temper pass mill

Mar . 04, 2025 03:16

Back to list

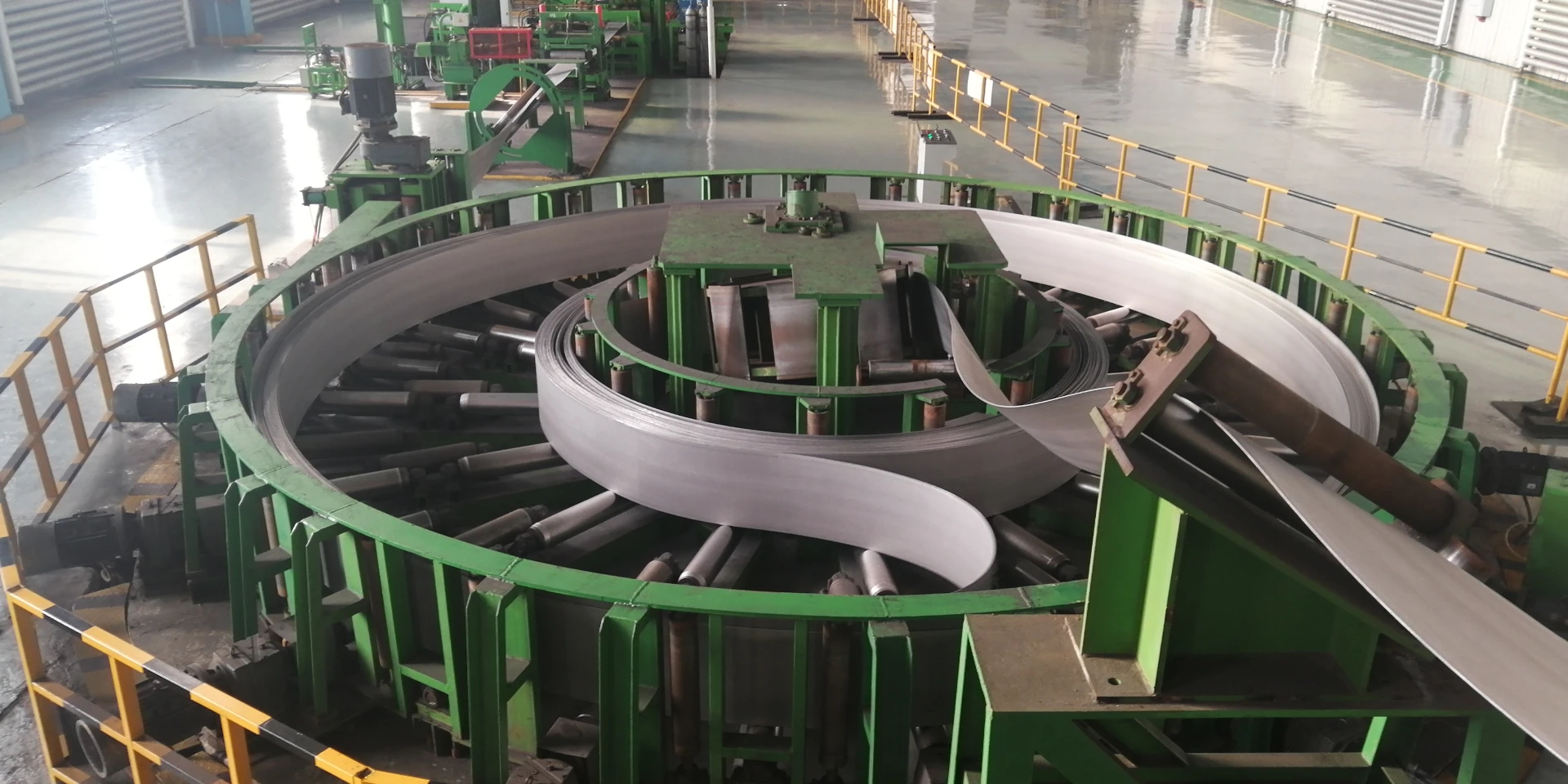

temper pass mill

Temper pass mills stand as critical components in the realm of metal processing, offering a nuanced method for enhancing the quality of metal sheets. These mills perform a light cold rolling process, crucial for improving the surface finish and mechanical properties of processed metals. Drawing from years of experience in industrial metal processing, this examination of temper pass mills delves into their operational intricacies, benefits, and technological advancements, establishing a comprehensive guide for industry professionals seeking to optimize manufacturing processes.

Trust in temper pass mill technology is further established by rigorous quality assurance practices adhered to by manufacturers. Regular calibration of the mill’s components, along with adherence to safety and environmental regulations, is essential in maintaining the integrity of the product and ensuring operational safety. By utilizing certified materials and components, manufacturers enhance the reliability of these mills, aligning them with global standards and reinforcing buyer confidence. Expanding on the product-specific benefits, temper pass mills not only enhance the mechanical properties and surface quality of metal sheets but also positively impact downstream processes. The improved flatness and surface finish contribute to reduced rejection rates during subsequent manufacturing phases such as stamping, drawing, or coating. Consequently, manufacturers observe not just a rise in product quality but also in manufacturing efficiency and cost-effectiveness. From the standpoint of technological sustainability, the future of temper pass mills is oriented towards greater energy efficiency and eco-friendly operation. Developments in drive systems and roll technologies, such as the implementation of hybrid and fully electric systems, contribute to reduced energy consumption and lower carbon footprints. These sustainable advancements align with broader industry goals of reducing environmental impact while simultaneously increasing operational efficiency. In conclusion, temper pass mills represent a cornerstone in metal processing, combining precise engineering with advanced technology to enhance product quality and manufacturing efficiency. By continually integrating emerging technologies and maintaining strict adherence to quality standards, temper pass mills will remain an indispensable tool in the metalworking industry, trusted by professionals around the globe.

Trust in temper pass mill technology is further established by rigorous quality assurance practices adhered to by manufacturers. Regular calibration of the mill’s components, along with adherence to safety and environmental regulations, is essential in maintaining the integrity of the product and ensuring operational safety. By utilizing certified materials and components, manufacturers enhance the reliability of these mills, aligning them with global standards and reinforcing buyer confidence. Expanding on the product-specific benefits, temper pass mills not only enhance the mechanical properties and surface quality of metal sheets but also positively impact downstream processes. The improved flatness and surface finish contribute to reduced rejection rates during subsequent manufacturing phases such as stamping, drawing, or coating. Consequently, manufacturers observe not just a rise in product quality but also in manufacturing efficiency and cost-effectiveness. From the standpoint of technological sustainability, the future of temper pass mills is oriented towards greater energy efficiency and eco-friendly operation. Developments in drive systems and roll technologies, such as the implementation of hybrid and fully electric systems, contribute to reduced energy consumption and lower carbon footprints. These sustainable advancements align with broader industry goals of reducing environmental impact while simultaneously increasing operational efficiency. In conclusion, temper pass mills represent a cornerstone in metal processing, combining precise engineering with advanced technology to enhance product quality and manufacturing efficiency. By continually integrating emerging technologies and maintaining strict adherence to quality standards, temper pass mills will remain an indispensable tool in the metalworking industry, trusted by professionals around the globe.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products