

Common Wear Patterns of Work Roll in Tandem Cold Mill OperationsNewsNov.13,2025

-

Revolutionary Skin Pass Rolling Technology for Enhanced Steel QualityNewsNov.04,2025