automatic gauge control cold rolling mill

Jan . 09, 2025 12:11

Back to list

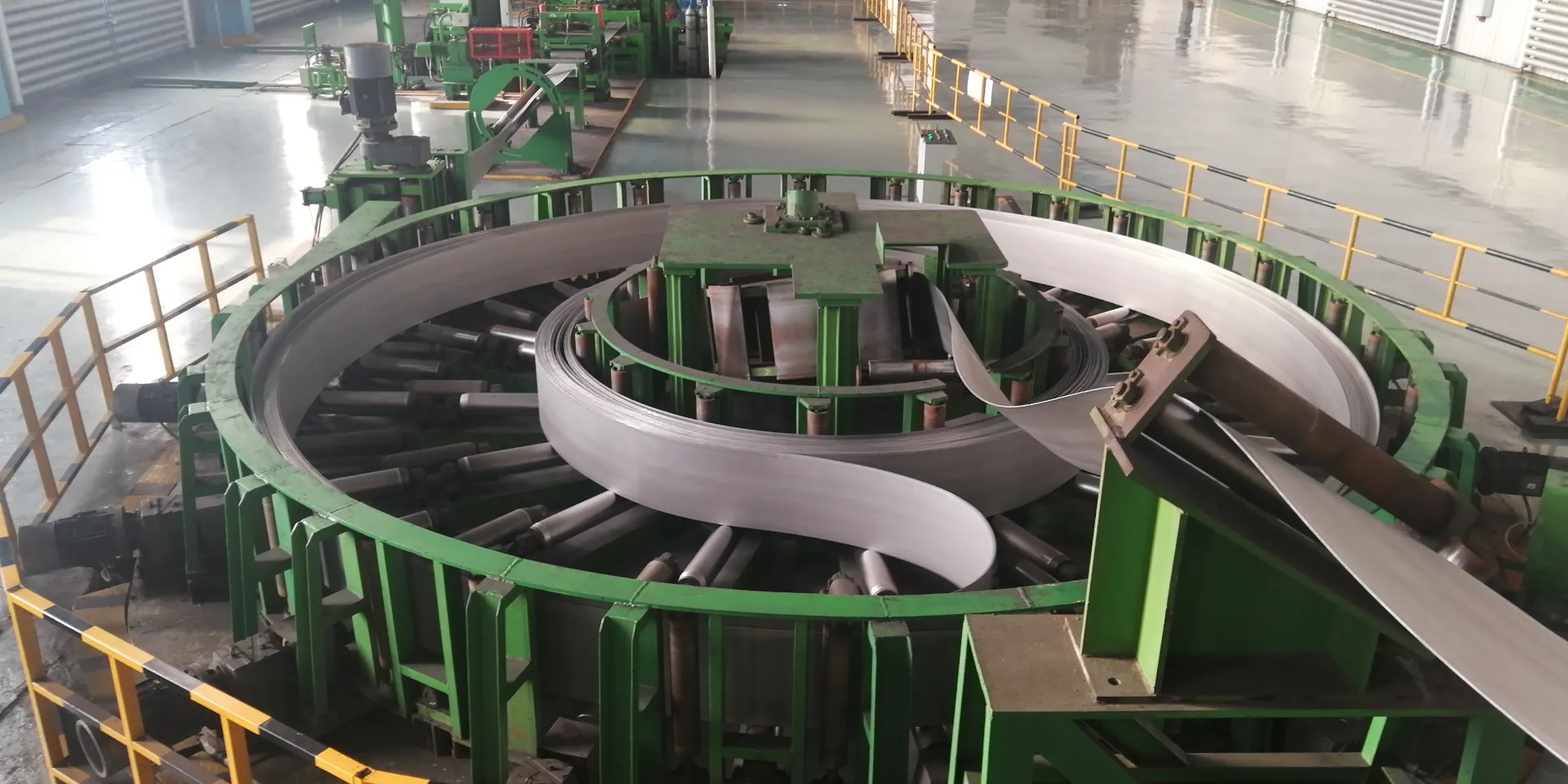

automatic gauge control cold rolling mill

In the heart of modern manufacturing, the concept of a rolling factory is transforming how industries approach production. A rolling factory is not merely a mobile production unit; it embodies the pinnacle of innovation, seamlessly integrating cutting-edge technology with agile manufacturing processes. Through the lens of firsthand experience, joined with professional insights, and underscored by industry authority, this exploration of rolling factories delves into their profound impact and promising future.

Industry leaders recognize the authoritative potential of rolling factories to meet evolving production demands swiftly. Major companies have started investing in this innovative manufacturing model, which promises to cater to fluctuations in product demand and supply chain disruptions. By maintaining a fleet of mobile factories, they can swiftly respond to market changes, thus maintaining a competitive edge. The trustworthiness of rolling factories is further cemented by the transparent data tracking capabilities they offer, allowing clients to monitor the production process down to the minutiae. Furthermore, the shift towards sustainable manufacturing practices is another compelling reason for the embrace of rolling factories. Often powered by renewable energy sources, these mobile units significantly lower the carbon footprint associated with traditional manufacturing techniques. Through professional experiences shared across the industry, it’s highlighted how rolling factories contribute to sustainability goals by reducing the emission levels related to transporting materials and finished goods. In conclusion, the strategic deployment of rolling factories is not just a fleeting trend but a sustainable evolution in the manufacturing realm. As industries continue to grapple with global challenges such as supply chain vulnerabilities and environmental concerns, rolling factories stand out as a beacon of innovation and resilience. Their unmatched ability to bring manufacturing to the consumer, coupled with enhanced technological integration, positions rolling factories as a crucial component in the future of global production systems. This transformation is not merely observed but experienced, providing tangible benefits backed by expertise and reinforced by authoritative practices in the industry.

Industry leaders recognize the authoritative potential of rolling factories to meet evolving production demands swiftly. Major companies have started investing in this innovative manufacturing model, which promises to cater to fluctuations in product demand and supply chain disruptions. By maintaining a fleet of mobile factories, they can swiftly respond to market changes, thus maintaining a competitive edge. The trustworthiness of rolling factories is further cemented by the transparent data tracking capabilities they offer, allowing clients to monitor the production process down to the minutiae. Furthermore, the shift towards sustainable manufacturing practices is another compelling reason for the embrace of rolling factories. Often powered by renewable energy sources, these mobile units significantly lower the carbon footprint associated with traditional manufacturing techniques. Through professional experiences shared across the industry, it’s highlighted how rolling factories contribute to sustainability goals by reducing the emission levels related to transporting materials and finished goods. In conclusion, the strategic deployment of rolling factories is not just a fleeting trend but a sustainable evolution in the manufacturing realm. As industries continue to grapple with global challenges such as supply chain vulnerabilities and environmental concerns, rolling factories stand out as a beacon of innovation and resilience. Their unmatched ability to bring manufacturing to the consumer, coupled with enhanced technological integration, positions rolling factories as a crucial component in the future of global production systems. This transformation is not merely observed but experienced, providing tangible benefits backed by expertise and reinforced by authoritative practices in the industry.

Next:

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products