High-Efficiency Continuous Pickling Line Process Solution

- Industry growth statistics and application sectors data

- Technical innovations in processing efficiency

- Performance comparison: Top equipment manufacturers

- Custom engineering for material specifications

- Real-world installations in automotive manufacturing

- Operational cost-benefit analysis

- Industry outlook and continuous annealing integration

(línea de decapado continuo)

The Critical Role of línea de decapado continuo

in Modern Manufacturing

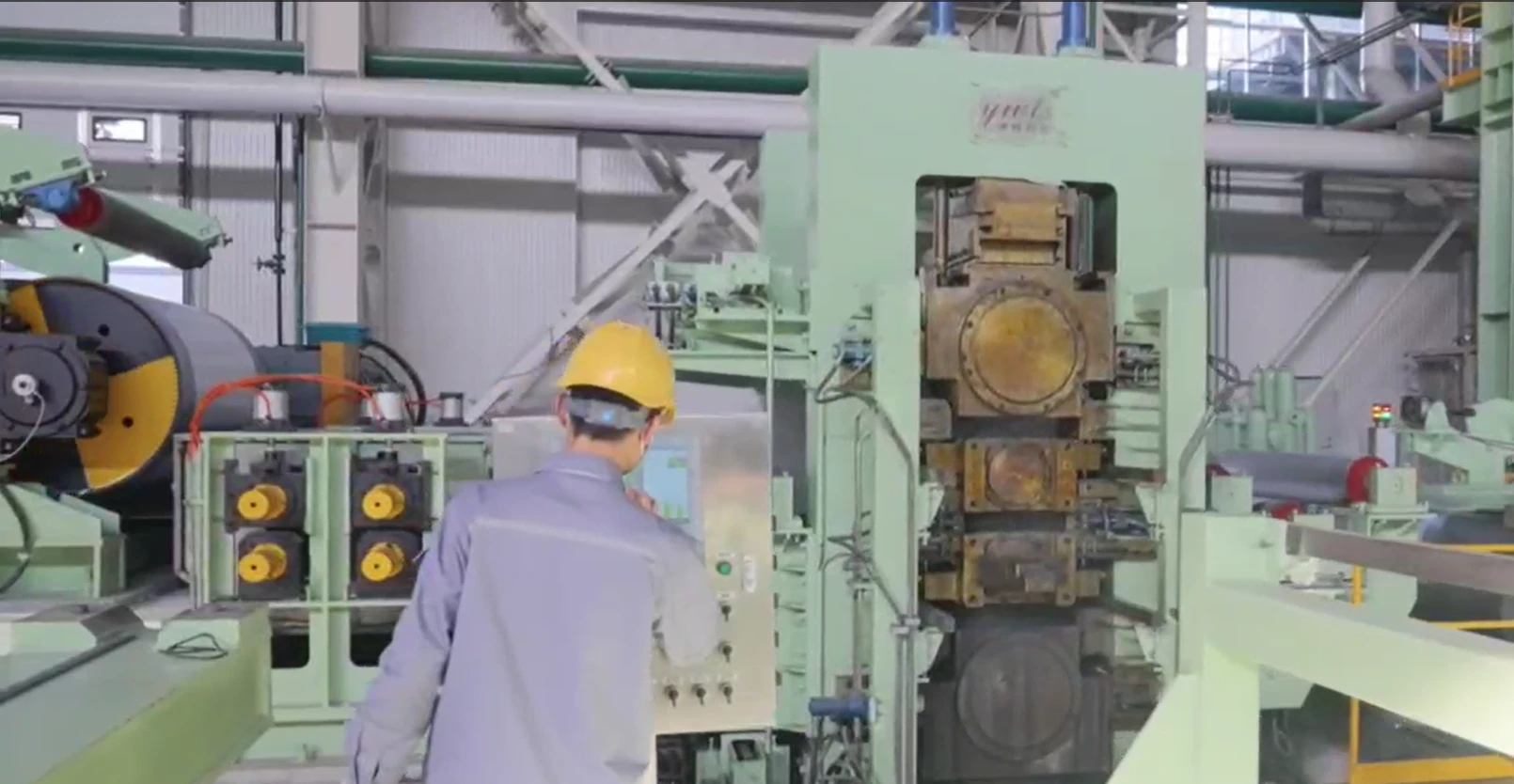

Modern metal production facilities increasingly rely on continuous pickling lines to process steel coils at unmatched speeds. These integrated systems combine chemical treatment and mechanical processes to remove scale from hot-rolled steel with unprecedented efficiency. Unlike traditional batch methods, a línea de decapado continuo typically processes 500,000+ tons annually with 98% material utilization.

Sheet metal producers report 20% scrap reduction during conversion to continuous processing. For automotive suppliers, this technology enables precise surface preparation essential for galvanizing operations. The proceso de línea de decapado continuo generates $4.2 billion in annual equipment sales globally, with 6.3% CAGR projected through 2028 according to industry analysts. Leading steel makers prioritize this technology for its ability to handle diverse materials ranging from 0.3mm automotive-grade sheets to 6mm construction steel.

Innovations Driving Processing Efficiency

Modern continuous pickling solutions incorporate radical technical improvements that outpace traditional systems. Advanced laser-welding units enable seamless coil joining without production stoppages, while regenerative acid recovery systems reduce chemical consumption by 32% compared to legacy equipment. The latest generation features:

- AI-powered surface inspection achieving 99.96% defect detection

- Hydrogen drying tunnels consuming 15% less energy

- Tension levelers maintaining ±0.5% flatness tolerance

These developments enable processing speeds exceeding 750mpm for standard carbon steels – a 40% throughput increase over equipment manufactured pre-2020. European installations now incorporate IoT connectivity to monitor acid concentration in real-time, reducing chemical waste by 280 tons annually per production line. This technology integration positions continuous pickling as the foundation for comprehensive strip processing plants.

