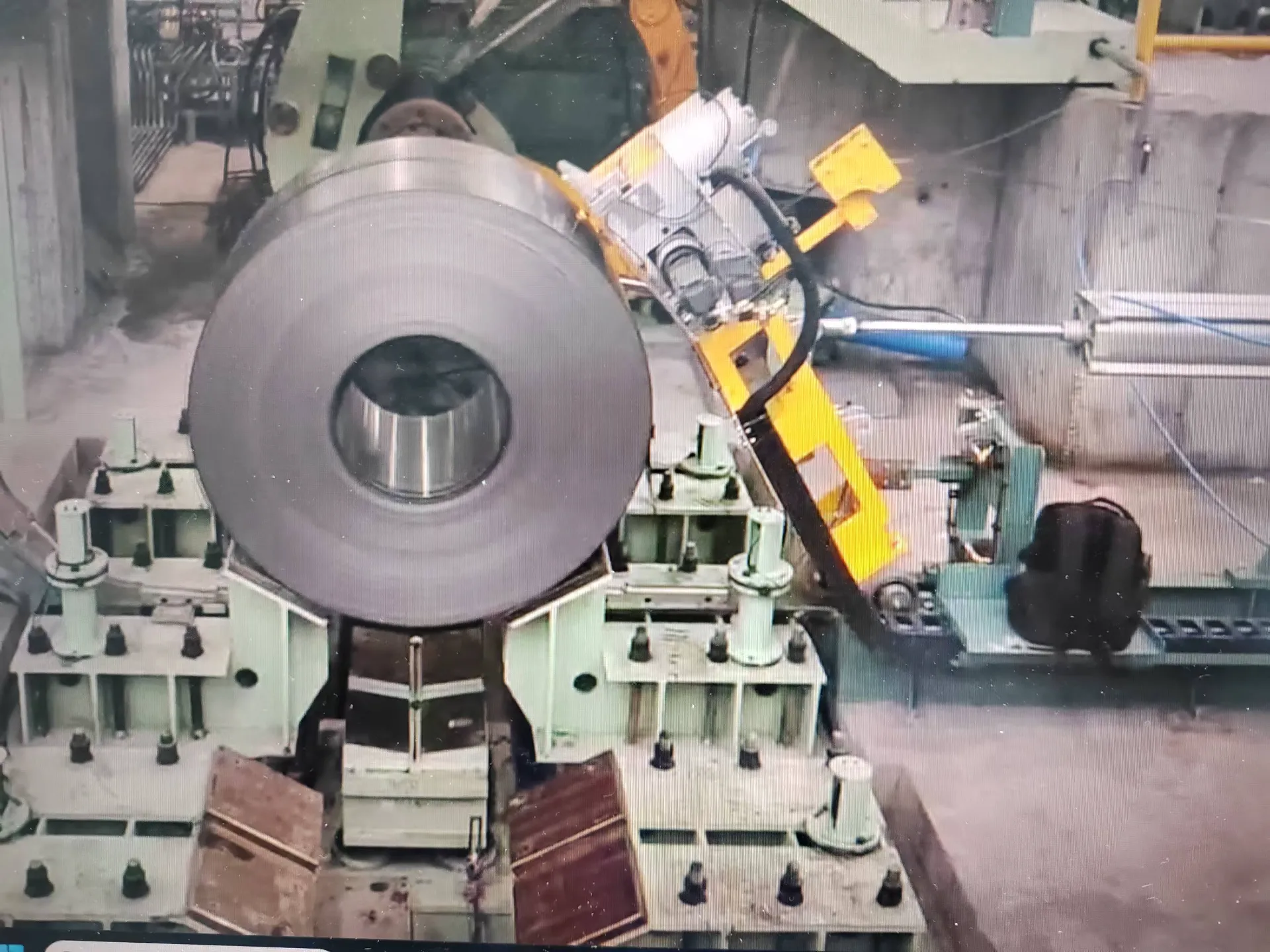

cold rolling mill

Jan . 24, 2025 03:57

Back to list

cold rolling mill

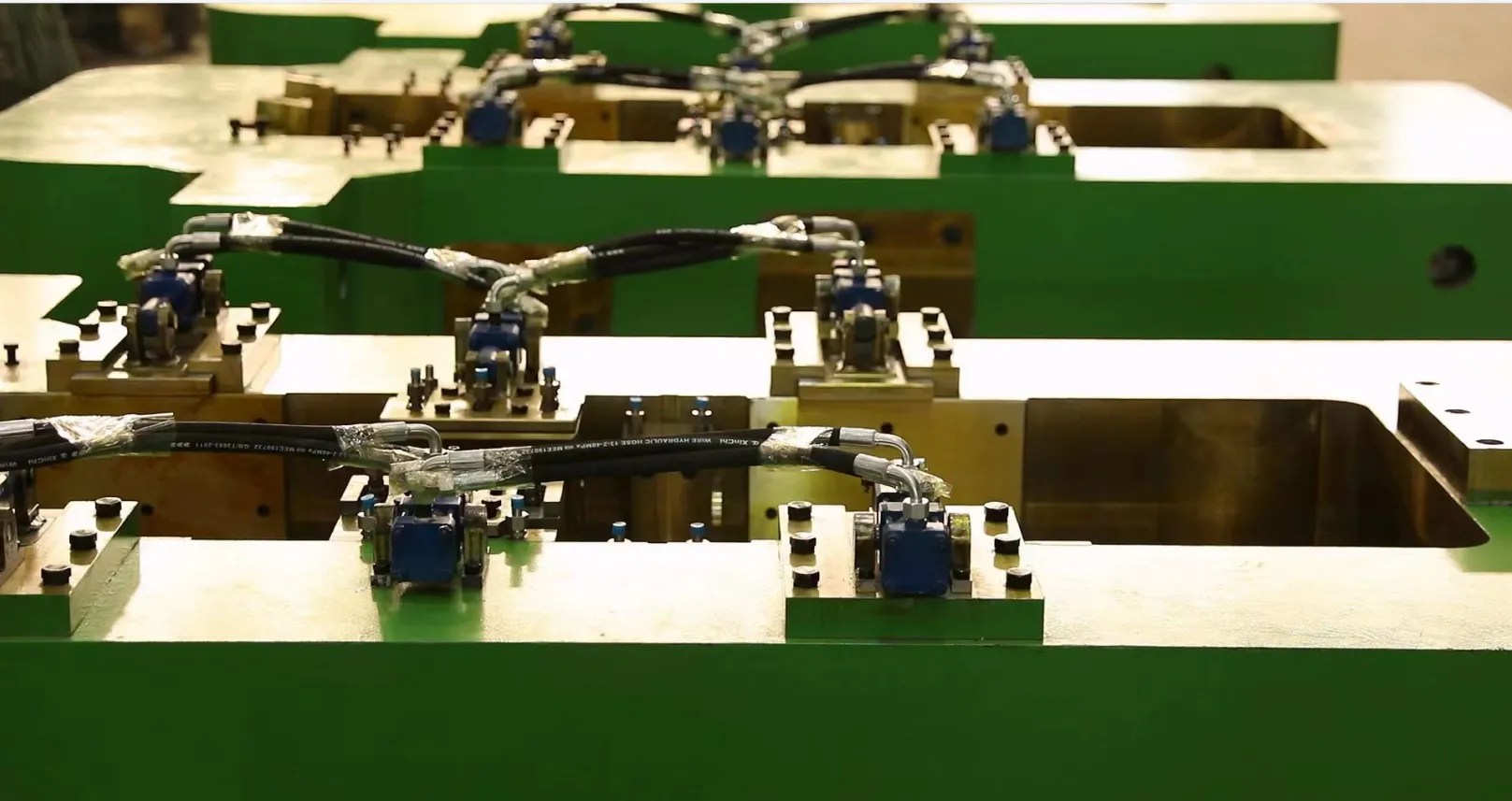

In the ever-evolving landscape of industrial machinery, the rolling mill stand has become a cornerstone of metal processing. With decades of innovation behind it, the rolling mill stand is engineered to meet the modern demands of efficiency, precision, and sustainability.

Almost as vital as skillful operation is the issue of trustworthiness in selecting rolling mill stands. Businesses must allocate resources to partner with reputable manufacturers backed by a proven track record of reliability and innovation. Case studies showcasing the lifespan, maintenance ease, and adaptability of these machines across various industrial applications serve as testimonials to their dependability. New trends in the sector emphasize the importance of customization. Tailored stands that cater to specific production needs—be it small-batch manufacturing or full-scale industrial deployment—add a strategic advantage. Through customizing roll configurations and automation solutions, businesses can optimize productivity and meet bespoke demands. Investing in rolling mill stands extends beyond the acquisition cost. It encompasses a commitment to quality control, employee training, and technological upgrades. The machines serve not just as equipment but as pivotal elements of a company's operational infrastructure. Their performance directly translates into the quality of the final product, making them a critical factor in the value chain. Ultimately, the world of rolling mill stands is a dynamic interplay of engineering prowess and material science. For industries seeking precision and reliability in metal processing, these machines represent the pinnacle of what modern engineering and innovation can achieve. Ensuring their optimal functionality while adapting to technological advancements can substantially impact a company’s operational success and industrial prestige.

Almost as vital as skillful operation is the issue of trustworthiness in selecting rolling mill stands. Businesses must allocate resources to partner with reputable manufacturers backed by a proven track record of reliability and innovation. Case studies showcasing the lifespan, maintenance ease, and adaptability of these machines across various industrial applications serve as testimonials to their dependability. New trends in the sector emphasize the importance of customization. Tailored stands that cater to specific production needs—be it small-batch manufacturing or full-scale industrial deployment—add a strategic advantage. Through customizing roll configurations and automation solutions, businesses can optimize productivity and meet bespoke demands. Investing in rolling mill stands extends beyond the acquisition cost. It encompasses a commitment to quality control, employee training, and technological upgrades. The machines serve not just as equipment but as pivotal elements of a company's operational infrastructure. Their performance directly translates into the quality of the final product, making them a critical factor in the value chain. Ultimately, the world of rolling mill stands is a dynamic interplay of engineering prowess and material science. For industries seeking precision and reliability in metal processing, these machines represent the pinnacle of what modern engineering and innovation can achieve. Ensuring their optimal functionality while adapting to technological advancements can substantially impact a company’s operational success and industrial prestige.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products