fleje de acero laminado

Feb . 11, 2025 15:14

Back to list

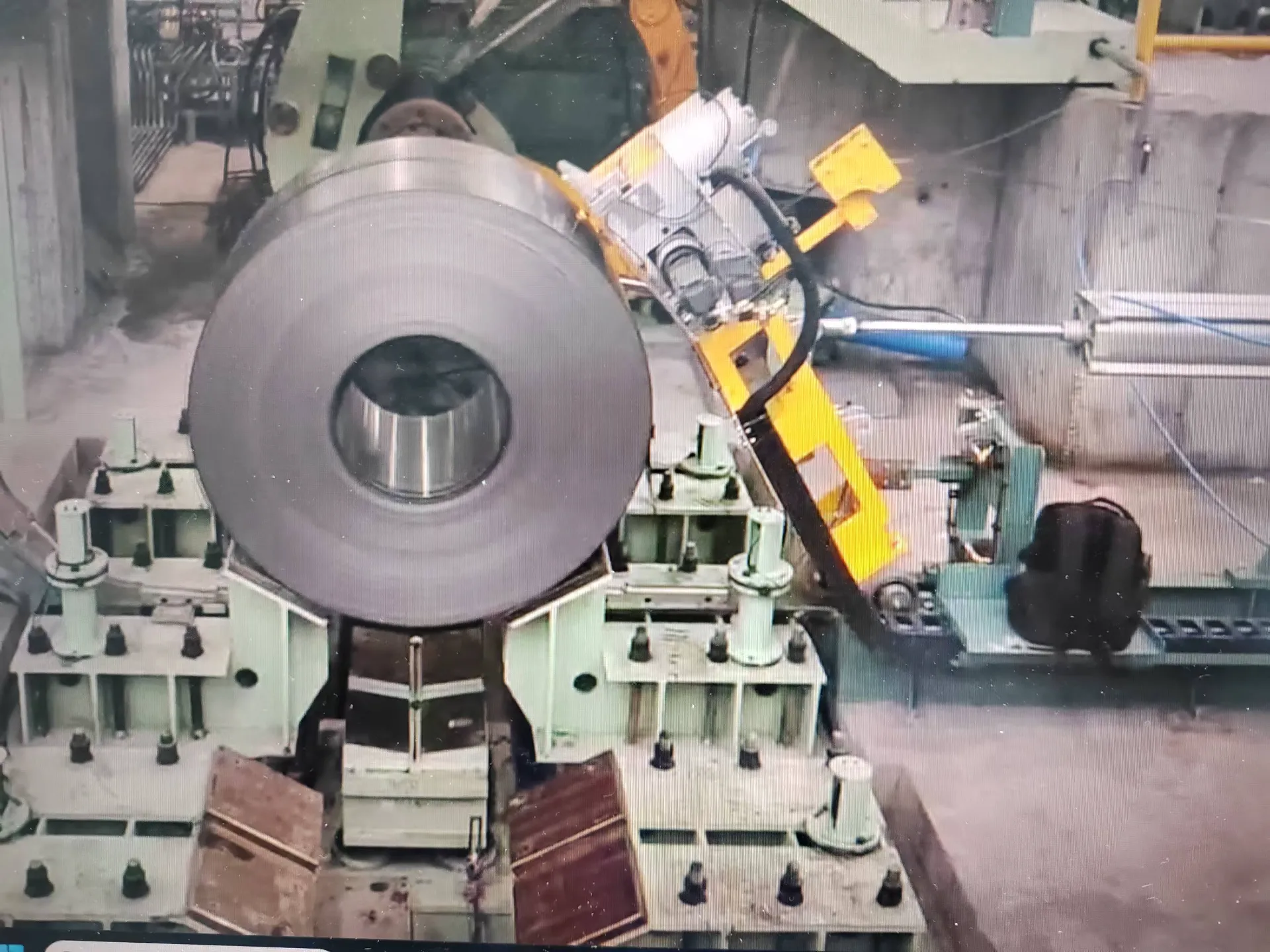

fleje de acero laminado

The world of industrial manufacturing demands products that are not only robust but also versatile and reliable. One prime example of such a product in the metalworking industry is the hot-rolled steel strip, or fleje de acero laminado as it is referred to in Spanish-speaking regions. These steel strips are the backbone of countless manufacturing applications and are known for their strength, durability, and flexibility.

However, expertise in utilizing hot-rolled steel strips is vital to leveraging these benefits efficiently. Professionals in the field recommend careful consideration of the end-use of each application. For high-precision components, it might be necessary to undergo further processing, such as pickling or oiling, to improve surface quality. Furthermore, adjustments to thickness tolerances and mechanical properties can be achieved through additional tempering processes based on specific requirements. Authoritativeness in the industry is often demonstrated by adhering to high standards and certifications specific to steel production. Compliance with international quality standards, such as ISO 9001 or the American Society for Testing and Materials (ASTM), assures customers of a product's performance and consistency. Other certifications may focus on environmental standards, highlighting a company's commitment to sustainable manufacturing practices. Trustworthiness of hot-rolled steel strip suppliers often correlates with their ability to provide consistent quality and reliable logistic solutions. End-users demand materials that not only meet engineering specifications but also are delivered on time and within budget. Building long-term relationships in the supply chain through demonstrated reliability and transparency can lead to repeat business and a strong reputation. In conclusion, the fleje de acero laminado stands as a pillar of strength and utility in the modern manufacturing landscape. Grounded in experience and expertise, backed by authoritativeness and trust, these steel strips continue to support a wide array of industrial applications. The continued evolution of processing technologies and quality standards promises even greater capabilities and applications for this indispensable material in the future.

However, expertise in utilizing hot-rolled steel strips is vital to leveraging these benefits efficiently. Professionals in the field recommend careful consideration of the end-use of each application. For high-precision components, it might be necessary to undergo further processing, such as pickling or oiling, to improve surface quality. Furthermore, adjustments to thickness tolerances and mechanical properties can be achieved through additional tempering processes based on specific requirements. Authoritativeness in the industry is often demonstrated by adhering to high standards and certifications specific to steel production. Compliance with international quality standards, such as ISO 9001 or the American Society for Testing and Materials (ASTM), assures customers of a product's performance and consistency. Other certifications may focus on environmental standards, highlighting a company's commitment to sustainable manufacturing practices. Trustworthiness of hot-rolled steel strip suppliers often correlates with their ability to provide consistent quality and reliable logistic solutions. End-users demand materials that not only meet engineering specifications but also are delivered on time and within budget. Building long-term relationships in the supply chain through demonstrated reliability and transparency can lead to repeat business and a strong reputation. In conclusion, the fleje de acero laminado stands as a pillar of strength and utility in the modern manufacturing landscape. Grounded in experience and expertise, backed by authoritativeness and trust, these steel strips continue to support a wide array of industrial applications. The continued evolution of processing technologies and quality standards promises even greater capabilities and applications for this indispensable material in the future.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products