fleje laminado en caliente

Feb . 11, 2025 12:13

Back to list

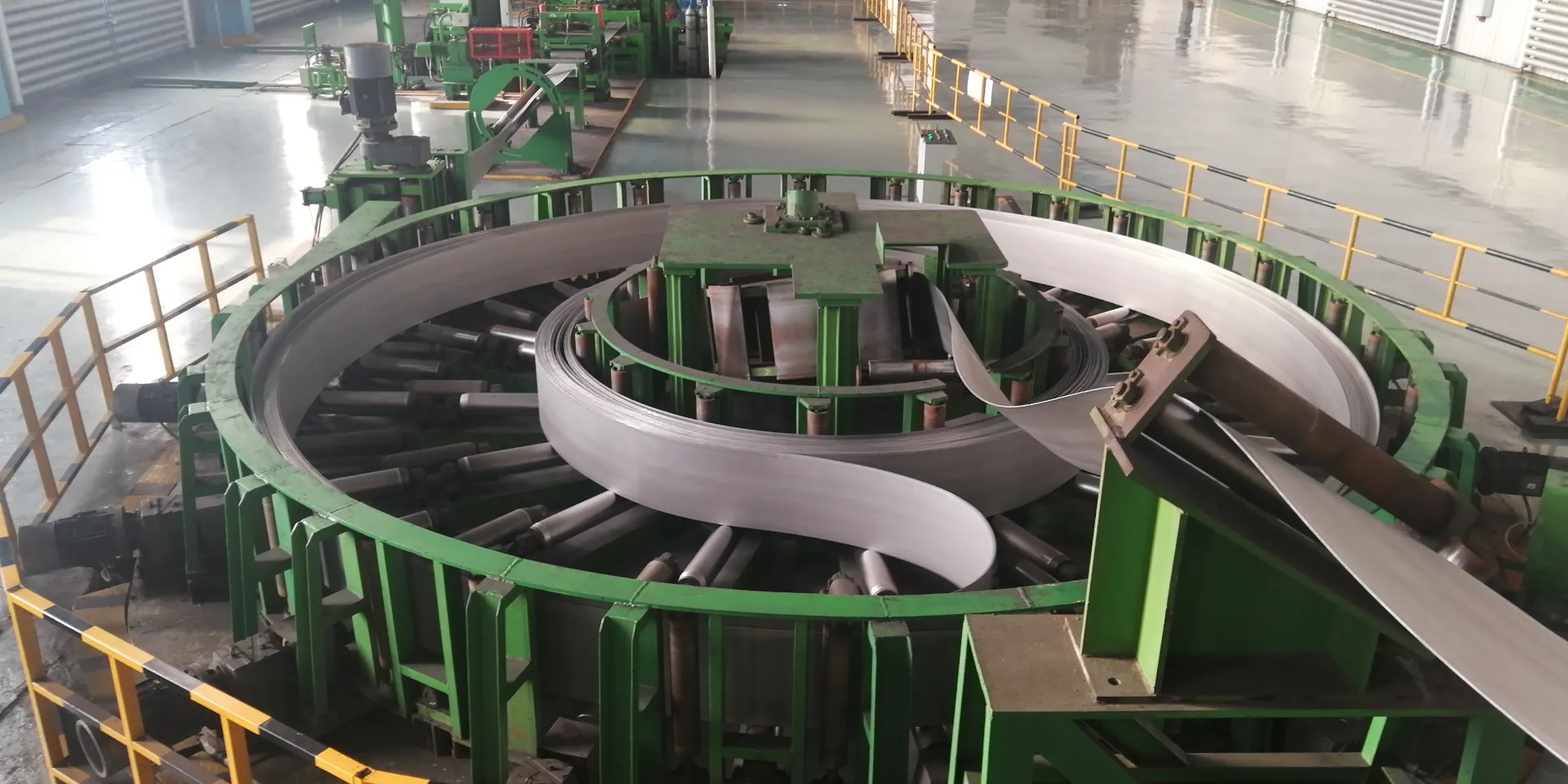

fleje laminado en caliente

Hot-rolled steel coils, commonly referred to in Spanish as fleje laminado en caliente, have revolutionized the way industries approach construction, automotive manufacture, and many other sectors. Utilizing a specific processing of heating steel above its recrystallization temperature, hot-rolled coils present numerous benefits that are foundational to their wide-ranging applications.

The expertise in the production process of hot-rolled coils is not just about achieving structural properties but also about optimizing cost-efficiency. The process, although conducted at high heat, is less intensive than producing cold-rolled steel, enabling manufacturers to produce large volumes efficiently. This economic production process translates to cost savings that are relayed down the supply chain, benefiting industries and end-users alike. Moreover, one cannot overlook the authority hot-rolled coils command in the market due to established use and reliability. Decades of utilization across numerous industrial applications have built a trustworthiness rapport for these materials. Industry standards for hot-rolled steel ensure consistent quality and performance, bolstering confidence among engineers and architects. In addition to their inherent qualities, hot-rolled coils are also subject to stringent testing and quality control measures. From tensile testing to assess strength and yield, to thickness measurements and surface finish assessments, manufacturers uphold rigor to certify that the steel meets both international and domestic standards. This focus on quality assurance underscores the reliability industries place on hot-rolled steel and reinforces its reputation as a trustworthy component in construction and manufacturing. In conclusion, fleje laminado en caliente offers unparalleled advantages in terms of strength, flexibility, cost-efficiency, and reliability. Its expert production and authoritative market presence ensure that it remains a cornerstone resource in steel fabrication. Industries relying on heavy-duty materials continue to find hot-rolled coils indispensable, and their continued innovation promises to uphold this legacy well into the future. From skyscrapers to high-speed trains, hot-rolled steel remains foundational, demonstrating experience, expertise, authority, and trustworthiness in every coil.

The expertise in the production process of hot-rolled coils is not just about achieving structural properties but also about optimizing cost-efficiency. The process, although conducted at high heat, is less intensive than producing cold-rolled steel, enabling manufacturers to produce large volumes efficiently. This economic production process translates to cost savings that are relayed down the supply chain, benefiting industries and end-users alike. Moreover, one cannot overlook the authority hot-rolled coils command in the market due to established use and reliability. Decades of utilization across numerous industrial applications have built a trustworthiness rapport for these materials. Industry standards for hot-rolled steel ensure consistent quality and performance, bolstering confidence among engineers and architects. In addition to their inherent qualities, hot-rolled coils are also subject to stringent testing and quality control measures. From tensile testing to assess strength and yield, to thickness measurements and surface finish assessments, manufacturers uphold rigor to certify that the steel meets both international and domestic standards. This focus on quality assurance underscores the reliability industries place on hot-rolled steel and reinforces its reputation as a trustworthy component in construction and manufacturing. In conclusion, fleje laminado en caliente offers unparalleled advantages in terms of strength, flexibility, cost-efficiency, and reliability. Its expert production and authoritative market presence ensure that it remains a cornerstone resource in steel fabrication. Industries relying on heavy-duty materials continue to find hot-rolled coils indispensable, and their continued innovation promises to uphold this legacy well into the future. From skyscrapers to high-speed trains, hot-rolled steel remains foundational, demonstrating experience, expertise, authority, and trustworthiness in every coil.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products