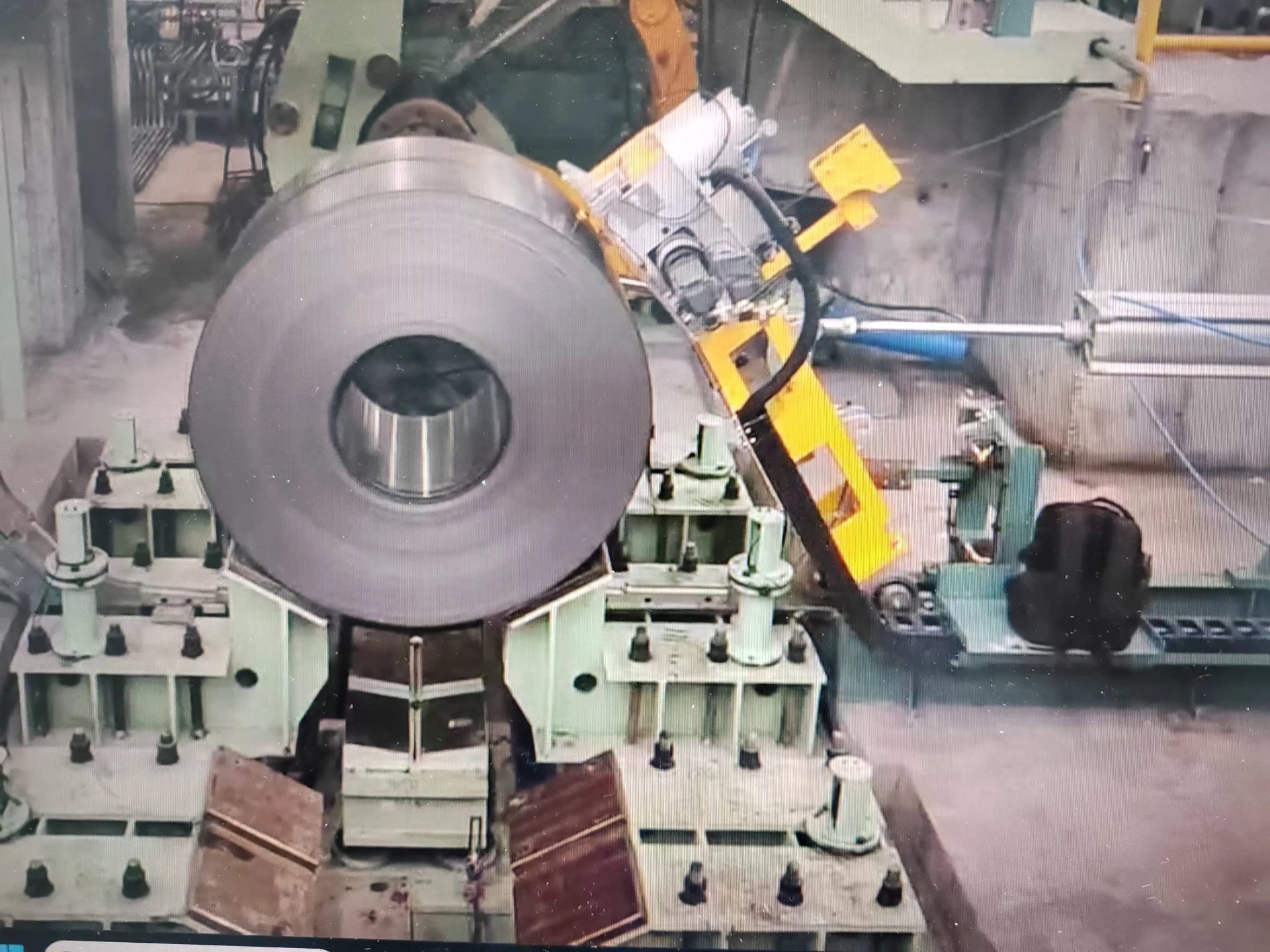

automatic gauge control cold rolling mill

Jan . 13, 2025 17:25

Back to list

automatic gauge control cold rolling mill

Aluminium rolling mills, an integral part of the metalworking industry, serve as the backbone for the production of a variety of aluminium products used across global industries. As a seasoned expert in this domain, I aim to provide an insightful exploration of aluminium rolling mills' operations, highlighting their significance and the advanced technology driving this industry.

The reliability of aluminium rolling mills hinges on their adherence to ethical sourcing and environmental considerations. Reputable mills prioritize eco-friendly operations, often implementing recycling processes that reduce waste and maximize resource efficiency. This commitment to sustainability exemplifies the trustworthiness of aluminium manufacturers who recognize the importance of minimizing their environmental footprint. As the global demand for aluminium continues to rise, the importance of maintaining authoritative operations within rolling mills becomes even more critical. These mills play a vital role in the economy, supporting supply chains worldwide, and their ability to maintain a balance between innovation, quality, and sustainability is what establishes their authority in the market. Investing in state-of-the-art machinery and an expert workforce enables aluminium rolling mills to meet the challenges of modern industrial demands. Their refined processes and commitment to sustainability not only enhance product quality but also ensure environmental responsibility. In a world that increasingly values sustainable industry practices, aluminium rolling mills stand as a testament to progress and innovation within the manufacturing sector.

The reliability of aluminium rolling mills hinges on their adherence to ethical sourcing and environmental considerations. Reputable mills prioritize eco-friendly operations, often implementing recycling processes that reduce waste and maximize resource efficiency. This commitment to sustainability exemplifies the trustworthiness of aluminium manufacturers who recognize the importance of minimizing their environmental footprint. As the global demand for aluminium continues to rise, the importance of maintaining authoritative operations within rolling mills becomes even more critical. These mills play a vital role in the economy, supporting supply chains worldwide, and their ability to maintain a balance between innovation, quality, and sustainability is what establishes their authority in the market. Investing in state-of-the-art machinery and an expert workforce enables aluminium rolling mills to meet the challenges of modern industrial demands. Their refined processes and commitment to sustainability not only enhance product quality but also ensure environmental responsibility. In a world that increasingly values sustainable industry practices, aluminium rolling mills stand as a testament to progress and innovation within the manufacturing sector.

Next:

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products