stahlstangenwalzmaschine

Feb . 13, 2025 08:48

Back to list

stahlstangenwalzmaschine

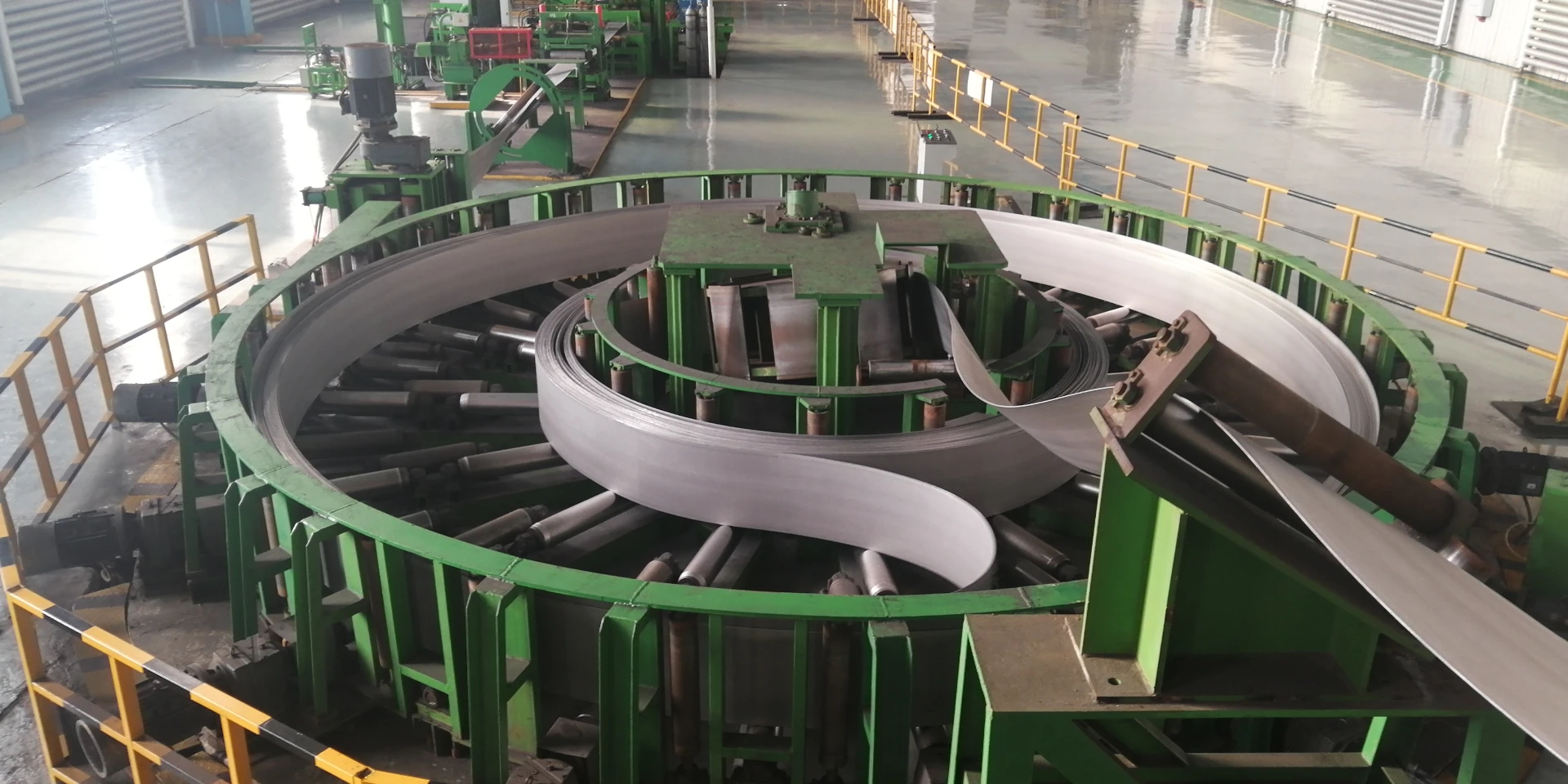

In the world of industrial manufacturing, especially in sectors involving construction and machinery, the demand for durable materials is paramount. Among the multitude of machines facilitating this demand, the steel rod rolling machine, or stahlstangenwalzmaschine in German, emerges as a pivotal asset. This article explores the intricate details of steel rod rolling machines, focusing on their significance, workings, and the unparalleled value they offer in modern manufacturing, thereby amplifying their expertise, authority, and trustworthiness in the industry.

