650 temper mill

Mar . 05, 2025 02:53

Back to list

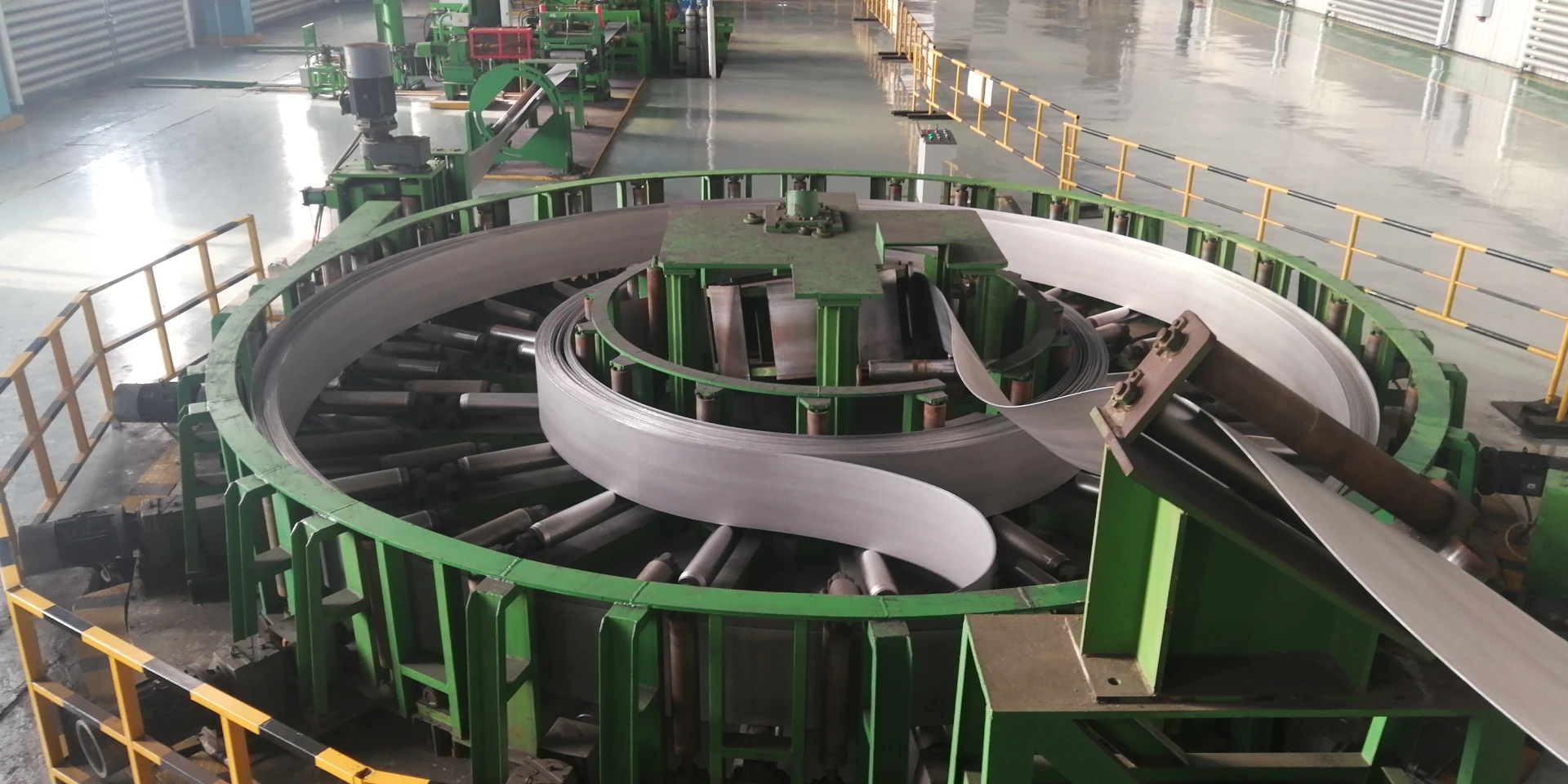

650 temper mill

The 650 temper mill represents a cornerstone of modern steel processing, significantly enhancing the properties and quality of steel products. This process, known as tempering, involves the final cold rolling of hot-rolled steel before it undergoes further processing such as cutting, painting, or coating. The 650 temper mill is specifically engineered to improve the flatness and surface finish of steel, crucial elements in the manufacturing industries such as automotive, construction, and appliance manufacturing.

Trustworthiness in the context of a 650 temper mill relates directly to its ability to consistently deliver superior products. High-quality steel produced through temper mills is known to exhibit improved surface cleanliness and reduced levels of residual stress, making it more predictable in subsequent manufacturing processes. This dependability translates into a more streamlined production process, reassuring manufacturers of the material consistency and reliability essential for maintaining their own product standards. Real-world experience with the 650 temper mill emphasizes its transformative impact on steel processing. Manufacturers report significant reductions in defects such as edge wave and flatness inconsistencies, which not only saves on material costs but also enhances the overall aesthetic and functional quality of the end products. The high throughput capability of these mills ensures that manufacturers can meet large-scale production demands without compromising on quality, offering a competitive edge in a marketplace where both precision and speed are paramount. Furthermore, advancements in temper mill technology, such as automation and real-time monitoring systems, have further propelled the capabilities of the 650 temper mill. Operators can now leverage data analytics to optimize mill performance continually, leading to even greater efficiency and precision. The integration of cutting-edge technology means that these mills are evolving to meet the ever-rising standards of the modern manufacturing industry. In conclusion, the 650 temper mill stands as a testament to the intersection of engineering precision and metallurgical excellence. Representing a crucial step in the steel production process, it enhances the material properties and surface quality of steel, meeting the rigorous demands of diverse industrial applications. Through its sophisticated operation and robust reliability, the 650 temper mill not only underscores the evolution of steel processing but also fortifies the foundation upon which modern technological advancements are built. Its trusted performance and consistent results render it an unparalleled asset in the landscape of industrial manufacturing.

Trustworthiness in the context of a 650 temper mill relates directly to its ability to consistently deliver superior products. High-quality steel produced through temper mills is known to exhibit improved surface cleanliness and reduced levels of residual stress, making it more predictable in subsequent manufacturing processes. This dependability translates into a more streamlined production process, reassuring manufacturers of the material consistency and reliability essential for maintaining their own product standards. Real-world experience with the 650 temper mill emphasizes its transformative impact on steel processing. Manufacturers report significant reductions in defects such as edge wave and flatness inconsistencies, which not only saves on material costs but also enhances the overall aesthetic and functional quality of the end products. The high throughput capability of these mills ensures that manufacturers can meet large-scale production demands without compromising on quality, offering a competitive edge in a marketplace where both precision and speed are paramount. Furthermore, advancements in temper mill technology, such as automation and real-time monitoring systems, have further propelled the capabilities of the 650 temper mill. Operators can now leverage data analytics to optimize mill performance continually, leading to even greater efficiency and precision. The integration of cutting-edge technology means that these mills are evolving to meet the ever-rising standards of the modern manufacturing industry. In conclusion, the 650 temper mill stands as a testament to the intersection of engineering precision and metallurgical excellence. Representing a crucial step in the steel production process, it enhances the material properties and surface quality of steel, meeting the rigorous demands of diverse industrial applications. Through its sophisticated operation and robust reliability, the 650 temper mill not only underscores the evolution of steel processing but also fortifies the foundation upon which modern technological advancements are built. Its trusted performance and consistent results render it an unparalleled asset in the landscape of industrial manufacturing.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products