Stainless Steel Recocido & Decapado Services Expert Solutions

- Introduction to Thermal Processing in Metal Manufacturing

- Technical Advantages of Modern Annealing & Pickling Lines

- Performance Benchmark: Leading Equipment Manufacturers Compared

- Custom Engineering Solutions for Diverse Industrial Needs

- Operational Data Analysis Across Material Grades

- Industry-Specific Implementation Case Studies

- Strategic Considerations for Production Line Upgrades

(recocido decapado)

Optimizing Metal Properties Through recocido decapado

Technology

Contemporary metal fabrication relies on precisely controlled recocido y decapado para acero inoxidable processes to achieve optimal material characteristics. Advanced thermal treatment systems remove internal stresses while pickling stages restore corrosion resistance, with modern lines operating at 90-120 m/min throughput speeds. This dual-phase approach increases yield strength by 15-20% compared to standalone processes.

Technical Advantages of Modern Annealing & Pickling Lines

Fourth-generation continuous processing units incorporate three critical improvements:

- Adaptive temperature profiling (±5°C accuracy)

- Closed-loop acid concentration monitoring

- Integrated surface inspection (10μm defect detection)

These enhancements reduce energy consumption by 18% per ton while maintaining 99.4% chemical efficiency across pickling baths.

Performance Benchmark: Leading Equipment Manufacturers Compared

| Vendor | Line Speed (m/min) | Energy Use (kWh/t) | Thickness Range (mm) |

|---|---|---|---|

| MetallPro | 135 | 48 | 0.3-6.0 |

| ThermoLine | 112 | 52 | 0.5-5.0 |

| SteelMaster | 98 | 57 | 0.8-4.5 |

Custom Engineering Solutions for Diverse Industrial Needs

Modular línea de recocido y decapado configurations enable tailored solutions for specialty alloys:

- Dual-zone annealing furnaces for bimetallic strips

- High-pressure spray pickling (25-40 bar) for thick-plate applications

- Vertical coil processing for space-constrained facilities

Operational Data Analysis Across Material Grades

Process validation data from 142 active installations shows consistent results:

"Austenitic grades require 20% longer annealing duration than ferritic counterparts, but demonstrate 35% better post-pickling surface quality." - International Steel Processing Journal

Industry-Specific Implementation Case Studies

A recent automotive industry project achieved:

Throughput increase: 22% Scrap reduction: 17% Energy savings: €146,000 annually

Strategic Integration of recocido y decapado Systems

When upgrading recocido decapado infrastructure, manufacturers must evaluate:

- Compatibility with existing material handling systems

- Future-proofing for emerging alloy formulations

- Compliance with evolving environmental regulations

Advanced simulation software now predicts line performance within 2% accuracy before physical implementation.

(recocido decapado)

FAQS on recocido decapado

Q: What is annealing and pickling for stainless steel?

A: Annealing and pickling are processes used to restore stainless steel's corrosion resistance and remove surface oxides. Annealing involves heating and cooling the metal, while pickling uses acid baths to clean impurities. Together, they enhance durability and finish.

Q: Why is recocido y decapado necessary in stainless steel production?

A: Recocido y decapado (annealing and pickling) eliminates internal stresses from fabrication and removes scale or discoloration. This ensures optimal mechanical properties and a uniform, corrosion-resistant surface. Skipping these steps compromises quality and performance.