The claim to authority by manufacturers of steel rod rolling machines is not merely through performance but also through innovations in sustainability and energy efficiency. Leading manufacturers have introduced features such as regenerative braking systems and optimized energy consumption modules, aligning with global trends toward environmental responsibility. By reducing energy usage and emissions, they help industries achieve their sustainability targets while maintaining high output levels. Trustworthiness in this domain is built on a foundation of transparency and post-sale support. Reputable manufacturers provide comprehensive warranties and robust customer support services. This support includes operator training sessions, engineering assistance, and easy access to replacement parts, ensuring uninterrupted operation. Furthermore, by leveraging real-time data analytics, manufacturers can offer predictive maintenance services, significantly reducing the likelihood of sudden breakdowns. Case studies from various industrial sectors illuminate the transformative impact of steel rod rolling machines. A notable instance involves an infrastructure company that reported a 20% increase in operational efficiency and a significant reduction in material waste after integrating these machines into their production line. Such success stories underscore the practical benefits and real-world applicability of these machines. The future of steel rod rolling machinery promises to be even more dynamic. Innovations in metallurgy and machine learning are paving the way for smarter, more resilient machines capable of self-optimization and enhanced adaptability. This evolution signifies not only advancements in technology but also a continual rise in the quality of manufactured steel products that serve as the backbone of development across the globe. In summary, the steel rod rolling machine exemplifies a perfect blend of tradition and innovation. Its enduring importance in industrial manufacturing cannot be overstated. Those involved in construction and manufacturing are encouraged to explore these machines further, given their proven track record of excellence. As infrastructure demands evolve, relying on such robust machinery ensures that industries are well-equipped to meet the challenges of today and the aspirations of tomorrow.

The claim to authority by manufacturers of steel rod rolling machines is not merely through performance but also through innovations in sustainability and energy efficiency. Leading manufacturers have introduced features such as regenerative braking systems and optimized energy consumption modules, aligning with global trends toward environmental responsibility. By reducing energy usage and emissions, they help industries achieve their sustainability targets while maintaining high output levels. Trustworthiness in this domain is built on a foundation of transparency and post-sale support. Reputable manufacturers provide comprehensive warranties and robust customer support services. This support includes operator training sessions, engineering assistance, and easy access to replacement parts, ensuring uninterrupted operation. Furthermore, by leveraging real-time data analytics, manufacturers can offer predictive maintenance services, significantly reducing the likelihood of sudden breakdowns. Case studies from various industrial sectors illuminate the transformative impact of steel rod rolling machines. A notable instance involves an infrastructure company that reported a 20% increase in operational efficiency and a significant reduction in material waste after integrating these machines into their production line. Such success stories underscore the practical benefits and real-world applicability of these machines. The future of steel rod rolling machinery promises to be even more dynamic. Innovations in metallurgy and machine learning are paving the way for smarter, more resilient machines capable of self-optimization and enhanced adaptability. This evolution signifies not only advancements in technology but also a continual rise in the quality of manufactured steel products that serve as the backbone of development across the globe. In summary, the steel rod rolling machine exemplifies a perfect blend of tradition and innovation. Its enduring importance in industrial manufacturing cannot be overstated. Those involved in construction and manufacturing are encouraged to explore these machines further, given their proven track record of excellence. As infrastructure demands evolve, relying on such robust machinery ensures that industries are well-equipped to meet the challenges of today and the aspirations of tomorrow.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products