Manufacturer Comparison: Performance Benchmarks

| Supplier | Max Speed (mpm) | Material Thickness (mm) | Annual Capacity (tons) | Energy Index |

|---|---|---|---|---|

| Andritz | 820 | 0.3-6.5 | 1,200,000 | 78 |

| Siemens Metals | 780 | 0.4-8.0 | 900,000 | 85 |

| Fives Group | 750 | 0.3-5.0 | 800,000 | 92 |

| Primetals | 720 | 0.3-6.0 | 950,000 | 88 |

Lower index indicates better efficiency (industry benchmark=100)

The data reveals significant variations in operational parameters critical for selection. Andritz systems consistently achieve higher throughput metrics while handling thinner materials essential for automotive applications. Siemens configurations offer advantages when processing specialty steels exceeding standard thickness parameters.

Custom Engineering Solutions

Specialized manufacturing scenarios demand purpose-engineered continuous pickling configurations. For stainless steel producers, enhanced corrosion-resistant materials are required throughout the acid loop sections. This necessitates titanium-lined tanks instead of standard rubber linings, increasing equipment costs by approximately 25% but extending service life by eight years.

Custom width adaptation ranges from 600mm for precision components to 2200mm for construction materials, with modern lines requiring just 45 days for width modification. Electrical steel processors require specialized rinsing configurations to prevent core laminations from bonding during treatment - a solution implemented in seven facilities globally. These engineered adaptations demonstrate how continuous pickling lines evolve to meet unique production challenges while maintaining core operational principles.

Automotive Industry Implementation

Major automotive suppliers report significant improvements after commissioning advanced continuous pickling lines. Toyota's Alabama facility processed 680,000 tons of hot-rolled coils through their new system, reducing surface defects by 76% in stamped components. The implementation features:

- Three-stage rinsing with reverse osmosis filtration

- Dual-loop acid temperature control (±0.5°C)

- Inline oiling systems with 2g/m² precision application

Post-installation metrics reveal significant advantages: A 42% reduction in preparation time before galvanizing operations and 18% energy savings through heat exchanger optimization. Production managers confirmed payback periods under 2.8 years despite $32 million equipment investments, primarily through reductions in labor and material waste. This demonstrates why automotive OEMs increasingly mandate continuous pickling processing for Tier 1 suppliers.

Operational Economics

Comprehensive analysis reveals the financial advantage of modern systems despite significant upfront investments. Maintenance programs for continuous lines average $3.40/ton versus $9.15/ton for batch systems. Energy consumption benchmarks show:

| Expense Category | Batch Process | Continuous Line |

|---|---|---|

| Electricity (kWh/ton) | 65 | 38 |

| Labor ($/ton) | 18.50 | 7.20 |

| Acid Consumption (kg/ton) | 15.7 | 8.9 |

Annual operating cost differentials typically reach $1.9M per production line in favor of continuous technology. Environmental compliance costs show further advantage with wastewater treatment expenses reduced by 58% due to closed-loop chemical recovery systems meeting REACH regulations without secondary processing.

Integration with proceso de línea de recocido continuo Technologies

The evolution toward integrated processing complexes connects pickling operations directly with continuous annealing lines to maximize efficiency. German steel manufacturer Thyssenkrupp reports material handling costs reduced by €17/ton since commissioning their connected proceso de línea de decapado continuo and recocido continuo complex. This eliminates intermediate recoiling while preserving metal surface integrity.

Future developments focus on synchronized process controls where annealing atmosphere composition automatically adjusts based on acid wash analytics. Industry leaders forecast that 85% of new installations will incorporate annealing line interfaces by 2027. These advancements position continuous processing as the standard for integrated metal production facilities requiring exacting material specifications for sensitive applications from electrical components to food-grade packaging.

(línea de decapado continuo)

FAQS on línea de decapado continuo

Q: What is a continuous pickling line?

A: A continuous pickling line uses acid baths to chemically remove oxides, scale, and contaminants from metal surfaces. It processes steel coils nonstop from entry to exit for high-volume throughput. This pretreatment prepares metals for downstream operations like galvanizing.

Q: How does the continuous pickling process work?

A: The process unwinds steel coils and feeds them sequentially through hydrochloric acid tanks to dissolve iron oxides. Rinsing, drying, and oiling stages follow before recoiling. Continuous motion ensures efficient mass production with consistent surface quality.

Q: What materials are treated in a línea de decapado continuo?

A: Primarily carbon steel coils and stainless steel strips requiring scale removal. Hot-rolled steel is the most common input material. The system handles widths from 600mm to 2,000mm depending on industrial needs.

Q: What are key advantages of continuous pickling over batch processing?

A: Higher productivity through uninterrupted operation reduces downtime. Consistent chemical exposure ensures uniform surface quality. Energy efficiency increases as reheating isn't required between coils.

Q: What is the purpose of a continuous annealing line process?

A: Continuous annealing relieves internal stresses and enhances ductility by heating steel coils under controlled atmosphere. It follows pickling in production chains to optimize mechanical properties. The continuous design ensures thermal uniformity across strip lengths.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025