News

-

In the vast and complex iron and steel industry chain, hot rolling mills stand as crucial processing units.Read more

In the vast and complex iron and steel industry chain, hot rolling mills stand as crucial processing units.Read more -

The hot rolling mill serves as the critical process stage where fundamental product quality characteristics are established.Read more

The hot rolling mill serves as the critical process stage where fundamental product quality characteristics are established.Read more -

The temperature at which hot rolling occurs is of utmost importance. Steel is typically rolled above its recrystallization temperature, usually around 900 - 1100°C for carbon steel.Read more

The temperature at which hot rolling occurs is of utmost importance. Steel is typically rolled above its recrystallization temperature, usually around 900 - 1100°C for carbon steel.Read more -

During the May Day holiday, while many people were enjoying their well - deserved breaks, the production workshop of YWLX was bustling with activity.Read more

During the May Day holiday, while many people were enjoying their well - deserved breaks, the production workshop of YWLX was bustling with activity.Read more -

In the dynamic world of industrial machinery, YWLX stands out as a professional and reliable manufacturer, offering a comprehensive range of products and services.Read more

In the dynamic world of industrial machinery, YWLX stands out as a professional and reliable manufacturer, offering a comprehensive range of products and services.Read more -

In the steel manufacturing industry, the temper mill operation is a crucial process that enhances the mechanical properties and surface quality of steel sheets.Read more

In the steel manufacturing industry, the temper mill operation is a crucial process that enhances the mechanical properties and surface quality of steel sheets.Read more -

In the bustling environment of a rolling factory, the bright annealing line stands as a crucial process for metal refinement.Read more

In the bustling environment of a rolling factory, the bright annealing line stands as a crucial process for metal refinement.Read more -

In the complex operations of a rolling factory, the pickling line is a critical process for preparing metal surfaces.Read more

In the complex operations of a rolling factory, the pickling line is a critical process for preparing metal surfaces.Read more -

A temper mill is an essential component in steel processing, especially when integrated with a bright annealing line.Read more

A temper mill is an essential component in steel processing, especially when integrated with a bright annealing line.Read more -

In the world of metal processing, the temper mill plays a pivotal role, especially within the context of an annealing line.Read more

In the world of metal processing, the temper mill plays a pivotal role, especially within the context of an annealing line.Read more -

In the steel manufacturing process, the temper mill is a critical piece of equipment used to improve the mechanical properties and surface quality of steel strips.Read more

In the steel manufacturing process, the temper mill is a critical piece of equipment used to improve the mechanical properties and surface quality of steel strips.Read more -

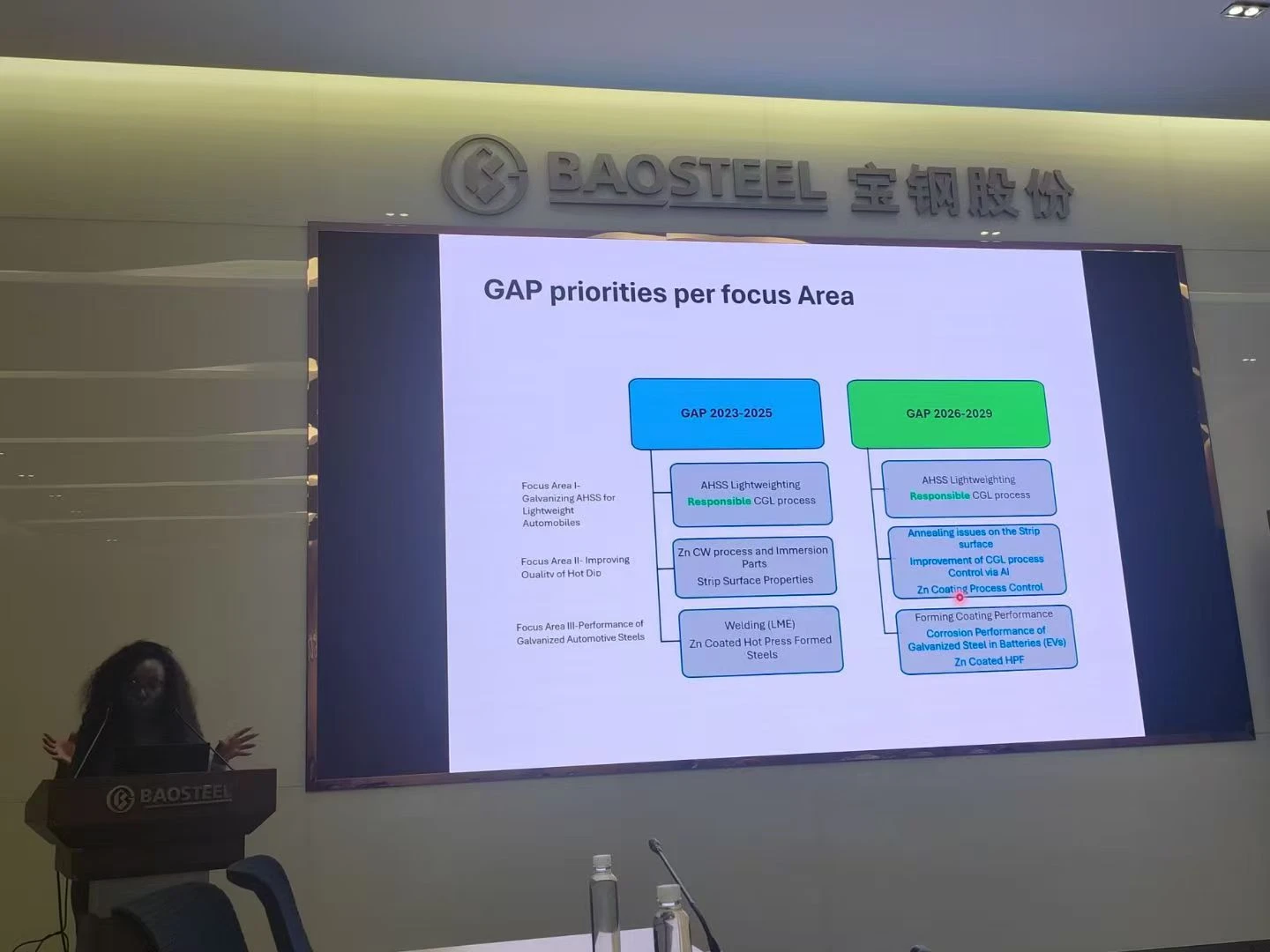

As a major supplier of skin pass mills for galvanizing lines, YWLX was invited to attend the 2025 ChRead more

As a major supplier of skin pass mills for galvanizing lines, YWLX was invited to attend the 2025 ChRead more