Temper Mill

Jan . 26, 2025 02:24

Back to list

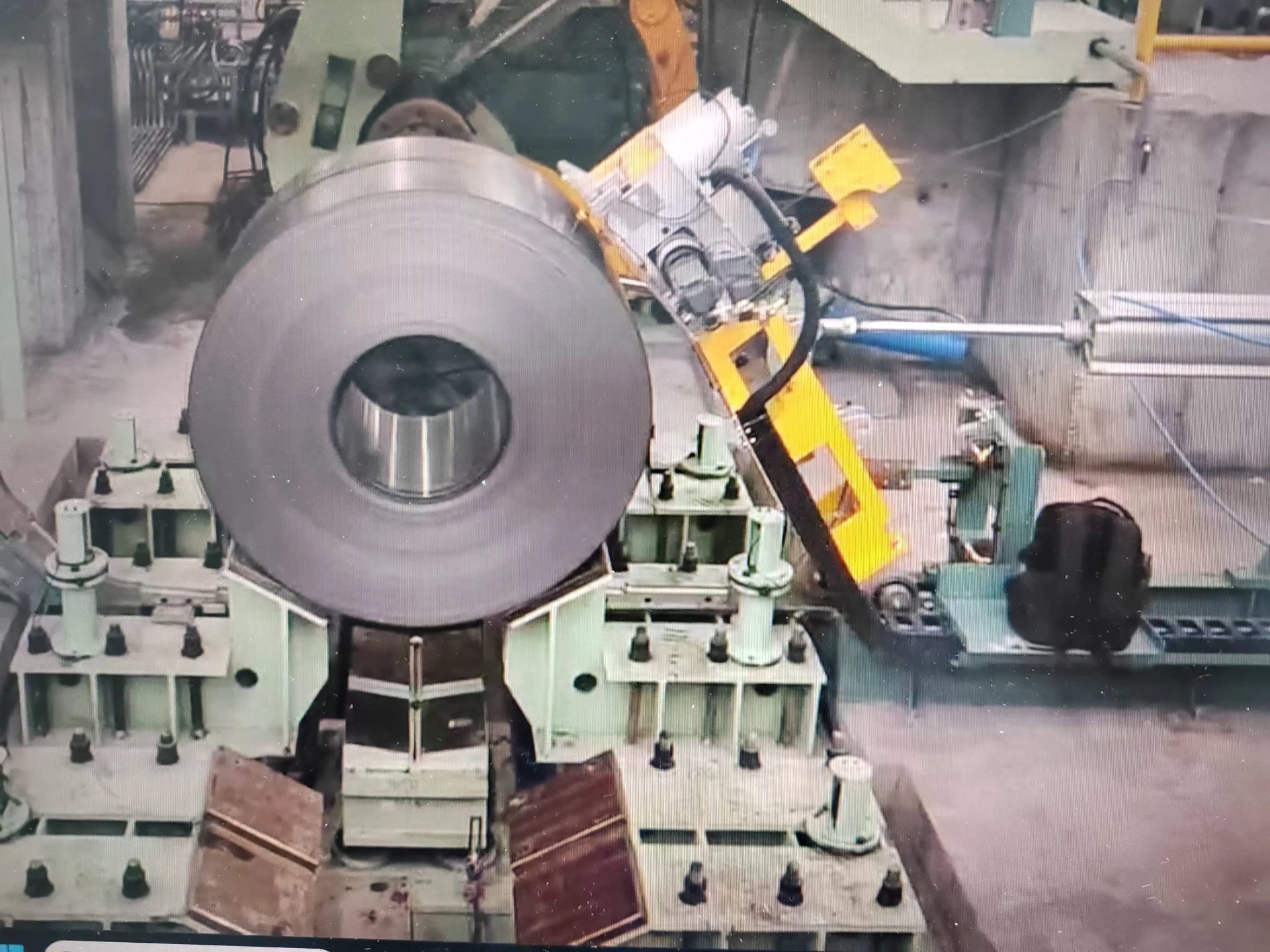

Temper Mill

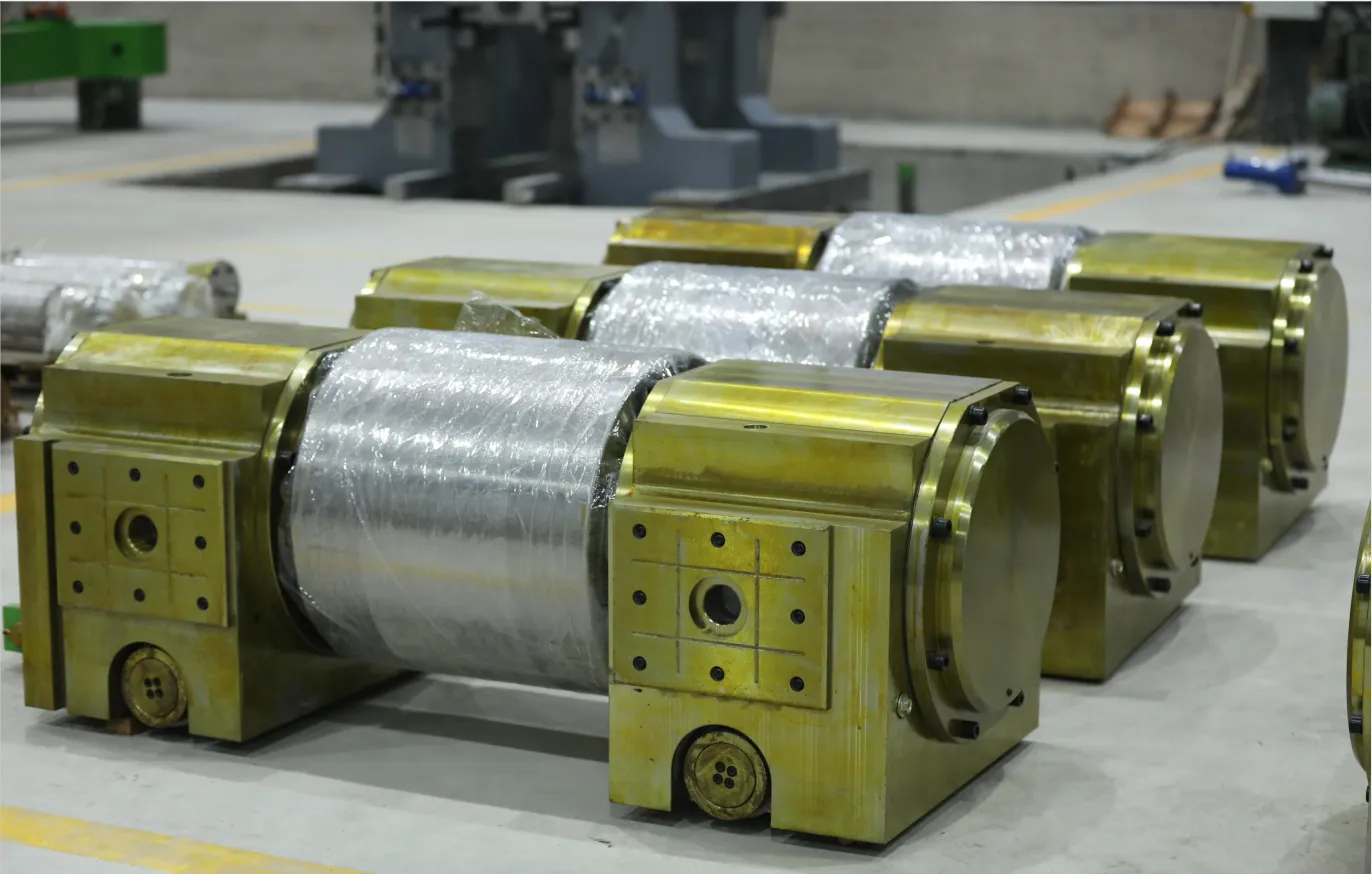

Integrating a rolling machine, often referred to as a unified rolling mill in the steel manufacturing industry, is a pivotal advancement that continues to reshape the dynamics of metallurgical processes. These machines are vital in the production realm, finely crafting metal sheets, plates, and coils with unmatched precision and efficiency, ensuring superior product quality across various industrial applications.

The authoritativeness of integrated rolling machines is underscored by endorsements from leading industry experts and organizations. Several studies presented in metallurgical conferences highlight their efficiency in reducing production costs while maintaining high output quality. The ability to handle a diverse range of metals and alloys while ensuring minimal material wastage is frequently cited in research articles as one of the significant advantages of these machines. Leading manufacturers, like Primetals Technologies and Danieli, have been at the forefront in integrating AI and machine learning to further enhance the predictive maintenance and operational efficiencies of these rolling machines. Building trustworthiness in the realm of integrated rolling machines involves rigorous testing and quality assurance processes recognized globally. Companies that deploy these machines invest in comprehensive training and certification programs for their operators, emphasizing best practices in machine handling and maintenance. Additionally, the incorporation of eco-friendly practices in the design and operation of these machines, aimed at reducing energy consumption and emissions, enhances their appeal to environmentally conscious businesses and consumers. In conclusion, the integrated rolling machine stands as a cornerstone for modern metallurgical processes, offering a blend of precision, efficiency, and adaptability. Its ability to meet high industry standards while fostering innovations in metal product manufacturing firmly positions it as an indispensable tool for contemporary needs. Through advanced engineering, authoritative endorsements, and reliable performance feedback, this piece of machinery not only meets but exceeds the stringent demands of today's industrial landscape, paving the way for future advancements in metal processing technologies.

