schmalbandwerk

Feb . 13, 2025 13:38

Back to list

schmalbandwerk

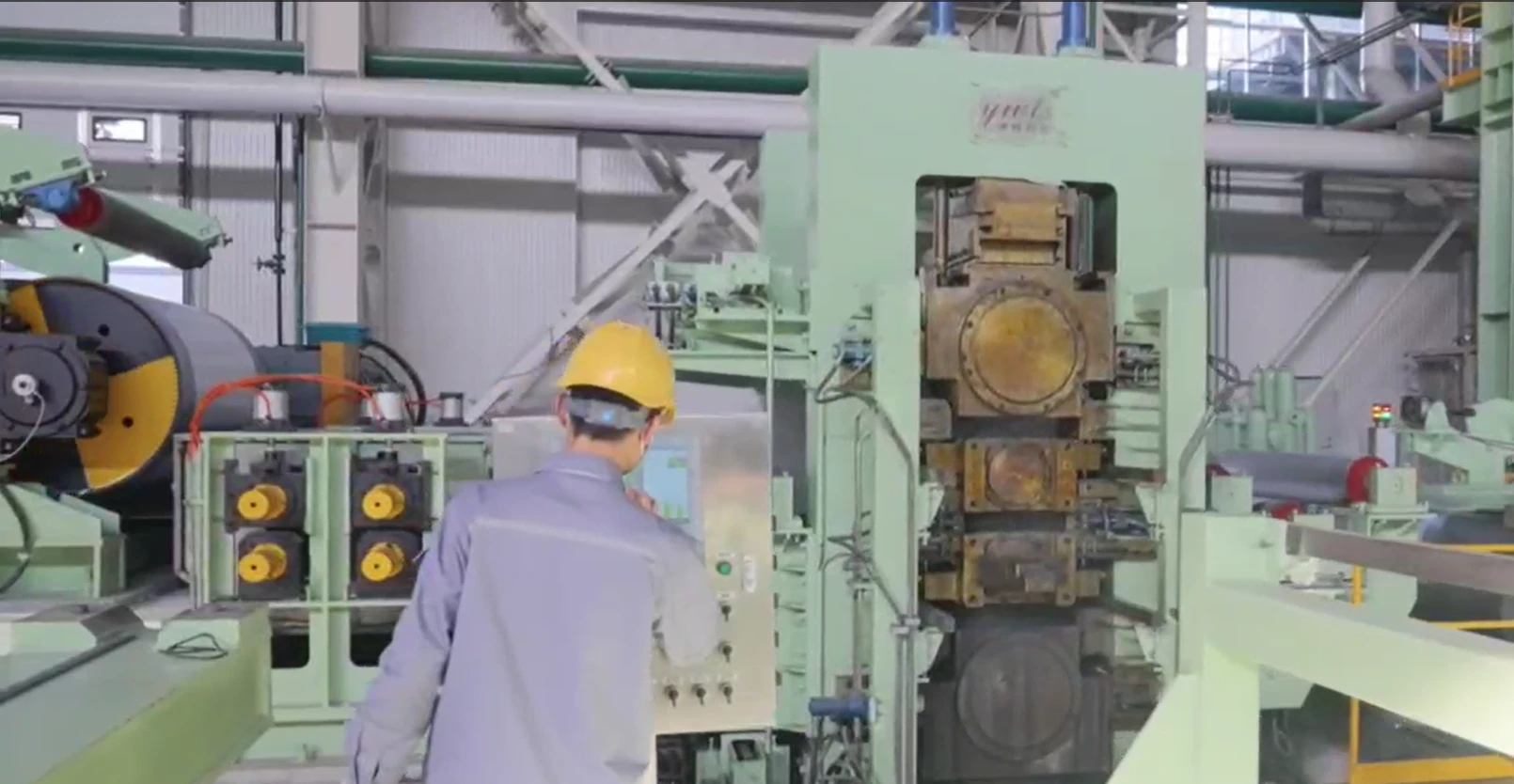

Navigating the world of industrial processes requires precision and efficiency, particularly when dealing with the unique demands of metal fabrication. The term schmalbandwerk, though not universally recognized, encapsulates a specific niche in the industrial sector that focuses on the production and use of narrow metal bands. These metal strips are essential components across various industries, including automotive, construction, and consumer electronics. As a seasoned expert in SEO and digital marketing, I've delved into the intricacies of schmalbandwerk, aiming to provide an in-depth exploration of this unique sector that balances innovation with practicality.

Emphasizing trustworthiness is equally crucial within the schmalbandwerk sector. Given the critical nature of the applications these metal bands often serve, errors or lapses in production can lead to significant operational setbacks or safety hazards. Therefore, manufacturers must rely on robust testing protocols and continuous inspection regimens. Close collaboration with industry experts and ongoing training initiatives further establish trust as manufacturers remain up-to-date on technological advancements and industry-leading techniques. The future of the schmalbandwerk industry is inherently linked to continuous advancements in technology and an unwavering commitment to sustainability. As environmental concerns become increasingly pronounced, many manufacturers are exploring eco-friendly alternatives and sustainable production practices. This shift not only aligns with global environmental goals but also anticipates client demands for ethically manufactured products. The integration of cutting-edge technologies such as AI and IoT in production processes also highlights a commitment to future-proofing operations, ensuring efficiency and accuracy remain at the forefront of schmalbandwerk production. In summary, schmalbandwerk embodies a unique blend of precision engineering, expert knowledge, and unwavering commitment to quality and trustworthiness. Its role within diverse industries underscores the necessity of maintaining rigorous standards and embracing innovation. Whether it's enhancing vehicle safety or supporting delicate electronic devices, the importance of schmalbandwerk lies in its ability to adapt and evolve, meeting the ever-changing demands of modern industry. By prioritizing expertise, authority, and trustworthiness, companies specializing in schmalbandwerk can continue to thrive in a competitive global landscape, laying the groundwork for a future defined by innovation and sustainability.

Emphasizing trustworthiness is equally crucial within the schmalbandwerk sector. Given the critical nature of the applications these metal bands often serve, errors or lapses in production can lead to significant operational setbacks or safety hazards. Therefore, manufacturers must rely on robust testing protocols and continuous inspection regimens. Close collaboration with industry experts and ongoing training initiatives further establish trust as manufacturers remain up-to-date on technological advancements and industry-leading techniques. The future of the schmalbandwerk industry is inherently linked to continuous advancements in technology and an unwavering commitment to sustainability. As environmental concerns become increasingly pronounced, many manufacturers are exploring eco-friendly alternatives and sustainable production practices. This shift not only aligns with global environmental goals but also anticipates client demands for ethically manufactured products. The integration of cutting-edge technologies such as AI and IoT in production processes also highlights a commitment to future-proofing operations, ensuring efficiency and accuracy remain at the forefront of schmalbandwerk production. In summary, schmalbandwerk embodies a unique blend of precision engineering, expert knowledge, and unwavering commitment to quality and trustworthiness. Its role within diverse industries underscores the necessity of maintaining rigorous standards and embracing innovation. Whether it's enhancing vehicle safety or supporting delicate electronic devices, the importance of schmalbandwerk lies in its ability to adapt and evolve, meeting the ever-changing demands of modern industry. By prioritizing expertise, authority, and trustworthiness, companies specializing in schmalbandwerk can continue to thrive in a competitive global landscape, laying the groundwork for a future defined by innovation and sustainability.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products