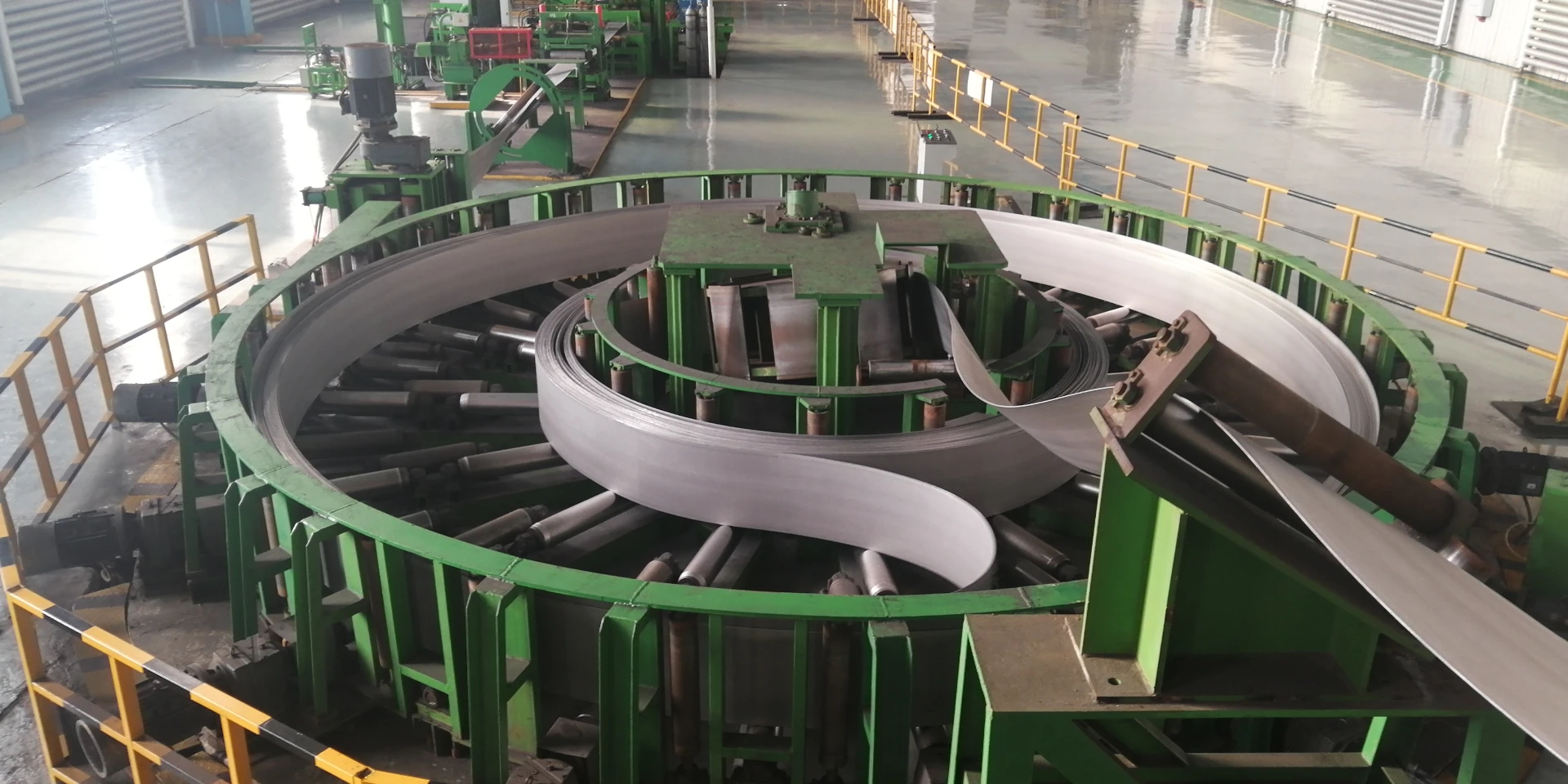

Hot/Cold Rolling Production Line

Feb . 10, 2025 12:40

Back to list

Hot/Cold Rolling Production Line

Steel rolling machines, integral to the metal fabrication industry, play a pivotal role in transforming raw materials into high-quality steel sheets and structures, essential for various applications worldwide. These machines are not mere equipment but the backbone of industries like construction, automotive, and even aerospace. Our deep dive into steel rolling machines highlights their technological advancements, operational methodologies, and their irreplaceable role within the manufacturing landscape.

While steel rolling machines are highly advanced, their operation is influenced by various external factors, such as the quality of the rollers themselves. Precision in the manufacturing of these components, alongside periodic maintenance checks, ensures that the machines perform at their peak capacity. Expertise in selecting the correct type of rollers for different steel grades enhances the productivity and efficiency of the rolling process. Real-world experience from industries utilizing these machines reveals the importance of regular calibration and testing of the machines to keep them aligned with the evolving industry standards. An accurately calibrated machine not only improves the consistency of the rolled steel but also reduces wastage, thereby increasing profitability and reducing environmental impact. In the pursuit of operational excellence, companies must also invest in training for their workforce to keep abreast of both fundamental techniques and the latest technological advancements in the industry. This commitment to continual improvement is a hallmark of industry leaders who drive innovation and efficiency. Furthermore, case studies from the field illustrate the diverse applications and advantages of rolled steel products in construction, where they contribute to the creation of resilient structures, or in automotive, where their lightweight yet robust characteristics are highly valued. Each application highlights the indispensable role of steel rolling machines in driving not just industry growth but also technological innovation. Overall, steel rolling machines symbolize more than just sophisticated hardware; they embody the intersection of human expertise and advanced technology working in harmony. Their complex operations and the critical role they play in modern manufacturing underline their importance across industries, making them a cornerstone of industrial development and an essential component in the supply chain of metal fabrication.

While steel rolling machines are highly advanced, their operation is influenced by various external factors, such as the quality of the rollers themselves. Precision in the manufacturing of these components, alongside periodic maintenance checks, ensures that the machines perform at their peak capacity. Expertise in selecting the correct type of rollers for different steel grades enhances the productivity and efficiency of the rolling process. Real-world experience from industries utilizing these machines reveals the importance of regular calibration and testing of the machines to keep them aligned with the evolving industry standards. An accurately calibrated machine not only improves the consistency of the rolled steel but also reduces wastage, thereby increasing profitability and reducing environmental impact. In the pursuit of operational excellence, companies must also invest in training for their workforce to keep abreast of both fundamental techniques and the latest technological advancements in the industry. This commitment to continual improvement is a hallmark of industry leaders who drive innovation and efficiency. Furthermore, case studies from the field illustrate the diverse applications and advantages of rolled steel products in construction, where they contribute to the creation of resilient structures, or in automotive, where their lightweight yet robust characteristics are highly valued. Each application highlights the indispensable role of steel rolling machines in driving not just industry growth but also technological innovation. Overall, steel rolling machines symbolize more than just sophisticated hardware; they embody the intersection of human expertise and advanced technology working in harmony. Their complex operations and the critical role they play in modern manufacturing underline their importance across industries, making them a cornerstone of industrial development and an essential component in the supply chain of metal fabrication.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products