rolle-zu-rolle-spannungsregelung

Feb . 15, 2025 22:57

Back to list

rolle-zu-rolle-spannungsregelung

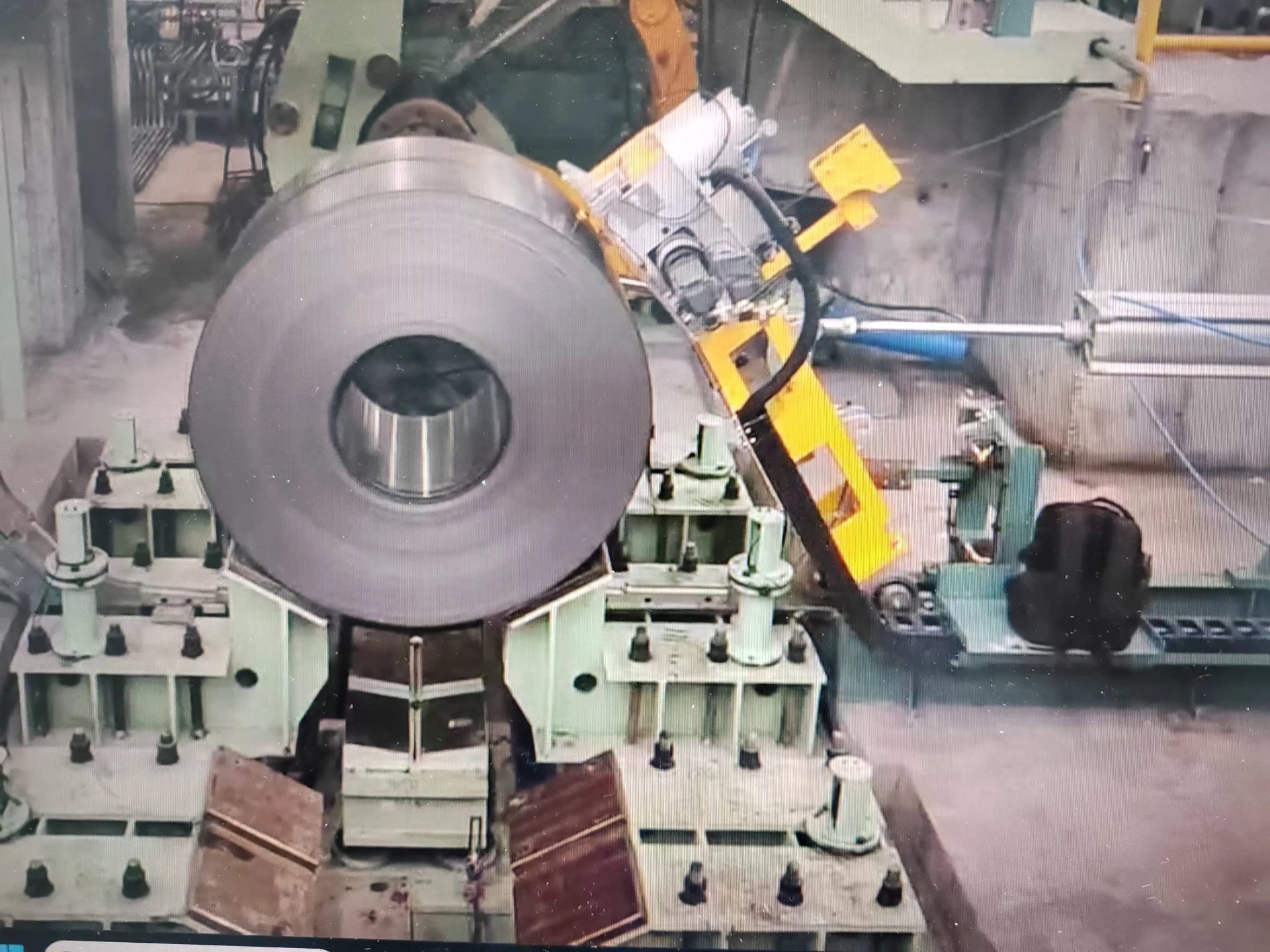

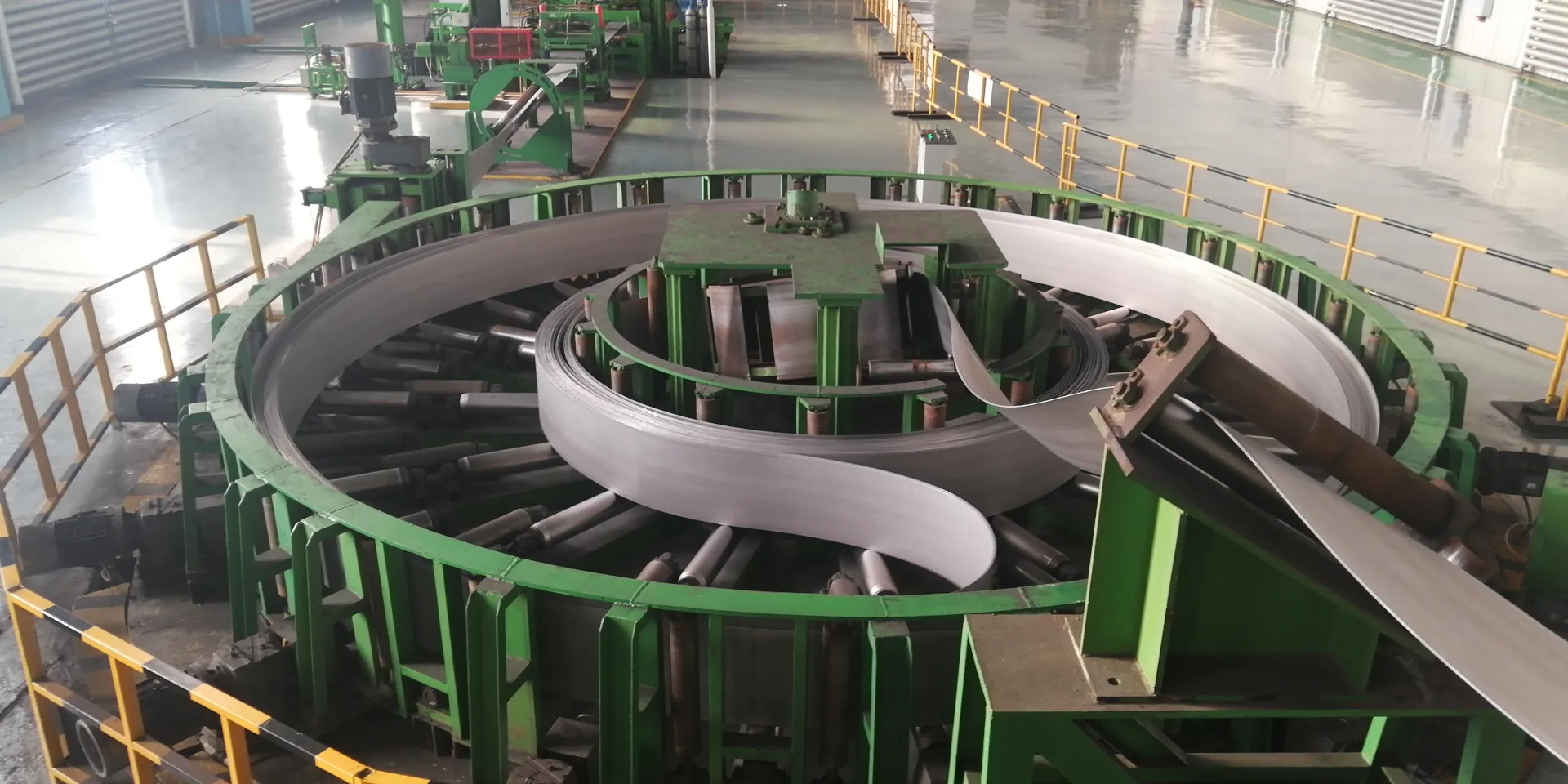

Roll-to-roll tension control has rapidly evolved in recent years as a critical component across various industries including packaging, textiles, and electronics manufacturing. This pivotal process not only enhances the efficiency of production lines but also significantly boosts the quality of the final products. This article dives deep into the sophisticated world of roll-to-roll tension control systems, exploring their functionalities, benefits, and the critical role they play in modern industrial processes.

From an expertise standpoint, developing a robust roll-to-roll tension control solution requires a deep understanding of material properties, machine dynamics, and control theory. Industry leaders boast engineering teams that continuously innovate to enhance system capabilities. These teams often collaborate with academic researchers to incorporate cutting-edge technology, such as machine learning algorithms, for predictive tension management. Such advancements ensure that even as materials and production techniques evolve, roll-to-roll systems remain ahead of the curve. In terms of authority, the impact of reputable certifications cannot be overstated. Adherence to industrial standards and certifications, such as those from the ISO or ANSI, affirms the quality and reliability of tension control systems. Companies who provide roll-to-roll tension control solutions often have these certifications as a testament to their commitment to excellence and customer satisfaction. Further, the global reach of these organizations