Agc System For Hot/Cold Strip Rolling Mill

Jan . 14, 2025 11:04

Back to list

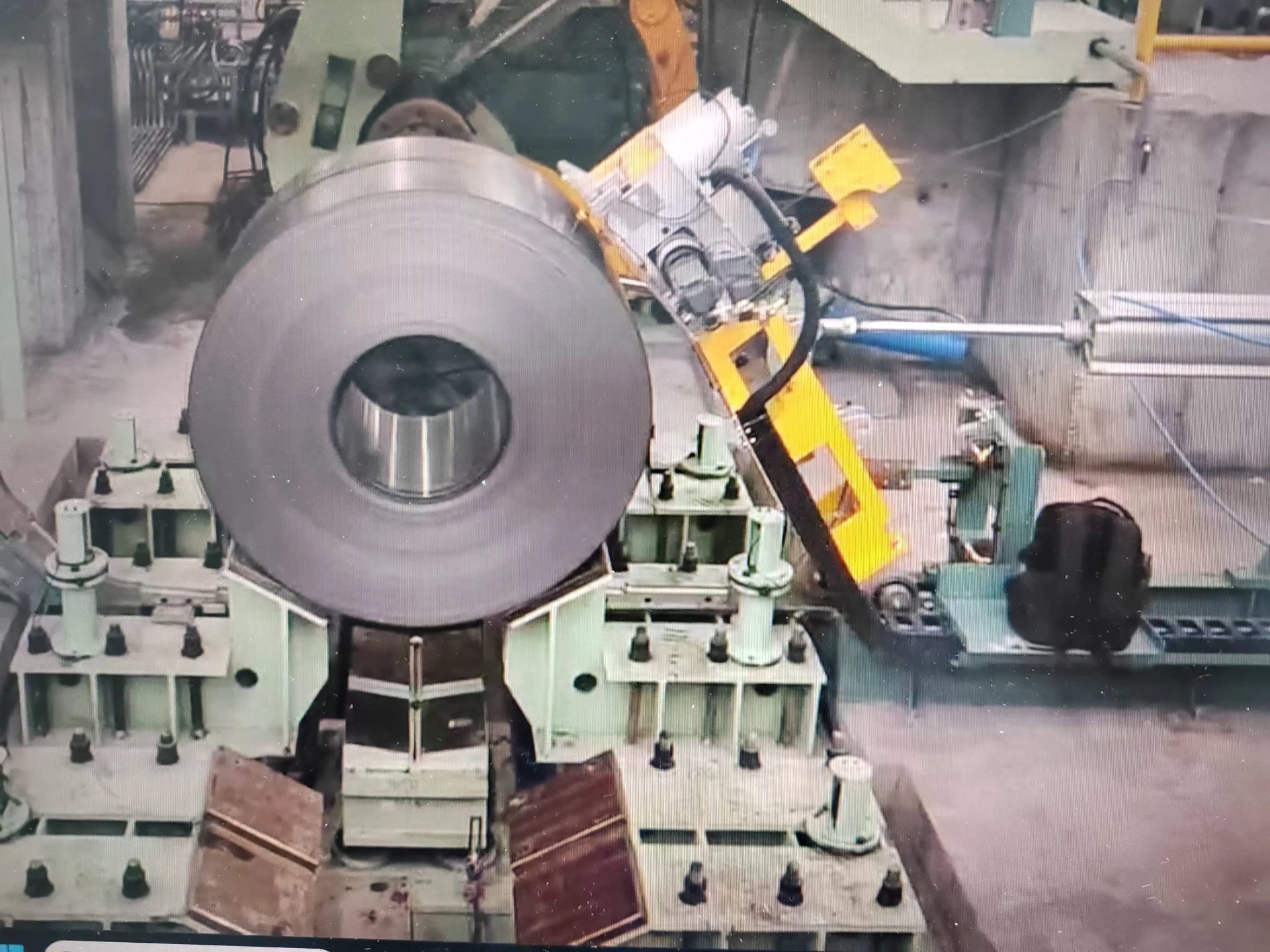

Agc System For Hot/Cold Strip Rolling Mill

Enhancing efficiency in metalworking processes, the motorized rolling mill stands out as a vital piece of equipment for industries ranging from jewelry crafting to large-scale metal production. While the traditional rolling mill has served artisans and manufacturers for decades, the motorized variant offers innovative advancements that meet the demands of modern production environments.

Authority in manufacture and integration into workflow processes comes from leading brands that have pioneered advancements in this technology. Companies with a longstanding history in metallurgical equipment production present motorized rolling mills that come with certifications and endorsements from industry experts. These endorsements often come after rigorous testing and quality checks, which reassures users of the equipment's integrity and performance. Trustworthiness in this category of equipment is further supported by the network of after-sales service. Established manufacturers offer comprehensive customer support, ranging from installation guidance to regular maintenance services. These services ensure the equipment operates at optimal performance levels, thereby extending its lifespan and providing users with a secure investment. Motorized rolling mills have transformed metal processing industries, aligning with the continuous push towards automation and precision. The integration of trusted expertise, authoritative recommendations, and authentic user experiences creates a strong foundation for choosing these machines. As technology progresses, the role of the motorized rolling mill will likely expand, continually pushing the boundaries of what's possible in metalworking. For any entity aiming for growth and efficiency, investing in a motorized rolling mill not only bolsters production capabilities but positions the business at the forefront of industry innovation.

Authority in manufacture and integration into workflow processes comes from leading brands that have pioneered advancements in this technology. Companies with a longstanding history in metallurgical equipment production present motorized rolling mills that come with certifications and endorsements from industry experts. These endorsements often come after rigorous testing and quality checks, which reassures users of the equipment's integrity and performance. Trustworthiness in this category of equipment is further supported by the network of after-sales service. Established manufacturers offer comprehensive customer support, ranging from installation guidance to regular maintenance services. These services ensure the equipment operates at optimal performance levels, thereby extending its lifespan and providing users with a secure investment. Motorized rolling mills have transformed metal processing industries, aligning with the continuous push towards automation and precision. The integration of trusted expertise, authoritative recommendations, and authentic user experiences creates a strong foundation for choosing these machines. As technology progresses, the role of the motorized rolling mill will likely expand, continually pushing the boundaries of what's possible in metalworking. For any entity aiming for growth and efficiency, investing in a motorized rolling mill not only bolsters production capabilities but positions the business at the forefront of industry innovation.

Latest news

-

Adjusting Roll Gap in 6Hi Reversing Cold Rolling Mill for Thin StripNewsNov.13,2025

-

Quality Control Standards for Automatic Gauge Control in Strip RollingNewsNov.13,2025

-

Effect of Skin Pass Rolling on Metal DuctilityNewsNov.13,2025

-

Key Components of a Modern TempermillNewsNov.13,2025

-

Common Wear Patterns of Work Roll in Tandem Cold Mill OperationsNewsNov.13,2025

-

Applications of GTV Laser Cladding in Oil and Gas IndustryNewsNov.13,2025

-

Revolutionary Skin Pass Rolling Technology for Enhanced Steel QualityNewsNov.04,2025

Related Products