automatic gauge control cold rolling mill

Jan . 13, 2025 12:34

Back to list

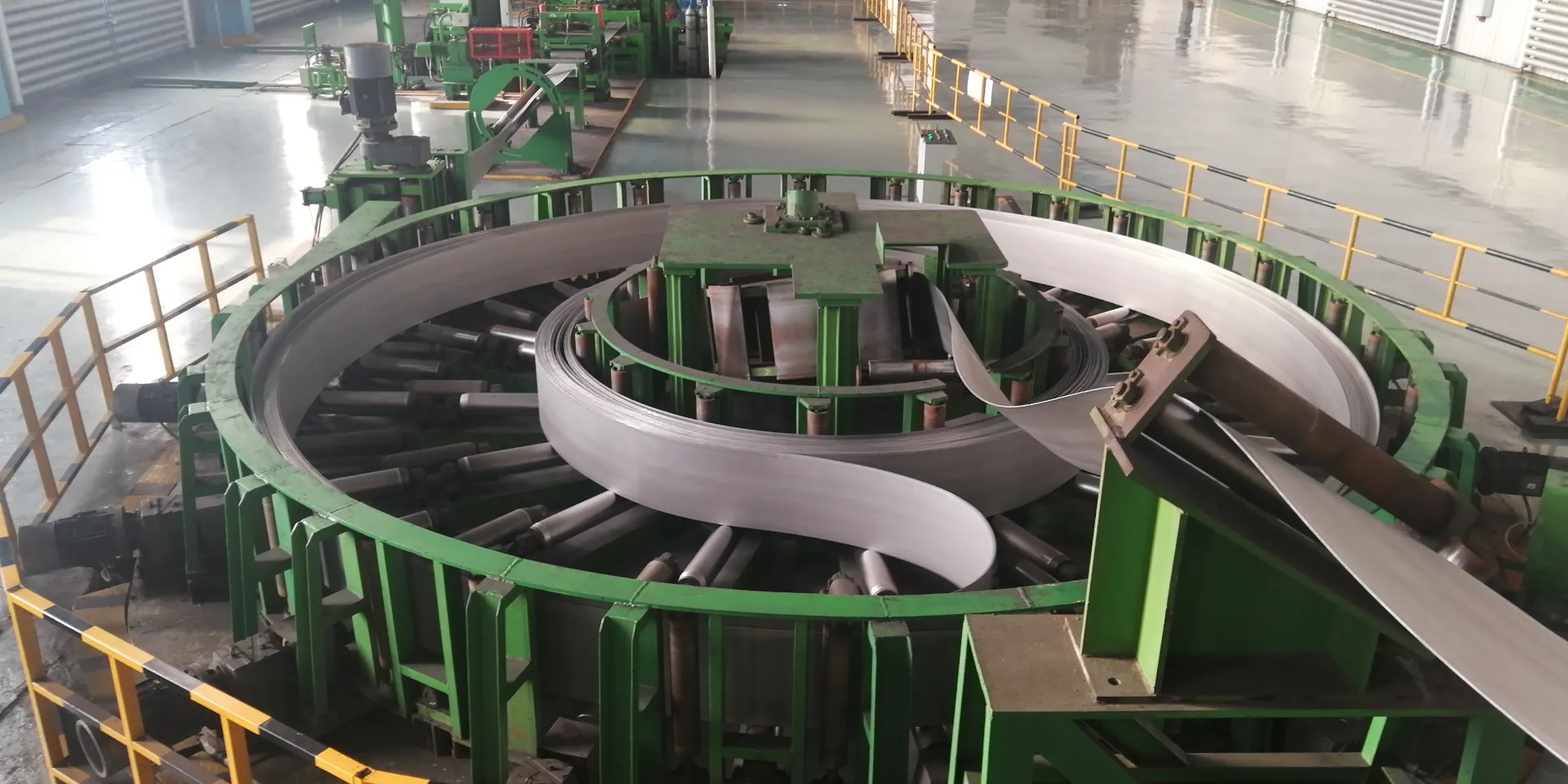

automatic gauge control cold rolling mill

High-quality rolling mill plates are essential components in the metal processing industry, serving as the backbone for a wide range of applications from construction to automotive manufacturing. Known for their durability and versatility, these plates are critical to achieving precision and efficiency in production processes. Leveraging years of industry experience and deep technical knowledge, it's important to explore what makes rolling mill plates stand out, and how they contribute to various sectors.

Authoritativeness in the production of rolling mill plates is reinforced by adherence to international quality standards and certifications. Manufacturers committed to excellence undergo rigorous testing and quality control measures to achieve ISO certifications and other industry accolades. These distinctions not only demonstrate a commitment to producing top-tier products but also assure customers of the product’s legitimacy and reliability. Suppliers with a strong reputation are often preferred partners in large-scale projects, offering peace of mind that the rolling mill plates will perform as expected. Trustworthiness ties the value proposition of rolling mill plates together, underscored by stellar customer testimonials and long-standing industry relationships. Companies that consistently deliver reliable products cultivate trust within their client base, leading to repeat business and word-of-mouth referrals. Customer success stories often highlight the plates’ exceptional performance, confirming their suitability for various applications. Whether it’s for infrastructure development or high-precision tooling, clients rely heavily on the proven track record of rolling mill plate suppliers to deliver results that align with their business objectives. In having these four components—experience, expertise, authoritativeness, and trustworthiness—manufacturers of rolling mill plates stand out in a competitive market. Their products not only meet the evolving needs of different industries but also set benchmarks in quality and performance. As the demand for high-performance metal components continues to grow, the choice of rolling mill plates becomes a critical factor influencing the success of industrial projects worldwide.

Authoritativeness in the production of rolling mill plates is reinforced by adherence to international quality standards and certifications. Manufacturers committed to excellence undergo rigorous testing and quality control measures to achieve ISO certifications and other industry accolades. These distinctions not only demonstrate a commitment to producing top-tier products but also assure customers of the product’s legitimacy and reliability. Suppliers with a strong reputation are often preferred partners in large-scale projects, offering peace of mind that the rolling mill plates will perform as expected. Trustworthiness ties the value proposition of rolling mill plates together, underscored by stellar customer testimonials and long-standing industry relationships. Companies that consistently deliver reliable products cultivate trust within their client base, leading to repeat business and word-of-mouth referrals. Customer success stories often highlight the plates’ exceptional performance, confirming their suitability for various applications. Whether it’s for infrastructure development or high-precision tooling, clients rely heavily on the proven track record of rolling mill plate suppliers to deliver results that align with their business objectives. In having these four components—experience, expertise, authoritativeness, and trustworthiness—manufacturers of rolling mill plates stand out in a competitive market. Their products not only meet the evolving needs of different industries but also set benchmarks in quality and performance. As the demand for high-performance metal components continues to grow, the choice of rolling mill plates becomes a critical factor influencing the success of industrial projects worldwide.

Next:

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products