sheet metal rolling mill

Jan . 14, 2025 12:26

Back to list

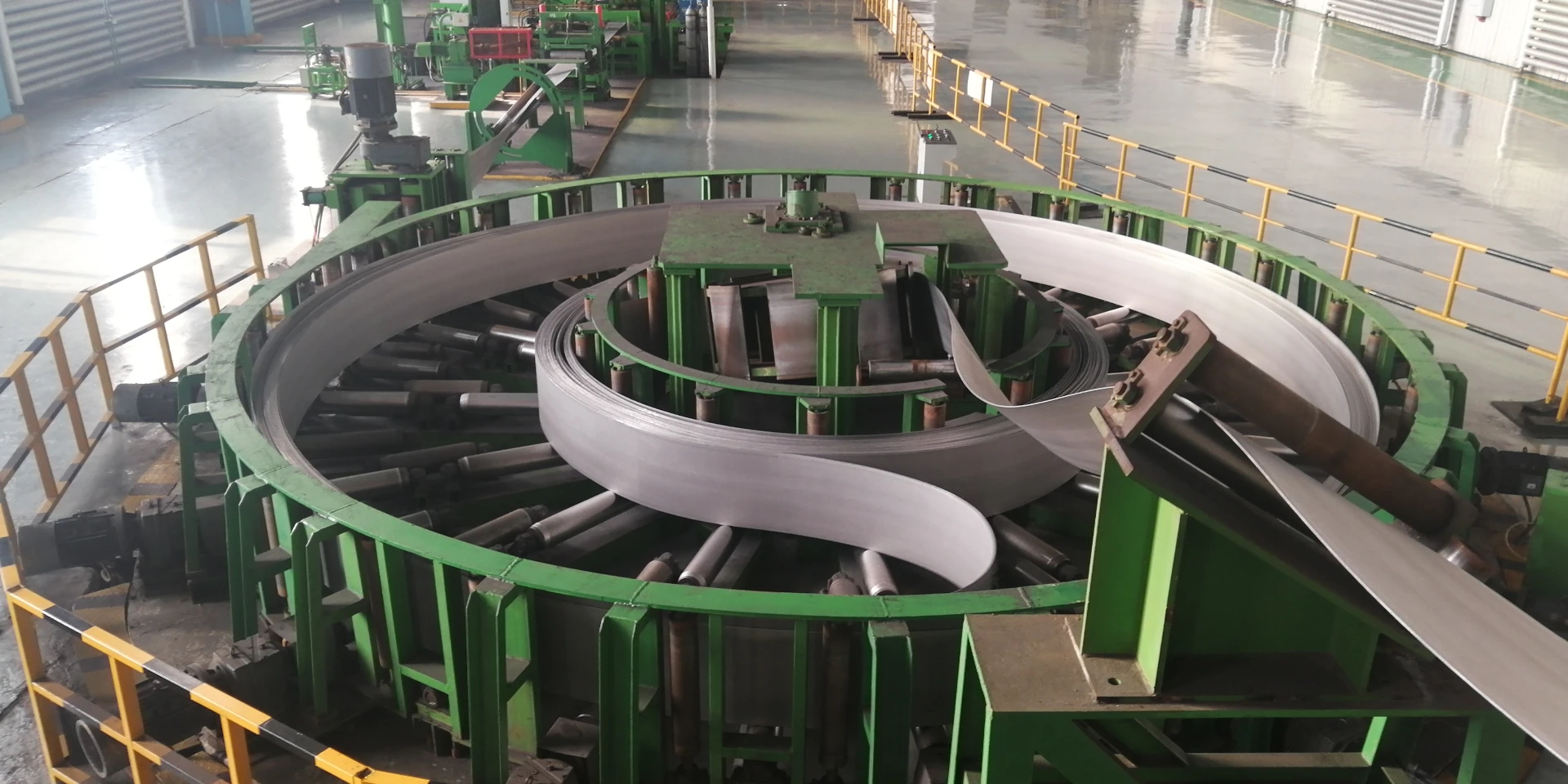

sheet metal rolling mill

Sheet metal rolling mills have been the backbone of the industrial manufacturing sector, shaping the landscape of modern architectural developments and machinery. The cutting-edge technology and engineering precision inherent in these mills have made them indispensable in the production of high-quality metal sheets used worldwide.

The expertise involved in running a sheet metal rolling mill extends beyond mechanical proficiency. Operators must be knowledgeable about material science to make informed decisions about metal types, as different metals react uniquely under pressure and temperature variations. This understanding directly impacts the product's quality, necessitating continual education and training to keep abreast of industry advancements. When it comes to showcasing authority in the sheet metal rolling mill industry, partnerships and collaborations with leading technology providers signal credibility. Companies that align with top-tier engineering firms and material scientists not only gain access to the latest technological advancements but also benefit from shared knowledge that pushes industry standards forward. Trustworthiness in this sector largely hinges on delivering consistent, high-quality products. Therefore, many leading rolling mill providers emphasize transparency in their processes, inviting customers to tour facilities, witness operations firsthand, and initiate dialogues about challenges and solutions. Such openness fosters trust and solidifies reputations in a competitive marketplace. Embracing advanced analytics and IoT in the operation of rolling mills is also enhancing trust. Real-time data collection enables continuous monitoring of the machinery's performance, predicting maintenance needs before they result in costly repairs and ensuring that production runs smoothly without unexpected interruptions. This adoption of technology not only optimizes operations but also reinforces a commitment to reliability and innovation. In conclusion, for stakeholders in the sheet metal rolling mill industry, focusing on experience, expertise, authoritativeness, and trustworthiness is paramount. By leveraging cutting-edge technology, understanding material science intricacies, and prioritizing open communication, businesses can maintain a competitive edge, delivering high-quality, reliable metal sheet products that meet rigorous industry standards.

The expertise involved in running a sheet metal rolling mill extends beyond mechanical proficiency. Operators must be knowledgeable about material science to make informed decisions about metal types, as different metals react uniquely under pressure and temperature variations. This understanding directly impacts the product's quality, necessitating continual education and training to keep abreast of industry advancements. When it comes to showcasing authority in the sheet metal rolling mill industry, partnerships and collaborations with leading technology providers signal credibility. Companies that align with top-tier engineering firms and material scientists not only gain access to the latest technological advancements but also benefit from shared knowledge that pushes industry standards forward. Trustworthiness in this sector largely hinges on delivering consistent, high-quality products. Therefore, many leading rolling mill providers emphasize transparency in their processes, inviting customers to tour facilities, witness operations firsthand, and initiate dialogues about challenges and solutions. Such openness fosters trust and solidifies reputations in a competitive marketplace. Embracing advanced analytics and IoT in the operation of rolling mills is also enhancing trust. Real-time data collection enables continuous monitoring of the machinery's performance, predicting maintenance needs before they result in costly repairs and ensuring that production runs smoothly without unexpected interruptions. This adoption of technology not only optimizes operations but also reinforces a commitment to reliability and innovation. In conclusion, for stakeholders in the sheet metal rolling mill industry, focusing on experience, expertise, authoritativeness, and trustworthiness is paramount. By leveraging cutting-edge technology, understanding material science intricacies, and prioritizing open communication, businesses can maintain a competitive edge, delivering high-quality, reliable metal sheet products that meet rigorous industry standards.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products