skin pass mill function

Feb . 16, 2025 04:45

Back to list

skin pass mill function

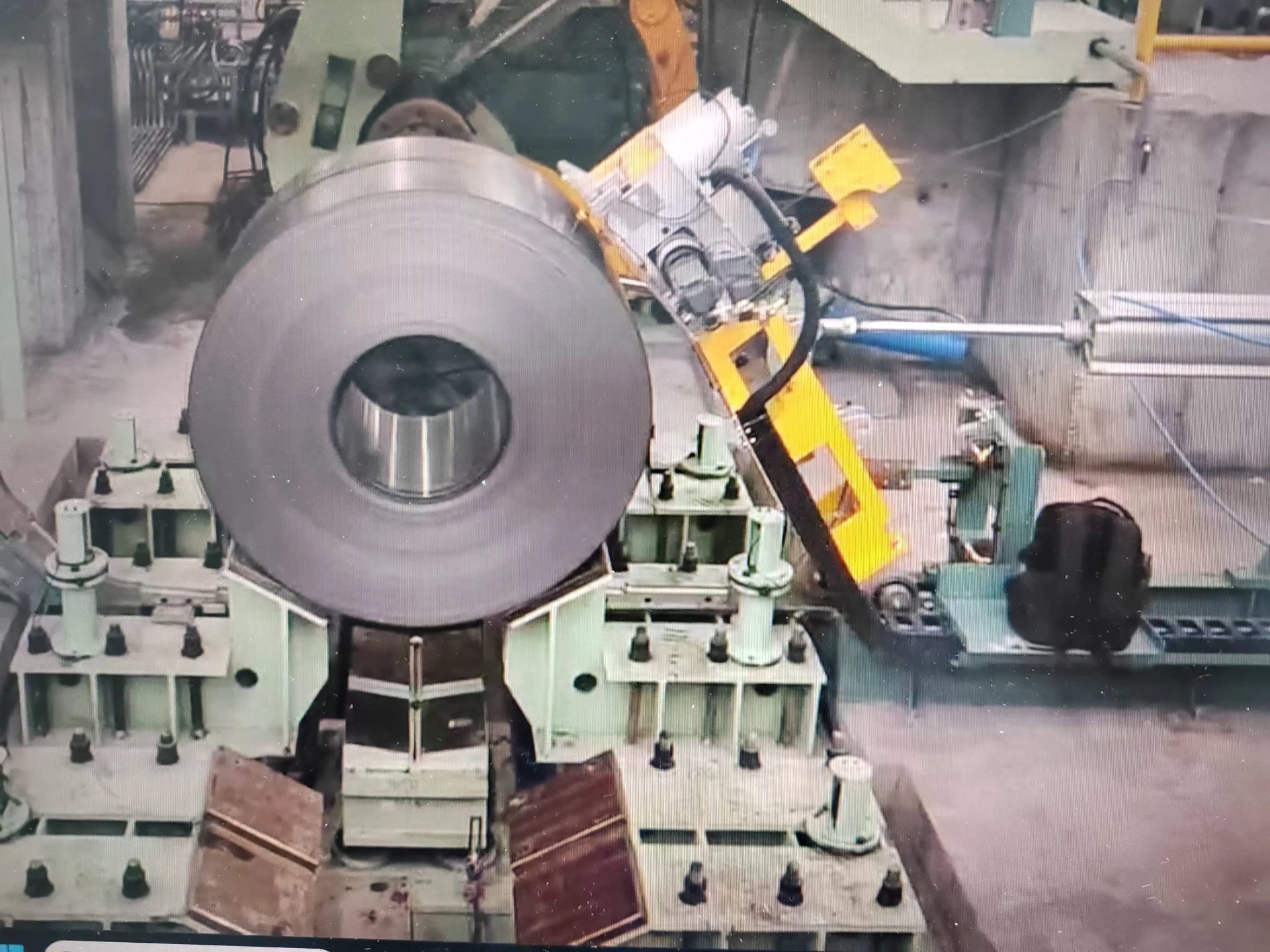

In the dynamic and precision-driven field of metal manufacturing, the skin pass mill plays a crucial role in enhancing both the aesthetic and functional quality of metal sheets. An essential component of any high-end rolling facility, the skin pass mill is designed to provide the final touch that can significantly affect the performance of the metal in its intended application.

Environmental considerations also play a significant role in the operation of skin pass mills. Modern designs incorporate eco-friendly technologies that significantly reduce energy consumption and lower emissions. By optimizing power usage, these machines contribute to a more sustainable production process, aligning with industry trends that prioritize eco-conscious manufacturing. The expertise required to operate and maintain a skin pass mill cannot be overstated. Skilled technicians oversee the complex processes and make adjustments based on real-time data to ensure optimal machine performance. Their expertise is crucial in troubleshooting issues and implementing corrective actions that prevent product deficiencies, thereby upholding the manufacturer's reputation for quality and reliability. Trustworthiness in utilizing skin pass mills is guaranteed by adherence to industry standards and rigorous quality control measures. Stringent protocols are in place to ensure that every output meets predefined criteria before it is approved for shipment. Partnerships with leading technological firms further enhance the trust component by integrating the latest innovations in metal processing. The authoritative nature of the skin pass mill’s function is emphasized by its critical role in the supply chain. For industries such as automotive, construction, and consumer goods, the quality of the metal provided impacts everything from product safety to customer satisfaction. Companies leveraging state-of-the-art skin pass mills position themselves as leaders in delivering top-tier products that meet the highest industry standards. In summary, the skin pass mill is a sophisticated equipment central to producing flat, smooth, and mechanically optimized metal sheets. Its function goes beyond basic material processing, contributing to the overall efficiency, quality, and environmental stewardship of a manufacturing operation. The successful implementation of skin pass mills speaks to a company’s commitment to superior manufacturing practices, shaping their reputation as a trusted provider of high-quality metal products.

Environmental considerations also play a significant role in the operation of skin pass mills. Modern designs incorporate eco-friendly technologies that significantly reduce energy consumption and lower emissions. By optimizing power usage, these machines contribute to a more sustainable production process, aligning with industry trends that prioritize eco-conscious manufacturing. The expertise required to operate and maintain a skin pass mill cannot be overstated. Skilled technicians oversee the complex processes and make adjustments based on real-time data to ensure optimal machine performance. Their expertise is crucial in troubleshooting issues and implementing corrective actions that prevent product deficiencies, thereby upholding the manufacturer's reputation for quality and reliability. Trustworthiness in utilizing skin pass mills is guaranteed by adherence to industry standards and rigorous quality control measures. Stringent protocols are in place to ensure that every output meets predefined criteria before it is approved for shipment. Partnerships with leading technological firms further enhance the trust component by integrating the latest innovations in metal processing. The authoritative nature of the skin pass mill’s function is emphasized by its critical role in the supply chain. For industries such as automotive, construction, and consumer goods, the quality of the metal provided impacts everything from product safety to customer satisfaction. Companies leveraging state-of-the-art skin pass mills position themselves as leaders in delivering top-tier products that meet the highest industry standards. In summary, the skin pass mill is a sophisticated equipment central to producing flat, smooth, and mechanically optimized metal sheets. Its function goes beyond basic material processing, contributing to the overall efficiency, quality, and environmental stewardship of a manufacturing operation. The successful implementation of skin pass mills speaks to a company’s commitment to superior manufacturing practices, shaping their reputation as a trusted provider of high-quality metal products.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products