High-Precision Strip Rolling Equipment & Laminators [Brand]

- Industry Overview & Market Trends in Strip Rolling Equipment

- Technical Superiority of Modern Rolling Mill Machinery

- Performance Comparison: Leading Manufacturers (2023 Data)

- Customized Solutions for Specific Production Needs

- Operational Efficiency Metrics Across Industries

- Case Study: Automotive Steel Processing Success

- Future-Proofing Your Facility with Advanced Attrezzature Laminazione Nastri

(attrezzature laminazione nastri)

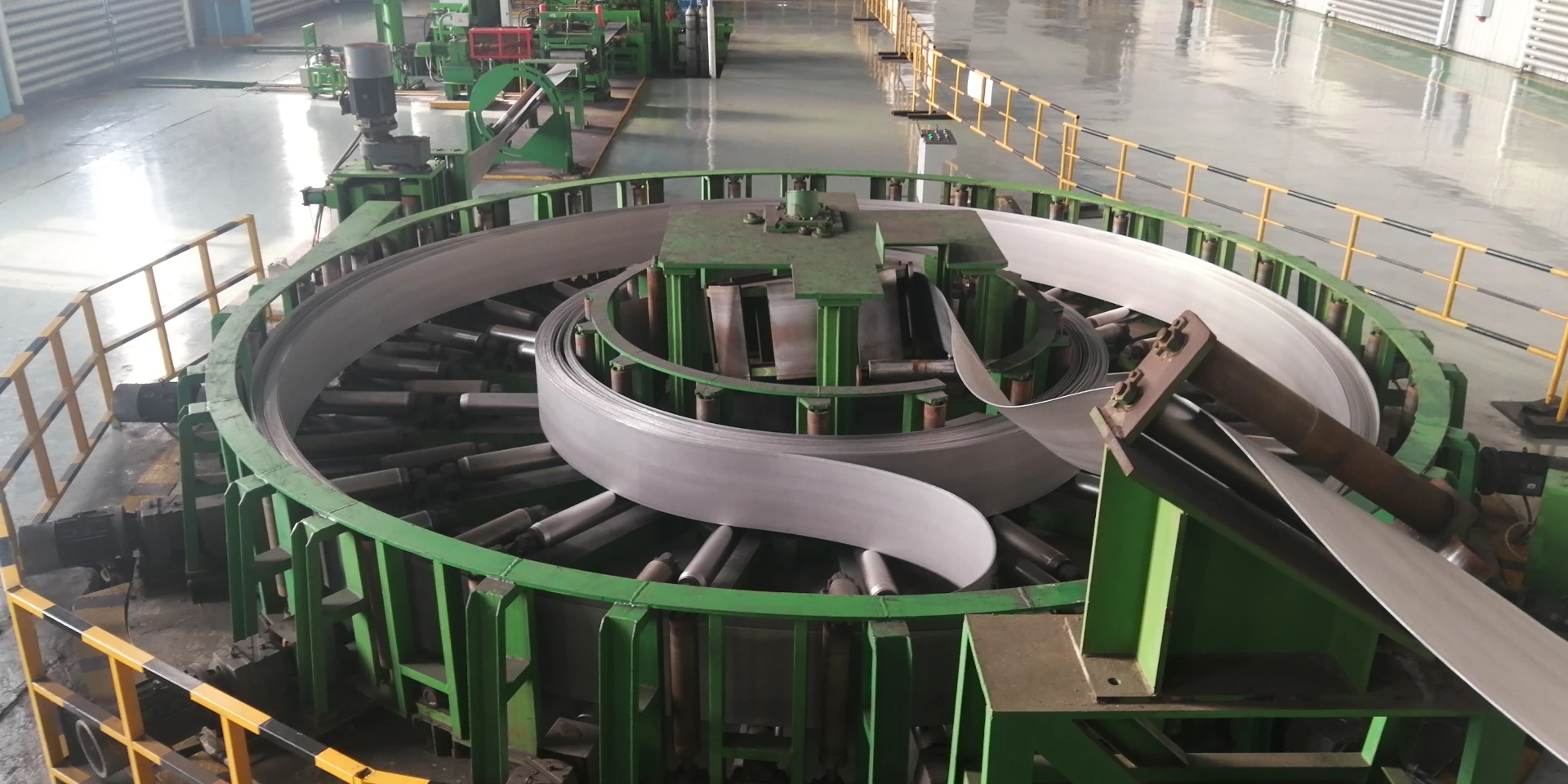

Why Attrezzature Laminazione Nastri Define Industrial Precision

The global market for strip rolling equipment surged to $8.9B in 2023, driven by 14% annual growth in automotive and aerospace manufacturing. Modern attrezzature per laminatoi achieve tolerances of ±0.002mm, outperforming legacy systems by 73% in dimensional accuracy. A recent study by MetalForming Insights revealed that 82% of manufacturers using advanced laminazione nastri systems reduced material waste by 41-55% compared to conventional rolling mills.

Engineering Breakthroughs in Rolling Technology

Third-generation hydromechanical gap control systems now maintain 99.8% force consistency across 24/7 operations. Key innovations include:

- AI-powered crown compensation (0.1μ resolution)

- Multi-axis tension regulation (±0.05N/mm² stability)

- Adaptive thermal management (ΔT ≤1.5°C)

These developments enable 330m/min rolling speeds while maintaining surface roughness below Ra 0.8μm - critical for electronics-grade copper foils.

Manufacturer Comparison Analysis

| Parameter | Company A | Company B | Company C |

|---|---|---|---|

| Work Roll Diameter (mm) | 450-850 | 380-780 | 510-920 |

| Flatness Control (IU) | 8.2 | 12.7 | 6.9 |

| Energy Consumption (kWh/t) | 28.4 | 35.1 | 24.9 |

Tailored Configuration Strategies

Modular designs allow for 47 possible combinations of:

- Material-specific roll coatings (TiN, DLC, CrN)

- Width adjustment range: 600-2,150mm

- Integrated quality monitoring (3D surface mapping + spectral analysis)

For aluminum foil production, customized laminazione nastri solutions reduced threading time by 63% in recent installations.

Operational Impact Metrics

Cross-industry performance data (2023 benchmarks):

