rolled steel strip

Jan . 16, 2025 01:36

Back to list

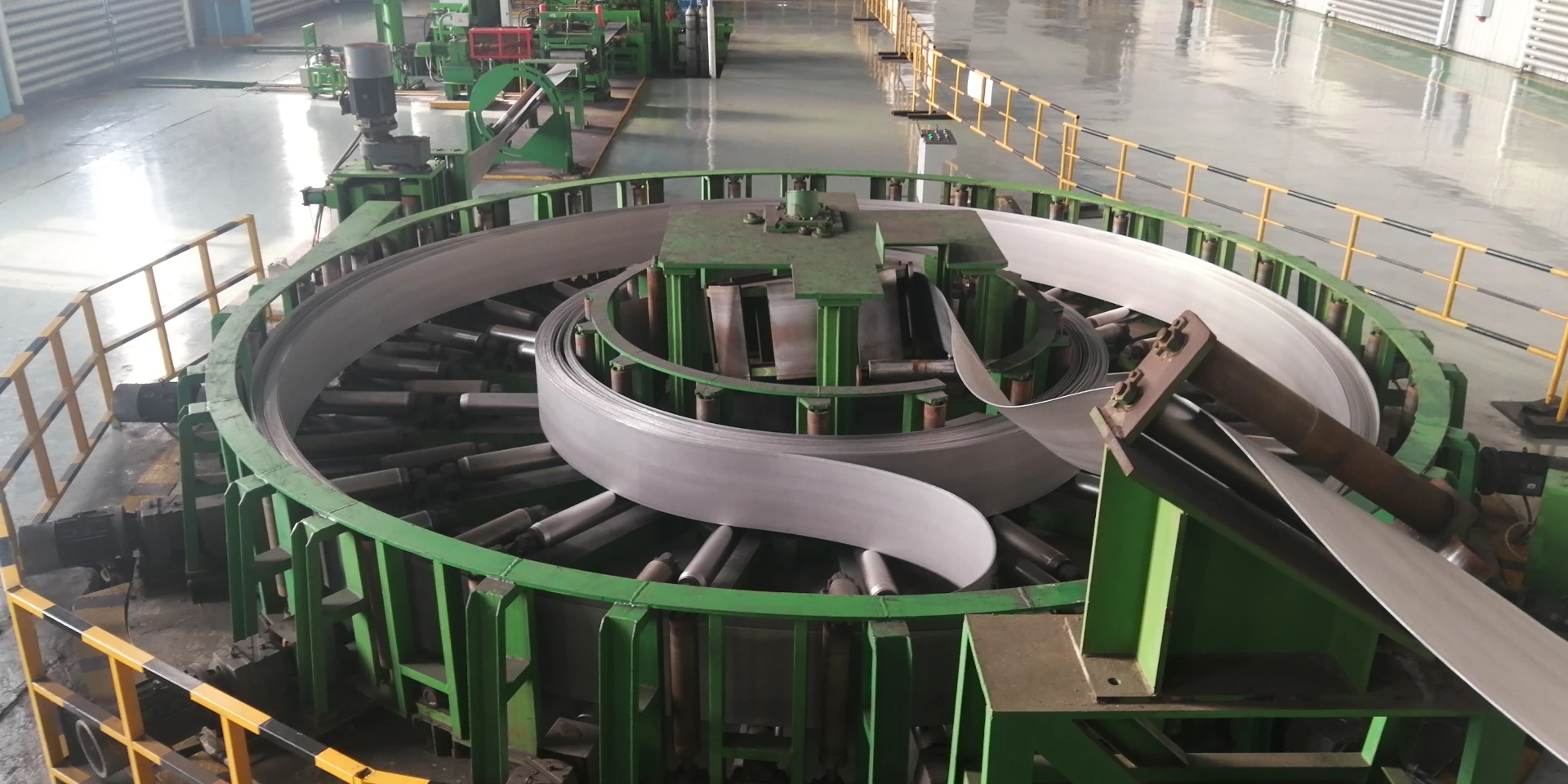

rolled steel strip

Rolled steel strip stands as a cornerstone in the realm of manufacturing and industrial applications. Its versatility and robustness make it an indispensable material across numerous sectors. This article delves into the multifaceted experience of utilizing rolled steel strips, emphasizing the technical expertise involved, its authoritative role in production, and the trustworthiness it offers to industries worldwide.

Authoritativeness in the realm of rolled steel strip production is rooted in the industry's reliance on certified standards and regulations. These standards, such as ASTM International and ISO certifications, are meticulously adhered to, ensuring that the steel strips produced meet globally recognized benchmarks for quality and performance. This adherence not only guarantees the product's reliability but also reinforces the manufacturer's credibility within the market. Companies producing rolled steel strips often collaborate with research institutions and leverage industry insights to remain at the forefront of innovation and sustainable practices. Trustworthiness is a core attribute of rolled steel strips, derived from their proven track record in demanding applications. For instance, in the construction industry, the durability and strength of steel strips are crucial for structural stability, particularly in frameworks and load-bearing structures. Similarly, in the automotive sector, the use of steel strips in components such as suspension systems and body panels exemplifies their reliability under stress and variable conditions. These real-world applications showcase how industries trust rolled steel strips for their longevity and resilience, building confidence in their consistent performance. In conclusion, rolled steel strips encapsulate the essence of efficient, precision-driven manufacturing. They offer a fusion of experience, expertise, authoritativeness, and trustworthiness, crucial for any industry opting for durable and reliable metal solutions. As global demand for sustainable and efficient materials surges, the role of rolled steel strips in meeting these standards continues to be of paramount importance, underscoring their status as a vital component in modern industrial applications.

Authoritativeness in the realm of rolled steel strip production is rooted in the industry's reliance on certified standards and regulations. These standards, such as ASTM International and ISO certifications, are meticulously adhered to, ensuring that the steel strips produced meet globally recognized benchmarks for quality and performance. This adherence not only guarantees the product's reliability but also reinforces the manufacturer's credibility within the market. Companies producing rolled steel strips often collaborate with research institutions and leverage industry insights to remain at the forefront of innovation and sustainable practices. Trustworthiness is a core attribute of rolled steel strips, derived from their proven track record in demanding applications. For instance, in the construction industry, the durability and strength of steel strips are crucial for structural stability, particularly in frameworks and load-bearing structures. Similarly, in the automotive sector, the use of steel strips in components such as suspension systems and body panels exemplifies their reliability under stress and variable conditions. These real-world applications showcase how industries trust rolled steel strips for their longevity and resilience, building confidence in their consistent performance. In conclusion, rolled steel strips encapsulate the essence of efficient, precision-driven manufacturing. They offer a fusion of experience, expertise, authoritativeness, and trustworthiness, crucial for any industry opting for durable and reliable metal solutions. As global demand for sustainable and efficient materials surges, the role of rolled steel strips in meeting these standards continues to be of paramount importance, underscoring their status as a vital component in modern industrial applications.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products