block rolling mill

Jan . 14, 2025 09:58

Back to list

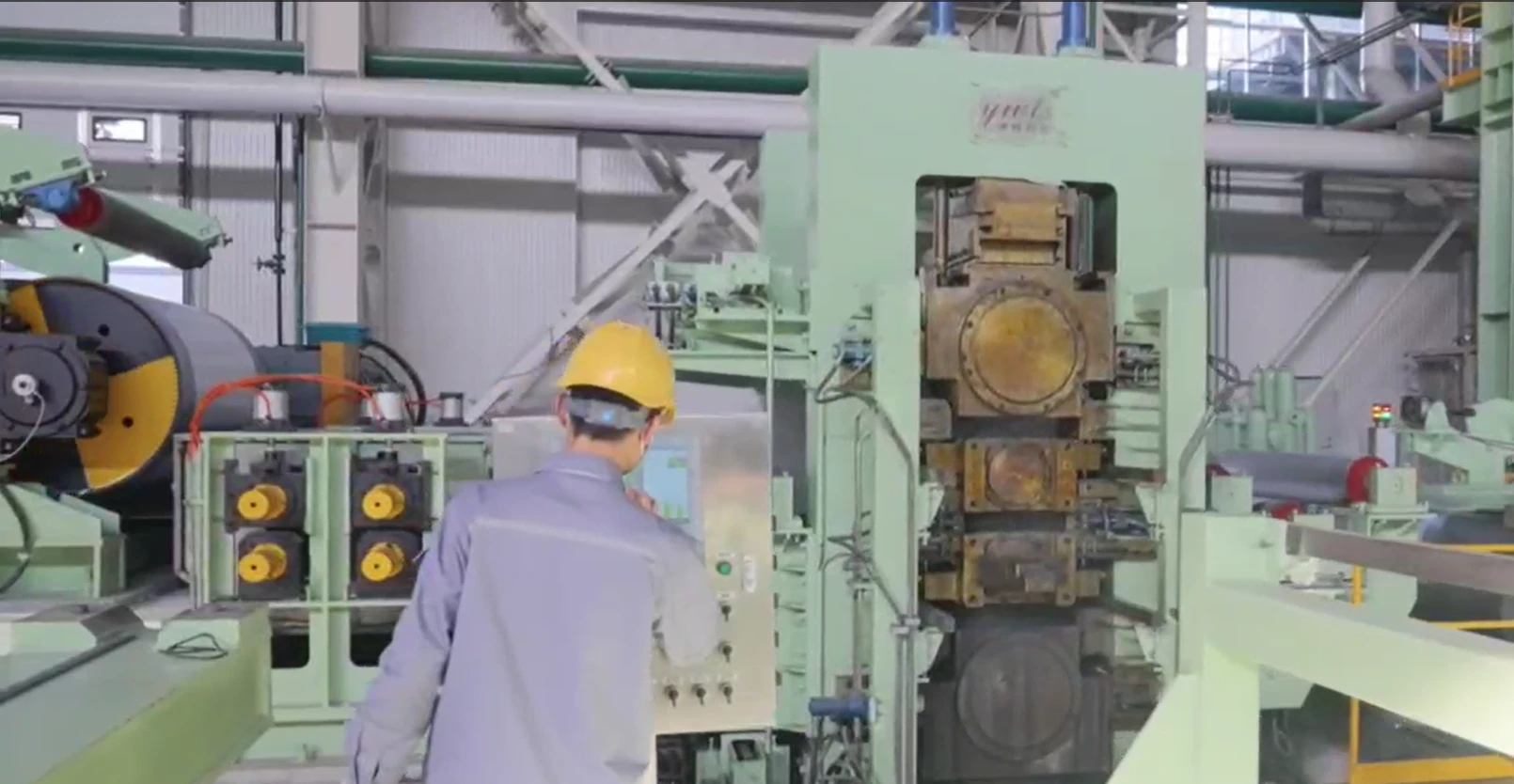

block rolling mill

In the bustling world of metallurgy and heavy machinery, the block rolling mill stands as an indispensable component in the process of transforming raw materials into finely crafted metal products. Unlike traditional rolling mills, block rolling mills are specifically designed to handle the initial stages of metal formation, where large metal slabs are converted into intermediate goods that set the stage for further refinement. This machine’s role is crucial, resting at the heart of industrial operations, underlining the necessity for industries to have a robust understanding and application of this formidable asset.

In an industry where authoritativeness commands respect, aligning with a manufacturer recognized for innovation and quality in block rolling mill production is paramount. Manufacturers at the pinnacle of industry standards offer not only superior products but also comprehensive service packages that include installation, routine maintenance, and immediate troubleshooting. These manufacturers often drive technological advancements, offering enhancements like reduced energy consumption and more precise control over rolling parameters, which feed directly into cost-efficiency and improved product quality. Trustworthiness, the final pillar, is established through transparency and consistent performance. Partnering with manufacturers who provide ample case studies, customer testimonials, and verifiable performance metrics can significantly raise your company's standing in the competitive market. Such assurances reinforce your operations, creating a bedrock of trust among stakeholders and clients. In conclusion, a block rolling mill isn't just a piece of industrial equipment; it is a pivotal investment in your manufacturing cadence. By concentrating on EEAT principles, companies not only enhance their technical prowess but also affirm their market position as leaders in quality and innovation. Whether you are expanding capacity or refining processes, the strategic implementation of a block rolling mill can transform the raw potential of metal into tangible industrial achievements.

In an industry where authoritativeness commands respect, aligning with a manufacturer recognized for innovation and quality in block rolling mill production is paramount. Manufacturers at the pinnacle of industry standards offer not only superior products but also comprehensive service packages that include installation, routine maintenance, and immediate troubleshooting. These manufacturers often drive technological advancements, offering enhancements like reduced energy consumption and more precise control over rolling parameters, which feed directly into cost-efficiency and improved product quality. Trustworthiness, the final pillar, is established through transparency and consistent performance. Partnering with manufacturers who provide ample case studies, customer testimonials, and verifiable performance metrics can significantly raise your company's standing in the competitive market. Such assurances reinforce your operations, creating a bedrock of trust among stakeholders and clients. In conclusion, a block rolling mill isn't just a piece of industrial equipment; it is a pivotal investment in your manufacturing cadence. By concentrating on EEAT principles, companies not only enhance their technical prowess but also affirm their market position as leaders in quality and innovation. Whether you are expanding capacity or refining processes, the strategic implementation of a block rolling mill can transform the raw potential of metal into tangible industrial achievements.

Next:

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products