Five Stand Tandem Cold Rolling Mill

Jan . 14, 2025 11:54

Back to list

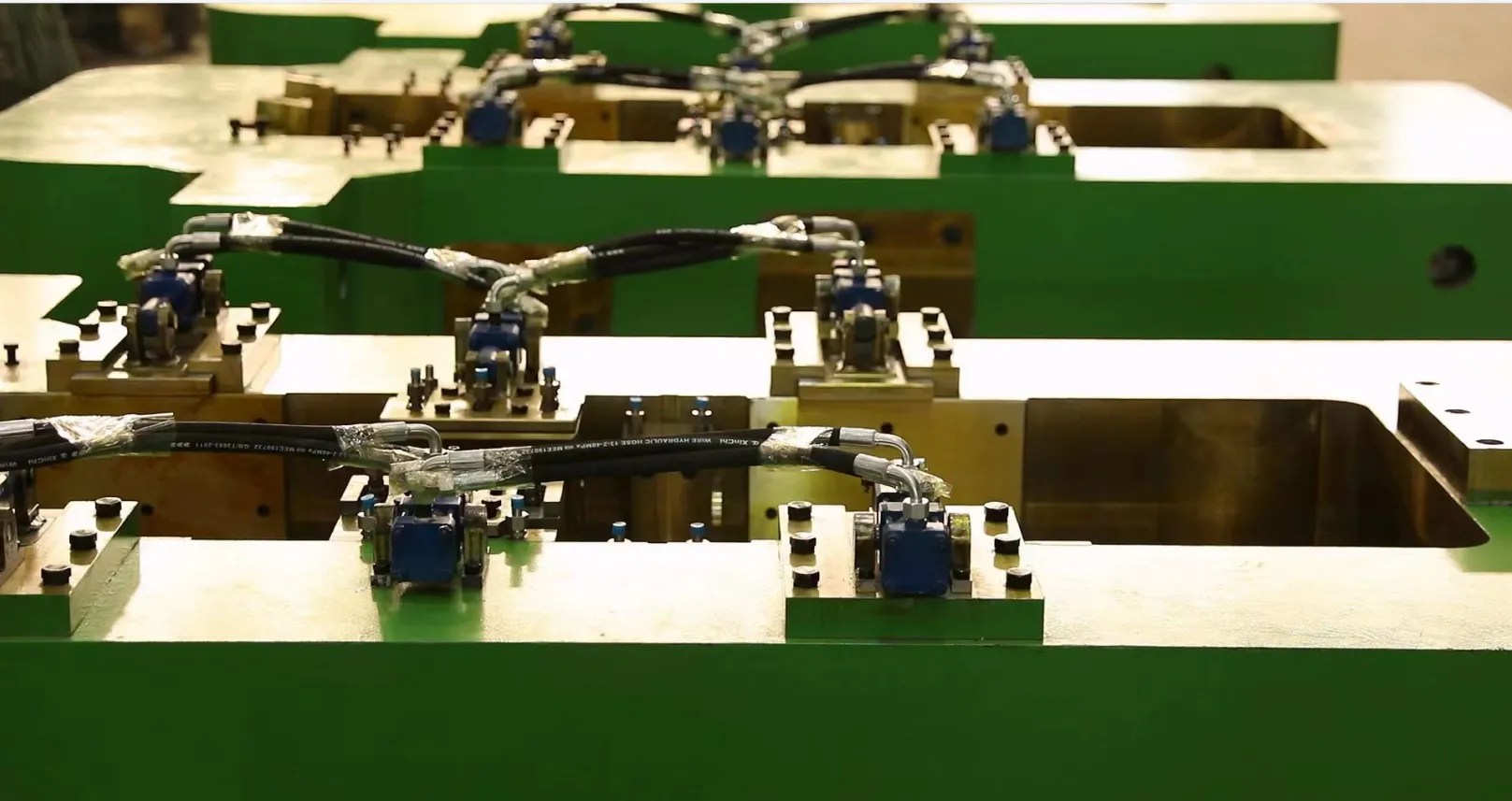

Five Stand Tandem Cold Rolling Mill

Understanding the intricacies of rod and bar mills is essential for businesses seeking to gain a competitive edge in the metal industry. These facilities play a pivotal role in shaping raw metal into the precise products required for various applications, including construction, automotive, and industrial manufacturing.

Moreover, rod and bar mills are sometimes equipped with advanced technologies like thermomechanical treatment systems, which further refines the metal's properties to cater to specialized industrial needs. These added processes highlight an operator's Expertise, allowing them to tailor the product to specific market demands. Investing in state-of-the-art rod and bar mill technology can significantly enhance production efficiency and output quality. However, it is equally important to invest in personnel training and development. Skilled operators with real-world Experience not only enhance operational efficiency but also bring credibility to the operation by maintaining consistency in production output and minimizing waste. In terms of sustainability, modern rod and bar mills are increasingly incorporating environmentally friendly practices. This includes the use of energy-efficient equipment, recycling of materials, and reducing emissions, which not only boosts the facility's public image but also complies with global sustainability standards. In conclusion, the success of a rod and bar mill's operations depends on a harmonious blend of technology and human skill, underscoring the importance of Experience, Expertise, Authoritativeness, and Trustworthiness. By focusing on these principles, companies can not only meet but exceed industry expectations, leading to long-term business growth and an enhanced market reputation.

Moreover, rod and bar mills are sometimes equipped with advanced technologies like thermomechanical treatment systems, which further refines the metal's properties to cater to specialized industrial needs. These added processes highlight an operator's Expertise, allowing them to tailor the product to specific market demands. Investing in state-of-the-art rod and bar mill technology can significantly enhance production efficiency and output quality. However, it is equally important to invest in personnel training and development. Skilled operators with real-world Experience not only enhance operational efficiency but also bring credibility to the operation by maintaining consistency in production output and minimizing waste. In terms of sustainability, modern rod and bar mills are increasingly incorporating environmentally friendly practices. This includes the use of energy-efficient equipment, recycling of materials, and reducing emissions, which not only boosts the facility's public image but also complies with global sustainability standards. In conclusion, the success of a rod and bar mill's operations depends on a harmonious blend of technology and human skill, underscoring the importance of Experience, Expertise, Authoritativeness, and Trustworthiness. By focusing on these principles, companies can not only meet but exceed industry expectations, leading to long-term business growth and an enhanced market reputation.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products