The authoritativeness of integrated rolling machines is underscored by endorsements from leading industry experts and organizations. Several studies presented in metallurgical conferences highlight their efficiency in reducing production costs while maintaining high output quality. The ability to handle a diverse range of metals and alloys while ensuring minimal material wastage is frequently cited in research articles as one of the significant advantages of these machines. Leading manufacturers, like Primetals Technologies and Danieli, have been at the forefront in integrating AI and machine learning to further enhance the predictive maintenance and operational efficiencies of these rolling machines. Building trustworthiness in the realm of integrated rolling machines involves rigorous testing and quality assurance processes recognized globally. Companies that deploy these machines invest in comprehensive training and certification programs for their operators, emphasizing best practices in machine handling and maintenance. Additionally, the incorporation of eco-friendly practices in the design and operation of these machines, aimed at reducing energy consumption and emissions, enhances their appeal to environmentally conscious businesses and consumers. In conclusion, the integrated rolling machine stands as a cornerstone for modern metallurgical processes, offering a blend of precision, efficiency, and adaptability. Its ability to meet high industry standards while fostering innovations in metal product manufacturing firmly positions it as an indispensable tool for contemporary needs. Through advanced engineering, authoritative endorsements, and reliable performance feedback, this piece of machinery not only meets but exceeds the stringent demands of today's industrial landscape, paving the way for future advancements in metal processing technologies.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products