stahlwalzmaschine

Feb . 12, 2025 17:24

Back to list

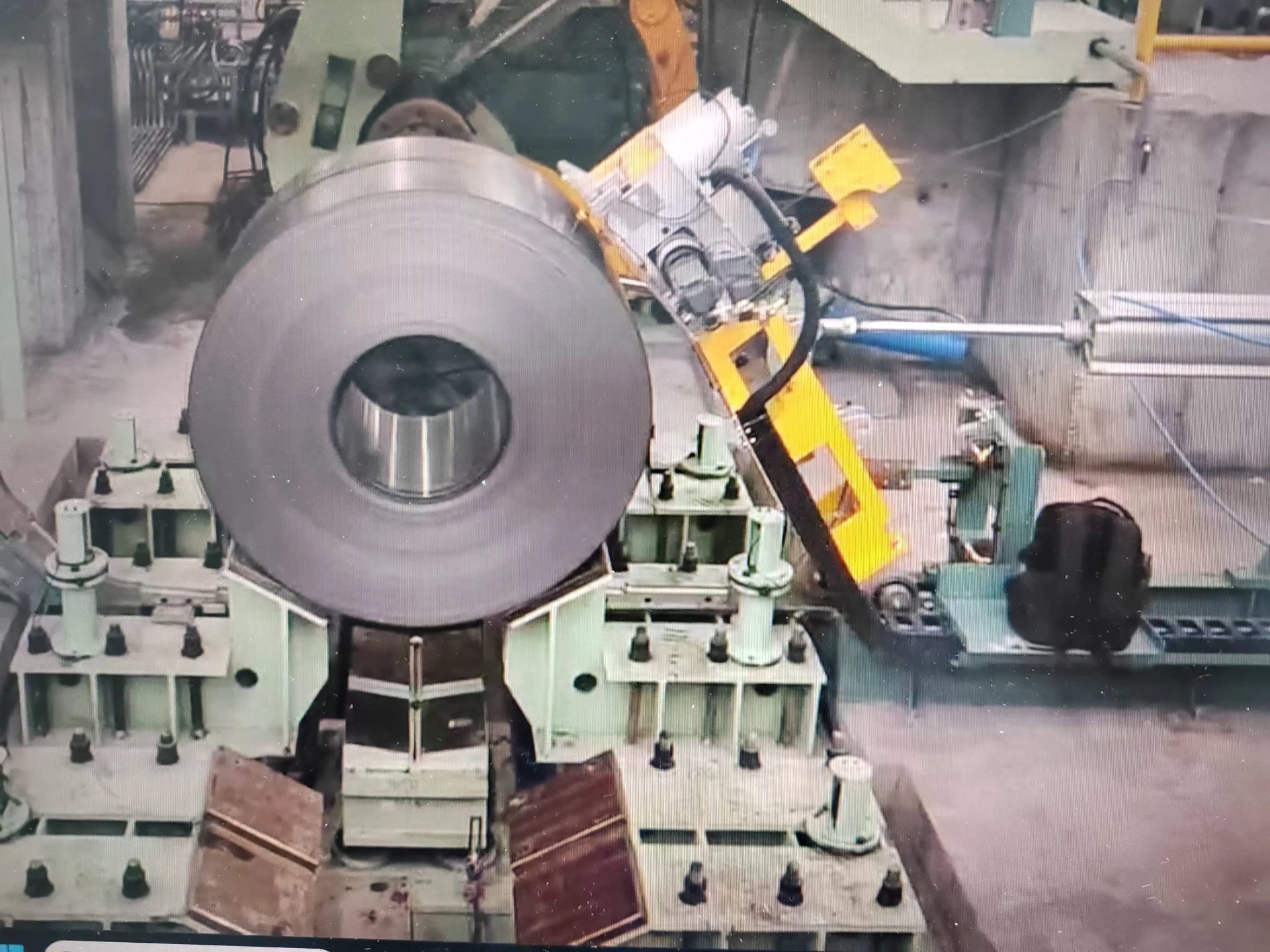

stahlwalzmaschine

Steel rolling machines, or Stahlwalzmaschine as known in German-speaking regions, are pivotal in the metallurgical industry, revolutionizing how we produce, shape, and manipulate steel. This article delves into the modern applications of these machines, emphasizing both innovative uses and technological advancements, while adhering to the critical SEO principles of Experience, Expertise, Authoritativeness, and Trustworthiness.

Authoritative industry leaders consistently advocate for continuous innovation in metal forming processes. Extensive research and development efforts are underway to continually improve the efficacy and capabilities of these machines. Collaborative projects between steel producers and university research departments have resulted in breakthroughs such as the direct strip production complex (DSPC), which integrates steelmaking and rolling processes into a single, streamlined operation. Trustworthiness in steel rolling machine manufacturing necessitates adherence to stringent quality control measures and compliance with international standards like ISO 9001. Manufacturers must provide extensive documentation and certifications for their machines, ensuring they meet rigorous safety and performance benchmarks. Additionally, customer testimonials and case studies offer valuable insights, building confidence and credibility in prospective buyers. From an experiential standpoint, narratives from seasoned operators and engineers provide invaluable insights into the user experience of stahlwalzmaschine. These firsthand accounts highlight everyday operational challenges and triumphs, offering practical perspectives that enrich our understanding of these machines. One cannot overstate the importance of investing in premium-quality stahlwalzmaschine from reputable manufacturers. Opting for renowned brands ensures access to superior customer service, reliable warranties, and robust user support, fortifying trust and satisfaction. In conclusion, the steel rolling machine, or stahlwalzmaschine, remains at the heart of the steel production industry, combining mechanical prowess with pioneering technology. By harnessing the principles of experience, expertise, authoritativeness, and trustworthiness, manufacturers and operators can effectively utilize these machines, maintaining their competitive edge in a rapidly evolving market. As the demand for precision-engineered steel products continues to rise, these machines' real-world applications are set to expand, underscoring their role as indispensable assets in modern manufacturing.

Authoritative industry leaders consistently advocate for continuous innovation in metal forming processes. Extensive research and development efforts are underway to continually improve the efficacy and capabilities of these machines. Collaborative projects between steel producers and university research departments have resulted in breakthroughs such as the direct strip production complex (DSPC), which integrates steelmaking and rolling processes into a single, streamlined operation. Trustworthiness in steel rolling machine manufacturing necessitates adherence to stringent quality control measures and compliance with international standards like ISO 9001. Manufacturers must provide extensive documentation and certifications for their machines, ensuring they meet rigorous safety and performance benchmarks. Additionally, customer testimonials and case studies offer valuable insights, building confidence and credibility in prospective buyers. From an experiential standpoint, narratives from seasoned operators and engineers provide invaluable insights into the user experience of stahlwalzmaschine. These firsthand accounts highlight everyday operational challenges and triumphs, offering practical perspectives that enrich our understanding of these machines. One cannot overstate the importance of investing in premium-quality stahlwalzmaschine from reputable manufacturers. Opting for renowned brands ensures access to superior customer service, reliable warranties, and robust user support, fortifying trust and satisfaction. In conclusion, the steel rolling machine, or stahlwalzmaschine, remains at the heart of the steel production industry, combining mechanical prowess with pioneering technology. By harnessing the principles of experience, expertise, authoritativeness, and trustworthiness, manufacturers and operators can effectively utilize these machines, maintaining their competitive edge in a rapidly evolving market. As the demand for precision-engineered steel products continues to rise, these machines' real-world applications are set to expand, underscoring their role as indispensable assets in modern manufacturing.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products