skinpass mill

Feb . 16, 2025 04:28

Back to list

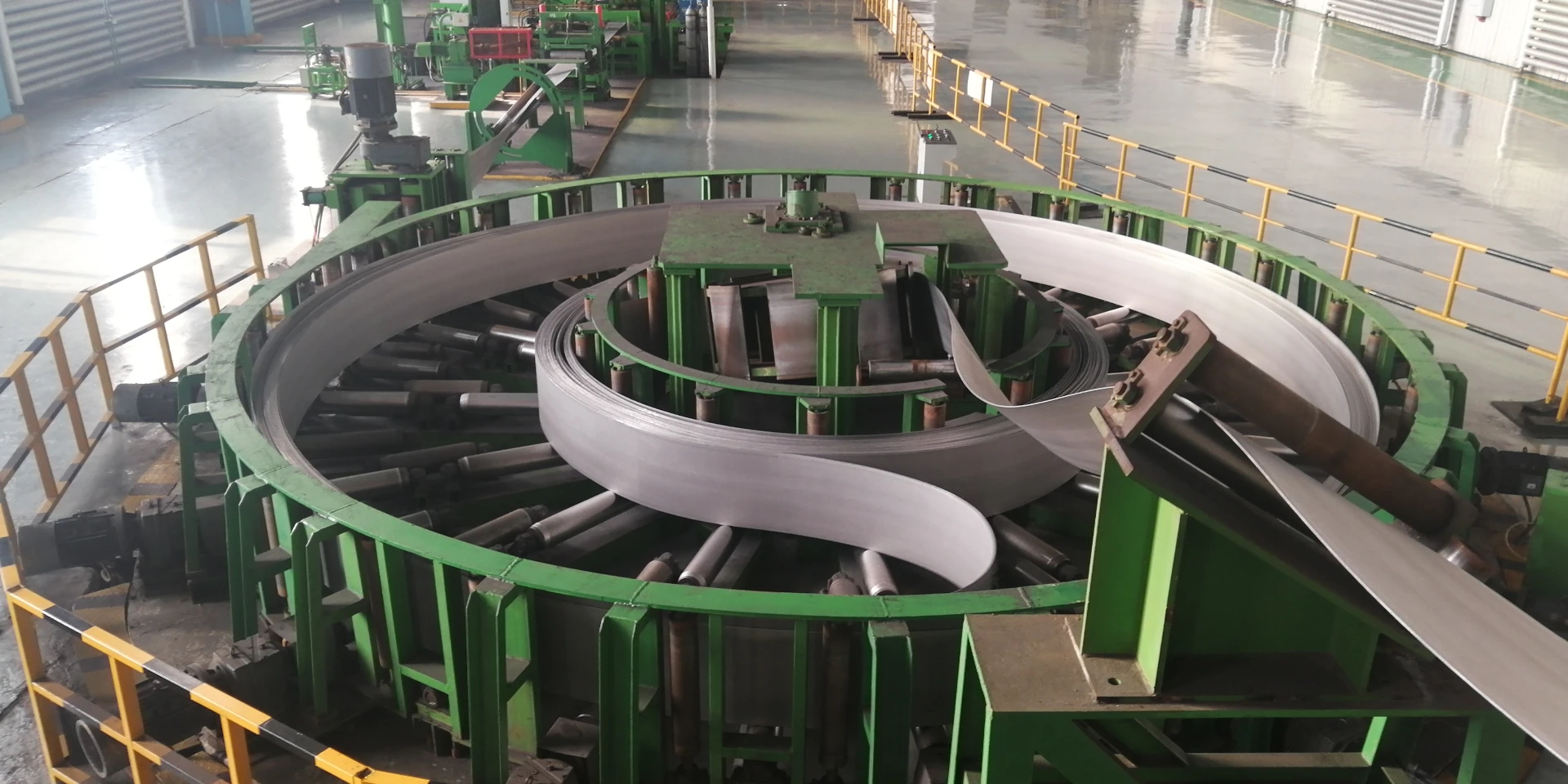

skinpass mill

Skinpass mills, an essential component of the steel processing industry, play a crucial role in producing high-quality finished products. The primary function of these mills is to enhance surface quality and mechanical properties of the steel, offering benefits such as improved flatness, reduced yield point elongation, and enhanced surface texture. The process, known as skin passing or temper rolling, involves a light cold rolling with a small reduction in thickness, which significantly upgrades the final product quality.

Trustworthiness in the deployment of skinpass mills is further evidenced by the integration of state-of-the-art automation and control systems. These systems are designed to provide real-time monitoring and feedback, fostering a reliable and consistent production environment. Operators with industry-certified training and experience can harness these technologies to reduce human error and enhance the overall efficiency of the rolling process. Moreover, the adoption of environmentally-friendly practices within the operation of skinpass mills emphasizes a commitment to sustainable manufacturing. This includes the judicious use of energy and materials, as well as the implementation of recycling strategies for mill waste products. Leading steel producers prioritize sustainability in their operations, thereby building trust with environmentally-conscious consumers and stakeholders. In conclusion, skinpass mills are indispensable in producing high-grade steel with superior surface qualities. Proficiency in material selection, operational execution, quality assurance, and sustainable practices contribute to the elevated stature of these mills within the steel industry. Companies leveraging advanced technologies and experienced operators can establish themselves as leaders in the market, delivering consistently excellent products tailored to the exacting demands of diverse industries. As the industry evolves, these mills will continue to be at the forefront, empowering manufacturers to meet new challenges with innovation and reliability.

Trustworthiness in the deployment of skinpass mills is further evidenced by the integration of state-of-the-art automation and control systems. These systems are designed to provide real-time monitoring and feedback, fostering a reliable and consistent production environment. Operators with industry-certified training and experience can harness these technologies to reduce human error and enhance the overall efficiency of the rolling process. Moreover, the adoption of environmentally-friendly practices within the operation of skinpass mills emphasizes a commitment to sustainable manufacturing. This includes the judicious use of energy and materials, as well as the implementation of recycling strategies for mill waste products. Leading steel producers prioritize sustainability in their operations, thereby building trust with environmentally-conscious consumers and stakeholders. In conclusion, skinpass mills are indispensable in producing high-grade steel with superior surface qualities. Proficiency in material selection, operational execution, quality assurance, and sustainable practices contribute to the elevated stature of these mills within the steel industry. Companies leveraging advanced technologies and experienced operators can establish themselves as leaders in the market, delivering consistently excellent products tailored to the exacting demands of diverse industries. As the industry evolves, these mills will continue to be at the forefront, empowering manufacturers to meet new challenges with innovation and reliability.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products