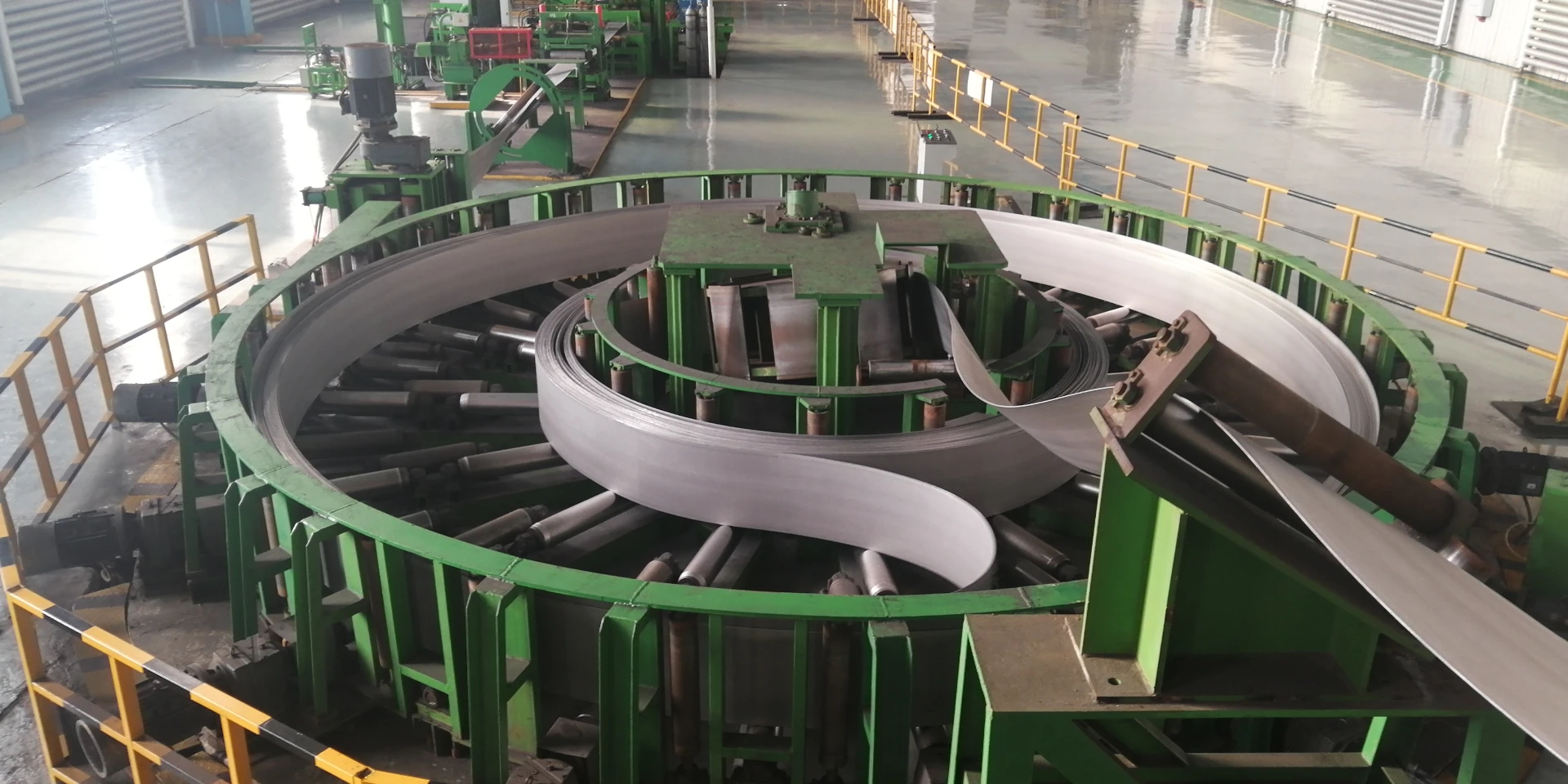

Temper Mill

Jan . 21, 2025 05:00

Back to list

Temper Mill

Cold-rolled steel strip is a remarkable product that boasts both versatility and strength, making it a crucial component in numerous industries. This product, integral to the manufacturing sector, is characterized by its distinctive manufacturing process, which imparts unique properties that benefit a wide range of applications. This article explores the key features, applications, and benefits of cold-rolled steel strip while drawing on industry expertise and practical experience.

