hersteller von kaltwalzmaschinen

Feb . 12, 2025 02:45

Back to list

hersteller von kaltwalzmaschinen

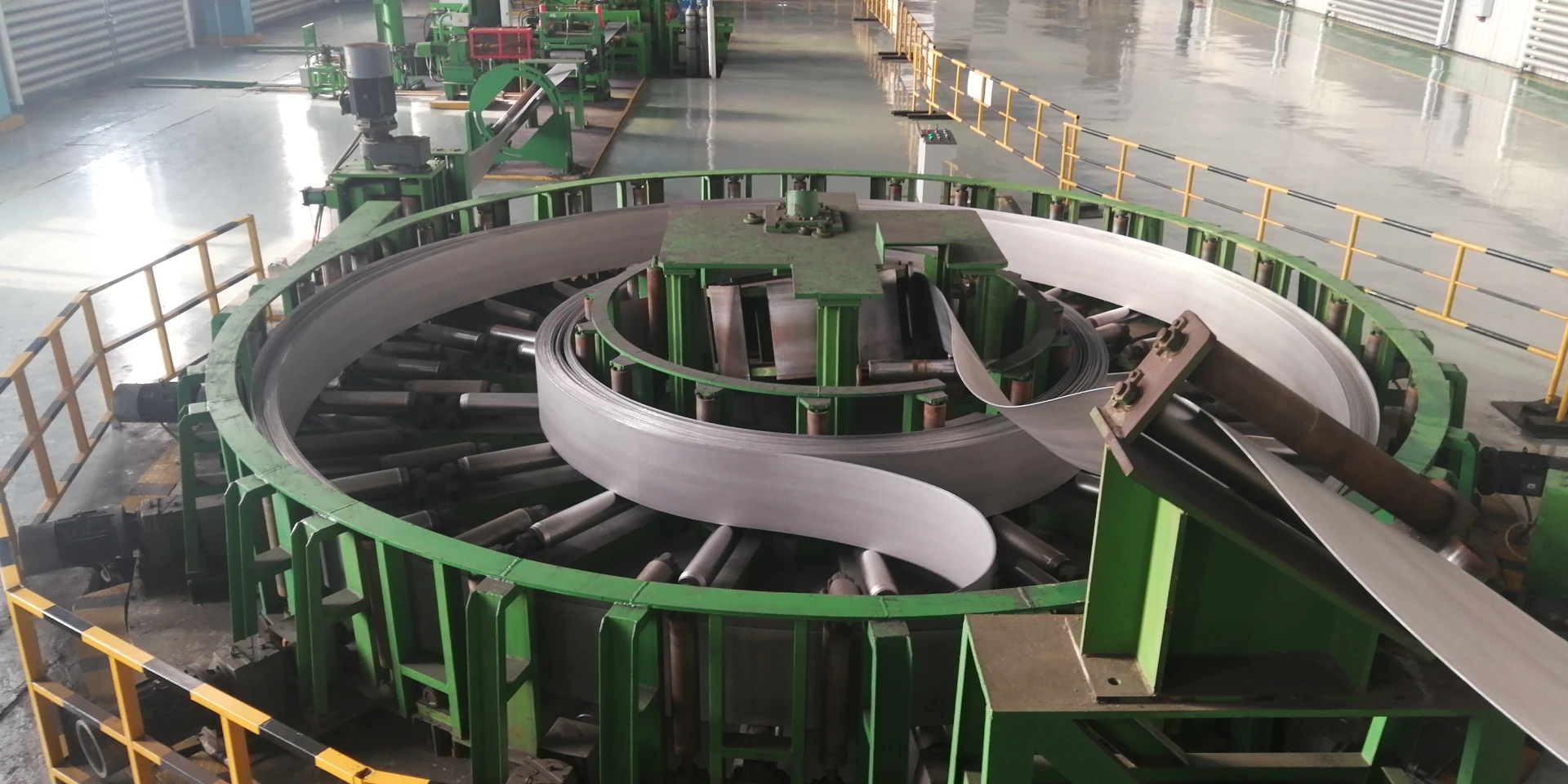

Manufacturers of cold rolling machines play a pivotal role in the metalworking and manufacturing industries. These machines, renowned for their efficiency and precision, are crucial for enhancing the mechanical properties of metal sheets and strips. With innovations constantly reshaping the landscape, understanding what sets top manufacturers apart is essential for businesses looking to make informed purchasing decisions.

A noteworthy trend among leading manufacturers is their focus on customization. Understanding that each client has unique needs, these companies offer tailored solutions to accommodate specific production requirements. Whether it’s modifying machine design or incorporating specialized features, the ability to provide bespoke solutions is a testament to a manufacturer’s adaptability and customer-centric approach. The authority of a manufacturer is often reflected in their global footprint and industry endorsements. Companies with a significant international presence and who regularly collaborate with renowned industry bodies effectively set benchmarks for quality and innovation. Such endorsements not only enhance a manufacturer's reputation but also assure potential customers of their reliability and industry standards compliance. In recent years, the integration of Industry 4.0 technologies into cold rolling machines has become a focal point for manufacturers aiming to enhance productivity and connectivity. By embedding IoT devices and sensors, manufacturers enable real-time monitoring and predictive maintenance, greatly reducing downtime and operational interruptions. Such advancements demonstrate the forward-thinking nature of these companies, as they continually align their offerings with the future of manufacturing. To remain competitive, leading manufacturers are increasingly focusing on sustainable practices, acknowledging the importance of environmental impact. They employ eco-friendly processes, recycle materials, and adhere to stringent environmental regulations, making strides towards a greener future. In conclusion, manufacturers of cold rolling machines distinguish themselves through a combination of experience, expertise, authority, and trustworthiness. By investing in state-of-the-art technology, committing to sustainability, and prioritizing customer satisfaction, they not only set the standard for quality but also pioneer advancements that shape the future of metal processing. Selecting a manufacturer that embodies these values ensures that businesses remain at the cutting edge of the industry, poised to meet current demands and future challenges with confidence.

A noteworthy trend among leading manufacturers is their focus on customization. Understanding that each client has unique needs, these companies offer tailored solutions to accommodate specific production requirements. Whether it’s modifying machine design or incorporating specialized features, the ability to provide bespoke solutions is a testament to a manufacturer’s adaptability and customer-centric approach. The authority of a manufacturer is often reflected in their global footprint and industry endorsements. Companies with a significant international presence and who regularly collaborate with renowned industry bodies effectively set benchmarks for quality and innovation. Such endorsements not only enhance a manufacturer's reputation but also assure potential customers of their reliability and industry standards compliance. In recent years, the integration of Industry 4.0 technologies into cold rolling machines has become a focal point for manufacturers aiming to enhance productivity and connectivity. By embedding IoT devices and sensors, manufacturers enable real-time monitoring and predictive maintenance, greatly reducing downtime and operational interruptions. Such advancements demonstrate the forward-thinking nature of these companies, as they continually align their offerings with the future of manufacturing. To remain competitive, leading manufacturers are increasingly focusing on sustainable practices, acknowledging the importance of environmental impact. They employ eco-friendly processes, recycle materials, and adhere to stringent environmental regulations, making strides towards a greener future. In conclusion, manufacturers of cold rolling machines distinguish themselves through a combination of experience, expertise, authority, and trustworthiness. By investing in state-of-the-art technology, committing to sustainability, and prioritizing customer satisfaction, they not only set the standard for quality but also pioneer advancements that shape the future of metal processing. Selecting a manufacturer that embodies these values ensures that businesses remain at the cutting edge of the industry, poised to meet current demands and future challenges with confidence.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products