laminatoio per metalli

Jan . 29, 2025 00:39

Back to list

laminatoio per metalli

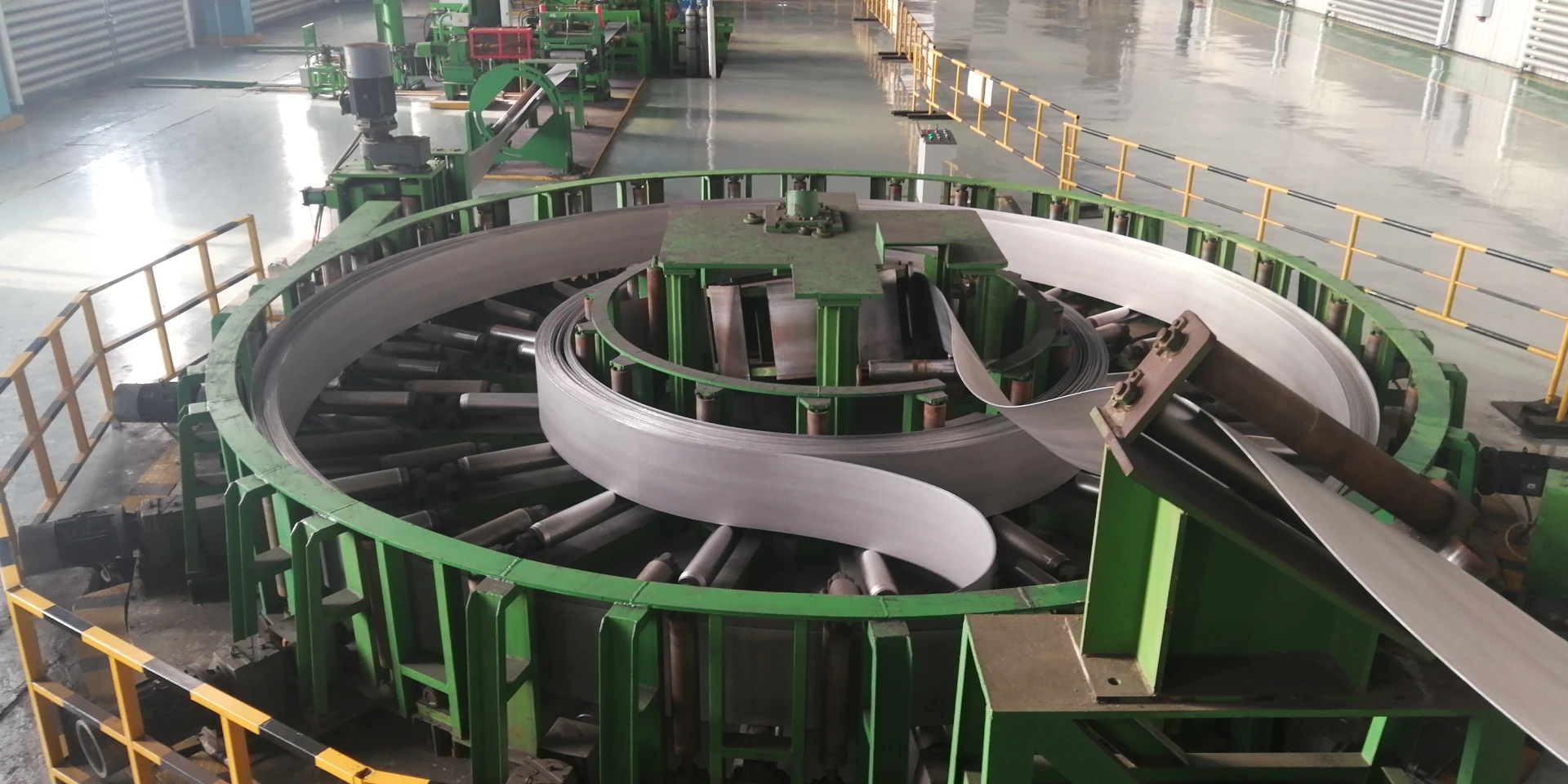

Metal rolling mills, both intricate in design and paramount in function, serve as the backbone of metal forming industries. They are critical for shaping raw metal into functional forms used across various sectors, from automotive to construction. With a focus on laminatoio per metalli, or metal rolling mills, it is essential to delve into the specifics, showcasing expertise and reliability, ensuring the reader garners an authoritative understanding of their significance.

In terms of authoritativeness, the suppliers and manufacturers of metal rolling mills champion innovations in the field. They lead research and development efforts to improve efficiency and reduce energy consumption, which aligns with global sustainability goals. Through continuous innovation, these manufacturers establish themselves as leaders in the metal forming sector. Furthermore, the evolution of digital solutions has revolutionized the operation and upkeep of rolling mills. Today, predictive maintenance solutions powered by AI and IoT provide invaluable data insights, allowing proactive upkeep of machinery, minimizing downtime, and enhancing operational efficiency. This technological leap not only demonstrates expertise but also enhances trust in the machinery’s reliability and longevity. For those who actively work with laminatoio per metalli, understanding their capabilities is vital. These machines are not just about bending or thinning metal. They refine the grain structure of the metal, improving its mechanical attributes, which is crucial for applications demanding high durability and strength. Hence, operators and engineers must possess a comprehensive understanding of the materials and processes involved to exploit the full potential of metal rolling mills. In conclusion, the pivotal role of laminatoio per metalli extends beyond mere machinery; they are fundamental to modern industry manufacturing needs. Mastery in their operation underscores deep expertise and technical prowess, which is critical for producing high-quality metal products. Their advanced features and technological integrations affirm their trustworthiness and authoritative role in the metal processing domain. Investing in knowledge and continual learning in this field not only enhances operational effectiveness but also ensures that one remains at the forefront of industry innovations, embodying true authority and reliability in the art of metal rolling.

In terms of authoritativeness, the suppliers and manufacturers of metal rolling mills champion innovations in the field. They lead research and development efforts to improve efficiency and reduce energy consumption, which aligns with global sustainability goals. Through continuous innovation, these manufacturers establish themselves as leaders in the metal forming sector. Furthermore, the evolution of digital solutions has revolutionized the operation and upkeep of rolling mills. Today, predictive maintenance solutions powered by AI and IoT provide invaluable data insights, allowing proactive upkeep of machinery, minimizing downtime, and enhancing operational efficiency. This technological leap not only demonstrates expertise but also enhances trust in the machinery’s reliability and longevity. For those who actively work with laminatoio per metalli, understanding their capabilities is vital. These machines are not just about bending or thinning metal. They refine the grain structure of the metal, improving its mechanical attributes, which is crucial for applications demanding high durability and strength. Hence, operators and engineers must possess a comprehensive understanding of the materials and processes involved to exploit the full potential of metal rolling mills. In conclusion, the pivotal role of laminatoio per metalli extends beyond mere machinery; they are fundamental to modern industry manufacturing needs. Mastery in their operation underscores deep expertise and technical prowess, which is critical for producing high-quality metal products. Their advanced features and technological integrations affirm their trustworthiness and authoritative role in the metal processing domain. Investing in knowledge and continual learning in this field not only enhances operational effectiveness but also ensures that one remains at the forefront of industry innovations, embodying true authority and reliability in the art of metal rolling.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products