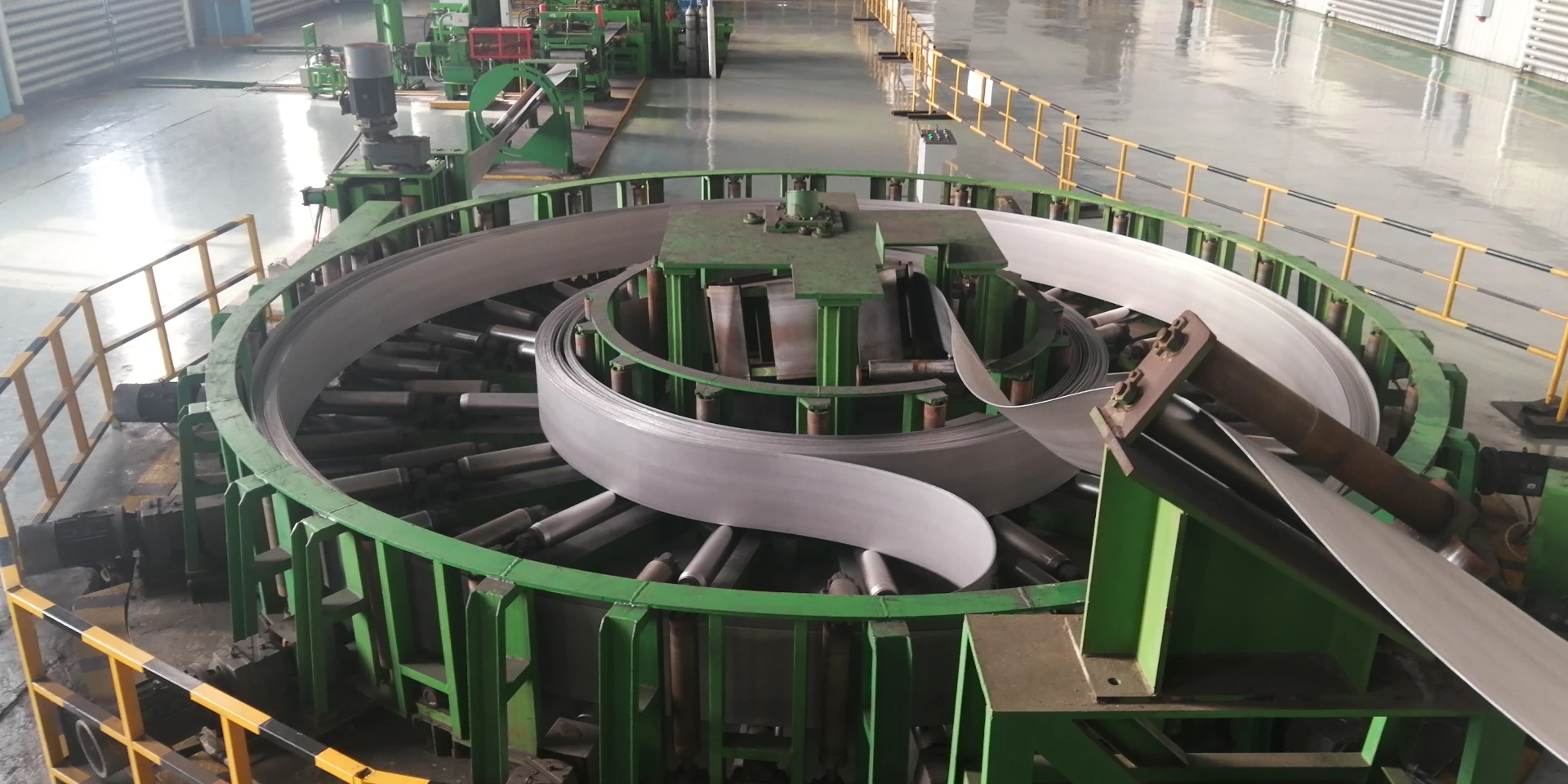

Skin Pass Mill

Jan . 20, 2025 13:40

Back to list

Skin Pass Mill

In the world of metal manufacturing, the rolling mill stands as a vital component in producing top-quality metal products. The precision, efficiency, and advancements in technology surrounding modern rolling mills are remarkable, and their significance cannot be overstated.

Trustworthiness in the realm of rolling mills is built on a foundation of reliability and consistency. Trusted manufacturers have a long history of supporting large-scale industrial operations, from infrastructure projects to automotive and aerospace applications. Their machines are designed to withstand rigorous working environments, providing uninterrupted service that companies worldwide depend on. User feedback often highlights the durability and precision of these rolling mills, which translates to lower maintenance needs and higher productivity. Furthermore, the market is witnessing a noticeable trend towards automation. Automated rolling mills are revolutionizing the production landscape – their ability to operate with minimal human intervention drastically reduces errors and increases efficiency. These systems allow operators to focus on managing the production process as a whole, rather than individual stages, offering a more cohesive approach to metal manufacturing. For businesses exploring investment in rolling mills, understanding these elements and recognizing reputable manufacturers is crucial. A due diligence process that evaluates a mill's technological prowess, its compatibility with existing infrastructure, and the manufacturer's reputation is essential. Businesses often achieve this by conducting comprehensive market research, attending industry exhibitions, and consulting with experts who have a deep understanding of the material properties and production processes. Ultimately, the role of a metallic rolling mill extends far beyond its basic function of shaping metal. It embodies a commitment to precision, innovation, and sustainability. As industries evolve, the need for advanced rolling mills continues to grow, underscoring their significance in achieving cutting-edge production standards. Businesses that prioritize these machines' experience, expertise, authoritativeness, and trustworthiness often find themselves at the forefront of their respective fields, driving forward with confidence and competence.

Trustworthiness in the realm of rolling mills is built on a foundation of reliability and consistency. Trusted manufacturers have a long history of supporting large-scale industrial operations, from infrastructure projects to automotive and aerospace applications. Their machines are designed to withstand rigorous working environments, providing uninterrupted service that companies worldwide depend on. User feedback often highlights the durability and precision of these rolling mills, which translates to lower maintenance needs and higher productivity. Furthermore, the market is witnessing a noticeable trend towards automation. Automated rolling mills are revolutionizing the production landscape – their ability to operate with minimal human intervention drastically reduces errors and increases efficiency. These systems allow operators to focus on managing the production process as a whole, rather than individual stages, offering a more cohesive approach to metal manufacturing. For businesses exploring investment in rolling mills, understanding these elements and recognizing reputable manufacturers is crucial. A due diligence process that evaluates a mill's technological prowess, its compatibility with existing infrastructure, and the manufacturer's reputation is essential. Businesses often achieve this by conducting comprehensive market research, attending industry exhibitions, and consulting with experts who have a deep understanding of the material properties and production processes. Ultimately, the role of a metallic rolling mill extends far beyond its basic function of shaping metal. It embodies a commitment to precision, innovation, and sustainability. As industries evolve, the need for advanced rolling mills continues to grow, underscoring their significance in achieving cutting-edge production standards. Businesses that prioritize these machines' experience, expertise, authoritativeness, and trustworthiness often find themselves at the forefront of their respective fields, driving forward with confidence and competence.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products