skin pass mill process pdf

Feb . 16, 2025 05:19

Back to list

skin pass mill process pdf

The skin pass mill process is a crucial step in the steel manufacturing industry, captivating industries around the globe seeking to enhance surface quality and mechanical properties of steel strips. This process is predominantly employed to improve the finish of cold-rolled steel and impart desirable surface characteristics that meet the stringent demands of downstream processes, making it indispensable for a myriad of applications.

Achieving the pinnacle of quality and consistency in the skin pass mill process translates into the employment of innovative technologies and adherence to established industry standards. Companies renowned in the steel manufacturing sector invest significantly in R&D initiatives to enhance the capability of their skin pass mills. This continuous evolution in technology facilitates the development of sustainable practices, reducing energy consumption and minimizing material waste. Additionally, collaboration with metallurgical experts and reliance on cutting-edge quality control systems empowers producers to troubleshoot potential issues swiftly and effectively—ensuring uninterrupted production and superior product quality. Trust and credibility are further cemented by complying with international standards, thereby assuring customers of the reliability and durability of their steel products. Stakeholders across various industries place immense trust in suppliers demonstrating a solid commitment to environment-friendly practices and product excellence. Skin pass mills contribute to this commitment by ensuring the efficient use of recycled materials and optimizing processes to minimize environmental impact. The authoritative stance that established manufacturers maintain involves a shared responsibility in promoting sustainability across the industry. In summary, the skin pass mill process is a definitive factor of success for steel manufacturers seeking a balance between productivity and quality. Its influence on product integrity, coupled with the technical prowess required to operate these complex machines, underscores its relevancy in meeting challenging industrial demands. The integration of contemporary technologies and strategic process improvements fortify the industry’s dedication to providing exceptional steel products that cater to the ever-evolving market landscape, reinforcing a legacy of trust and authority within the global steel community.

Achieving the pinnacle of quality and consistency in the skin pass mill process translates into the employment of innovative technologies and adherence to established industry standards. Companies renowned in the steel manufacturing sector invest significantly in R&D initiatives to enhance the capability of their skin pass mills. This continuous evolution in technology facilitates the development of sustainable practices, reducing energy consumption and minimizing material waste. Additionally, collaboration with metallurgical experts and reliance on cutting-edge quality control systems empowers producers to troubleshoot potential issues swiftly and effectively—ensuring uninterrupted production and superior product quality. Trust and credibility are further cemented by complying with international standards, thereby assuring customers of the reliability and durability of their steel products. Stakeholders across various industries place immense trust in suppliers demonstrating a solid commitment to environment-friendly practices and product excellence. Skin pass mills contribute to this commitment by ensuring the efficient use of recycled materials and optimizing processes to minimize environmental impact. The authoritative stance that established manufacturers maintain involves a shared responsibility in promoting sustainability across the industry. In summary, the skin pass mill process is a definitive factor of success for steel manufacturers seeking a balance between productivity and quality. Its influence on product integrity, coupled with the technical prowess required to operate these complex machines, underscores its relevancy in meeting challenging industrial demands. The integration of contemporary technologies and strategic process improvements fortify the industry’s dedication to providing exceptional steel products that cater to the ever-evolving market landscape, reinforcing a legacy of trust and authority within the global steel community.

Latest news

-

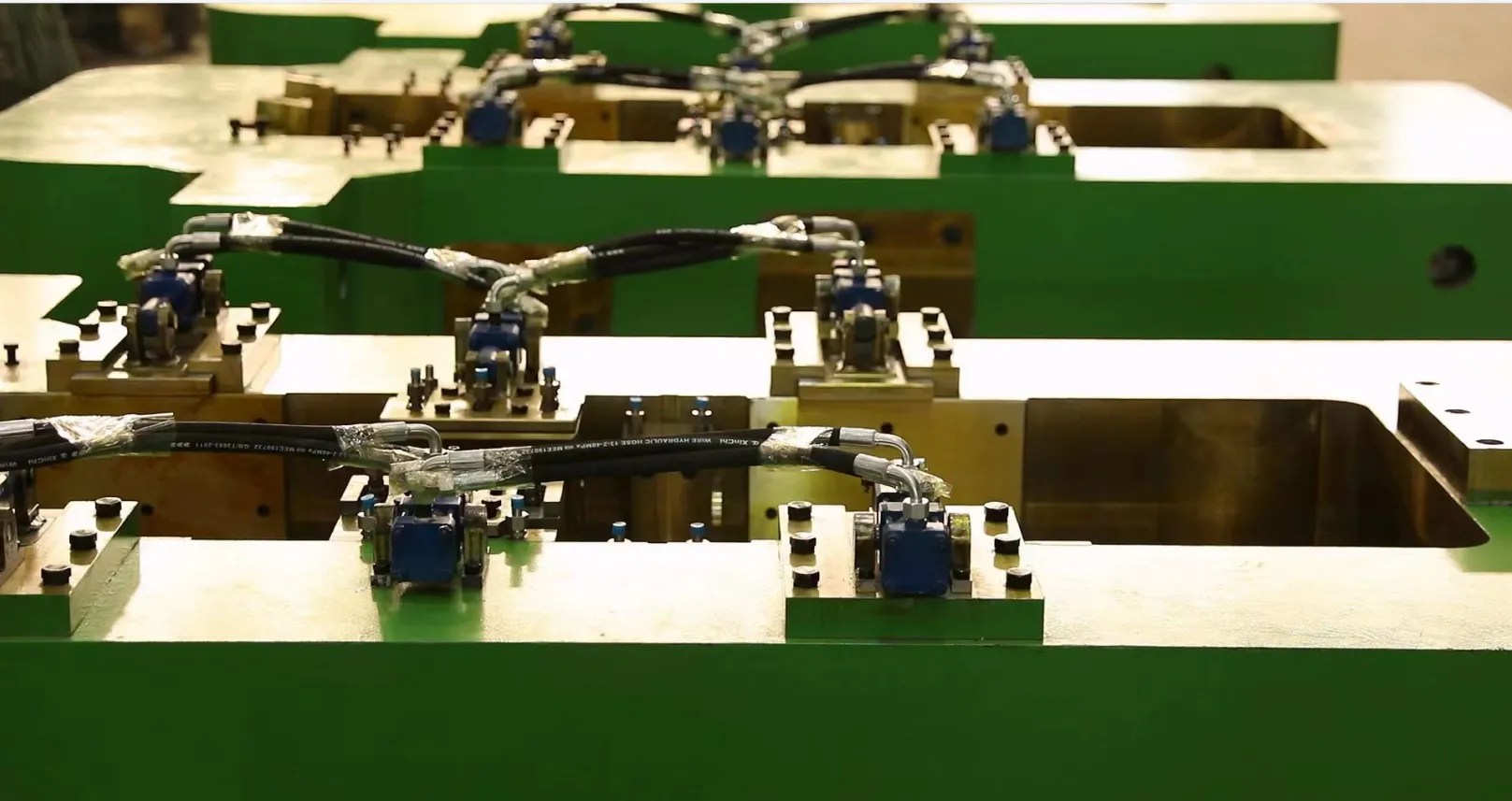

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products