and their partnerships with major manufacturers amplify their influence in the industry. Trustworthiness in roll-to-roll tension control systems is tied closely to their reliability and after-sales support. Manufacturers prioritize building durable systems equipped with redundancy features to prevent unexpected failures. A dedicated support team enhances trust, offering rapid troubleshooting and maintenance services to ensure minimal disruption. Additionally, customer training sessions and extensive documentation empower users to operate the systems with confidence. In conclusion, the field of roll-to-roll tension control continues to expand and innovate, driven by the ever-increasing demands of industries seeking efficient and reliable production processes. Through technological advancement, strict adherence to quality standards, and unwavering commitment to customer support, roll-to-roll tension control systems have become indispensable allies in modern manufacturing environments. As businesses endeavor to improve their production capabilities, the adoption and refinement of tension control technologies will undoubtedly play a central role in achieving those goals.

From an expertise standpoint, developing a robust roll-to-roll tension control solution requires a deep understanding of material properties, machine dynamics, and control theory. Industry leaders boast engineering teams that continuously innovate to enhance system capabilities. These teams often collaborate with academic researchers to incorporate cutting-edge technology, such as machine learning algorithms, for predictive tension management. Such advancements ensure that even as materials and production techniques evolve, roll-to-roll systems remain ahead of the curve. In terms of authority, the impact of reputable certifications cannot be overstated. Adherence to industrial standards and certifications, such as those from the ISO or ANSI, affirms the quality and reliability of tension control systems. Companies who provide roll-to-roll tension control solutions often have these certifications as a testament to their commitment to excellence and customer satisfaction. Further, the global reach of these organizations and their partnerships with major manufacturers amplify their influence in the industry. Trustworthiness in roll-to-roll tension control systems is tied closely to their reliability and after-sales support. Manufacturers prioritize building durable systems equipped with redundancy features to prevent unexpected failures. A dedicated support team enhances trust, offering rapid troubleshooting and maintenance services to ensure minimal disruption. Additionally, customer training sessions and extensive documentation empower users to operate the systems with confidence. In conclusion, the field of roll-to-roll tension control continues to expand and innovate, driven by the ever-increasing demands of industries seeking efficient and reliable production processes. Through technological advancement, strict adherence to quality standards, and unwavering commitment to customer support, roll-to-roll tension control systems have become indispensable allies in modern manufacturing environments. As businesses endeavor to improve their production capabilities, the adoption and refinement of tension control technologies will undoubtedly play a central role in achieving those goals.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products