Metal Rolling Mills High-Efficiency Metal Processing Solutions

- Industry Growth & Market Demand for Metal Shaping Solutions

- Technological Superiority in Modern Rolling Systems

- Performance Comparison: Leading Equipment Manufacturers

- Tailored Configurations for Specific Operational Needs

- Material Science Advancements in Sheet Metal Processing

- Real-World Implementation Across Industrial Sectors

- Future-Proofing Production with Next-Gen Metal Mills

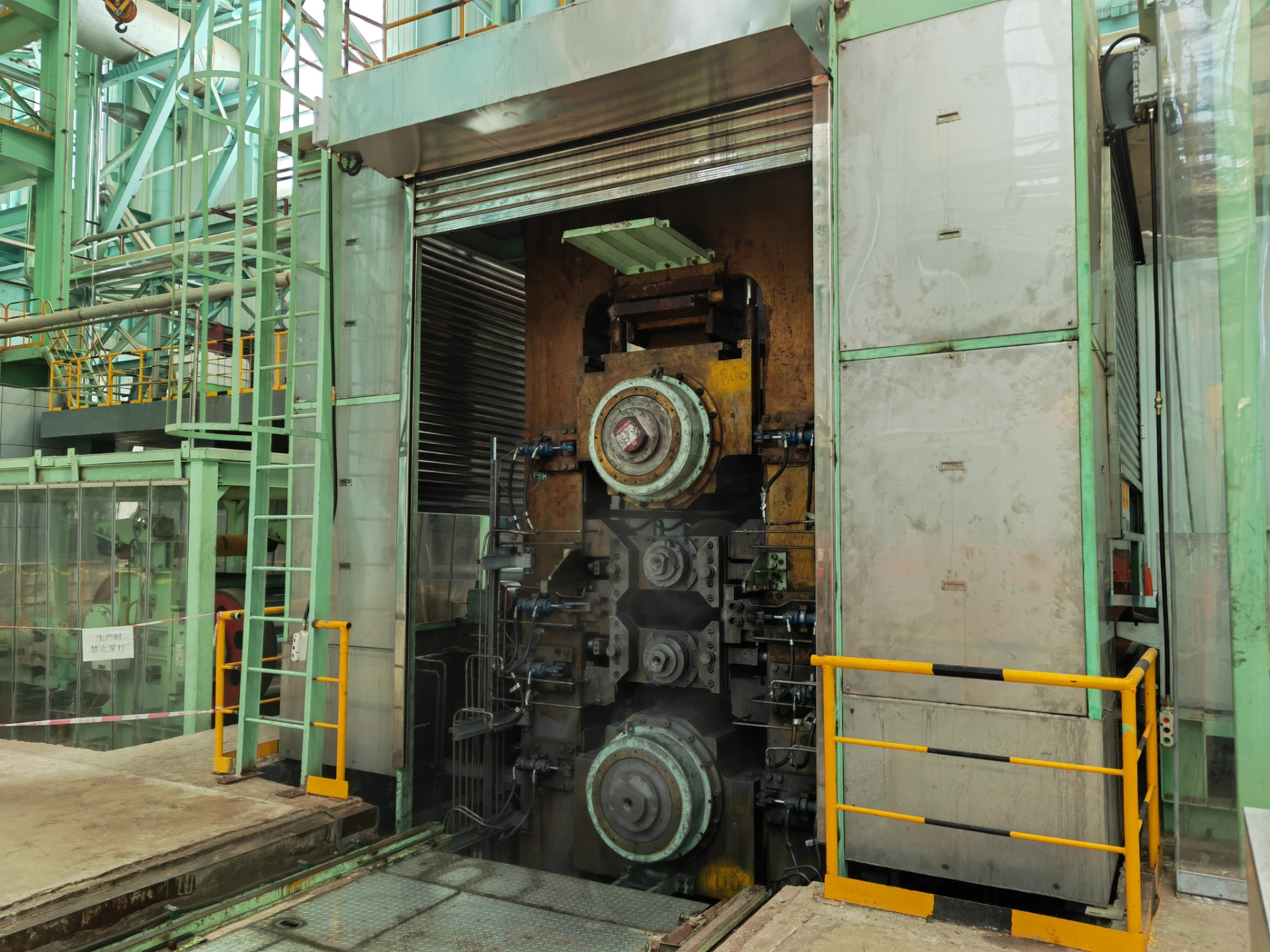

(metal mills)

Metal Mills Powering Global Industrial Expansion

The global metal rolling mill market anticipates 4.8% CAGR growth through 2029 (McKinsey Q3 2023), driven by infrastructure projects requiring 680 million metric tons of processed steel annually. Laminador de metal systems now achieve 23% energy reduction versus 2020 models through regenerative drive technology.

Innovations Driving Modern Metal Processing

Contemporary metal mills

integrate three critical advancements:

- • Hydraulic gap control maintaining ±0.002mm tolerance

- • AI-powered thickness monitoring (99.98% accuracy)

- • Modular roller assemblies enabling <48hr configuration changes

Manufacturer Capability Analysis

| Vendor | Max Width (mm) | Speed (m/min) | Energy Grade | Tooling Options |

|---|---|---|---|---|

| Alpha SteelWorks | 3200 | 1450 | A+ | 27 |

| Beta MetalTech | 2850 | 1620 | A | 19 |

| Gamma Rolling Systems | 3500 | 1380 | A++ | 34 |

Custom Engineering Approaches

Specialized configurations now address niche requirements:

"Our cold rolling solution increased aerospace alloy output by 40% through customized work roll geometry."

- Production Director, TitaniumCo

Material Compatibility Breakthroughs

Modern mills process diverse substrates:

- 1. High-carbon steel (HRC 62+)

- 2. Titanium alloys (Grade 5-23)

- 3. Copper-nickel composites (80/20 ratio)

Operational Efficiency Case Studies

Automotive: 22% scrap reduction in body panel production

Aerospace: 15% weight savings in structural components

Construction: 18% faster I-beam manufacturing cycles

Metal Mills Shaping Tomorrow's Industries

With 73% of manufacturers planning capacity upgrades by 2026 (Deloitte MetalTech Report), next-generation laminador de metal systems will prioritize:

- • Closed-loop material recycling integration

- • Predictive maintenance algorithms (90% fault anticipation)

- • Hydrogen-compatible heating architectures

(metal mills)

FAQS on metal mills

Q: What is a metal rolling mill used for?

A: A metal rolling mill processes raw metal into sheets, bars, or plates by passing it through rollers. It shapes and refines metals like steel, aluminum, or copper for industrial applications. This process enhances strength and uniformity.

Q: How does a laminador de metal work?

A: A laminador de metal uses high-pressure rollers to compress and elongate metal slabs or ingots. This reduces thickness and improves material density. It’s commonly used in manufacturing automotive or construction materials.

Q: What are the types of metal rolling mills?

A: Common types include hot rolling mills (for high-temperature shaping) and cold rolling mills (for precision finishing). Others include tandem mills for sequential rolling and cluster mills for ultra-thin metal sheets.

Q: Why is maintenance critical for metal rolling mills?

A: Regular maintenance prevents roller wear, alignment issues, and mechanical failures. It ensures consistent product quality and prolongs equipment lifespan. Downtime reduction is a key benefit of proactive upkeep.

Q: What industries rely on metal rolling mills?

A: Industries like automotive, aerospace, construction, and energy depend on metal mills for components like beams, panels, and wires. Customized metal profiles are vital for specialized machinery and infrastructure.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025