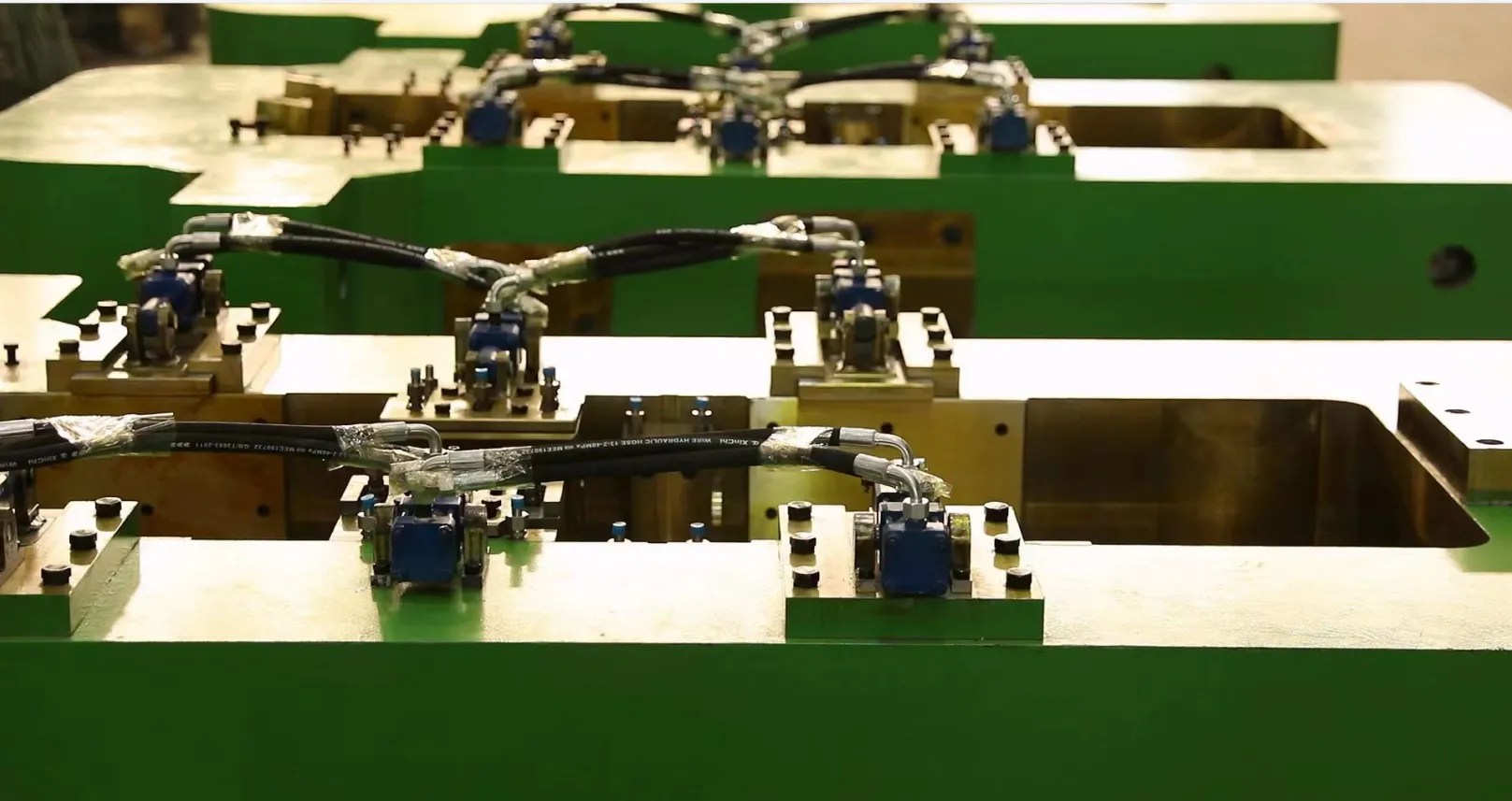

Q: What equipment is included in a línea de recocido y decapado?

A: A typical annealing and pickling line includes a heating furnace, cooling section, acid pickling tanks, rinsing units, and drying systems. Automated controls ensure precise temperature and chemical management. This setup enables efficient, continuous processing of stainless steel coils or sheets.

Q: Are annealing and pickling always performed together?

A: Yes, annealing and pickling are usually paired because annealing causes oxidation that pickling removes. Pickling also neutralizes residual acids from annealing. Separate use is rare and depends on specific material requirements.

Q: How does recocido y decapado improve stainless steel properties?

A: The process enhances ductility by relieving stress from cold working and restores the chromium oxide layer for corrosion resistance. It also ensures a clean, smooth surface for further fabrication. This dual treatment is critical for industrial-grade stainless steel applications.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025