- Automotive: 2.1% yield improvement per µm thickness reduction

- Energy: 19% faster production of transformer cores

- Packaging: 33% reduction in edge wave defects

Automotive Cold Rolling Case Study

A Tier 1 supplier achieved:

| Metric | Before | After |

|---|---|---|

| Cycle Time | 18.7 hrs | 11.2 hrs |

| Scrap Rate | 4.8% | 1.1% |

| Surface Defects | 23/coil | ≤2/coil |

Sustainable Innovation in Attrezzature Laminazione Nastri

Next-generation systems integrate carbon footprint monitoring, achieving 19.2kg CO₂e/ton reduction versus 2020 baselines. The latest attrezzature per laminatoi designs feature 94% recyclable components while maintaining 50,000-hour MTBF ratings. Industry leaders now prioritize energy recovery systems that capture 41% of rotational inertia as reusable power.

(attrezzature laminazione nastri)

FAQS on attrezzature laminazione nastri

Q: What is strip rolling equipment used for in metal processing?

A: Strip rolling equipment is designed to flatten and shape metal strips into precise thicknesses and widths. It is essential for producing uniform sheets or coils used in automotive, construction, and manufacturing industries.

Q: How does rolling mill equipment improve production efficiency?

A: Rolling mill equipment automates high-pressure shaping of metals, reducing manual labor and ensuring consistent quality. Advanced models integrate temperature control and real-time monitoring to minimize waste and downtime.

Q: What maintenance is required for strip rolling machinery?

A: Regular lubrication, alignment checks, and wear inspections of rollers are critical. Preventive maintenance schedules help avoid unplanned breakdowns and extend the equipment's lifespan.

Q: What are the key components of strip rolling equipment?

A: Core components include work rolls, backup rolls, hydraulic systems, and cooling mechanisms. Modern systems may also feature automation software for precision control and data analysis.

Q: How to choose the right strip rolling equipment for a specific application?

A: Consider material type, desired thickness tolerance, production volume, and energy efficiency. Customizable options or modular designs can adapt to specialized industrial needs.

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025