In addition to these technical benefits, cold-rolled steel strip offers significant cost advantages. The material's strength and durability can reduce wear and replacement costs, which is a crucial consideration for budget-conscious industries. Furthermore, the efficient manufacturing process can result in lower energy consumption compared to other methods, providing both economic and environmental benefits. Expertise in the field underscores the importance of selecting the appropriate grade and specification of cold-rolled steel strip for particular applications. Different alloys and heat treatments can tailor the material's properties to meet specific needs, whether it be enhanced ductility, impact resistance, or another requirement. Professionals in the field can provide valuable insights into these choices, ensuring that the material selected provides the best possible performance for its intended use. Trust in the quality and provenance of cold-rolled steel strip is enhanced by adherence to international standards and certifications. Reputable manufacturers often comply with ISO standards, ensuring that their products meet stringent quality and performance criteria. For buyers, these certifications serve as a mark of reliability, providing confidence in the material's ability to meet demanding operational conditions. Innovations in manufacturing technology and materials science continue to drive advancements in cold-rolled steel strip production. As sustainability becomes a more prominent concern, manufacturers are developing techniques to reduce the environmental impact of production processes, resulting in more eco-friendly steel products. These innovations further enhance the appeal of cold-rolled steel strip as a forward-looking choice for modern industries. In conclusion, cold-rolled steel strip stands out as a high-performance, versatile material, prized for its superior mechanical properties, excellent surface quality, and precision. Its adaptability to a wide range of applications, from automotive to precision machinery, highlights its indispensable role in contemporary manufacturing. By leveraging industry expertise and technological advancements, cold-rolled steel strip continues to meet and exceed the evolving demands of modern industrial applications.

In addition to these technical benefits, cold-rolled steel strip offers significant cost advantages. The material's strength and durability can reduce wear and replacement costs, which is a crucial consideration for budget-conscious industries. Furthermore, the efficient manufacturing process can result in lower energy consumption compared to other methods, providing both economic and environmental benefits. Expertise in the field underscores the importance of selecting the appropriate grade and specification of cold-rolled steel strip for particular applications. Different alloys and heat treatments can tailor the material's properties to meet specific needs, whether it be enhanced ductility, impact resistance, or another requirement. Professionals in the field can provide valuable insights into these choices, ensuring that the material selected provides the best possible performance for its intended use. Trust in the quality and provenance of cold-rolled steel strip is enhanced by adherence to international standards and certifications. Reputable manufacturers often comply with ISO standards, ensuring that their products meet stringent quality and performance criteria. For buyers, these certifications serve as a mark of reliability, providing confidence in the material's ability to meet demanding operational conditions. Innovations in manufacturing technology and materials science continue to drive advancements in cold-rolled steel strip production. As sustainability becomes a more prominent concern, manufacturers are developing techniques to reduce the environmental impact of production processes, resulting in more eco-friendly steel products. These innovations further enhance the appeal of cold-rolled steel strip as a forward-looking choice for modern industries. In conclusion, cold-rolled steel strip stands out as a high-performance, versatile material, prized for its superior mechanical properties, excellent surface quality, and precision. Its adaptability to a wide range of applications, from automotive to precision machinery, highlights its indispensable role in contemporary manufacturing. By leveraging industry expertise and technological advancements, cold-rolled steel strip continues to meet and exceed the evolving demands of modern industrial applications.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products