مطحنة تمرير الجلد عالية الجودة 4

Feb . 19, 2025 04:00

Back to list

مطحنة تمرير الجلد عالية الجودة 4

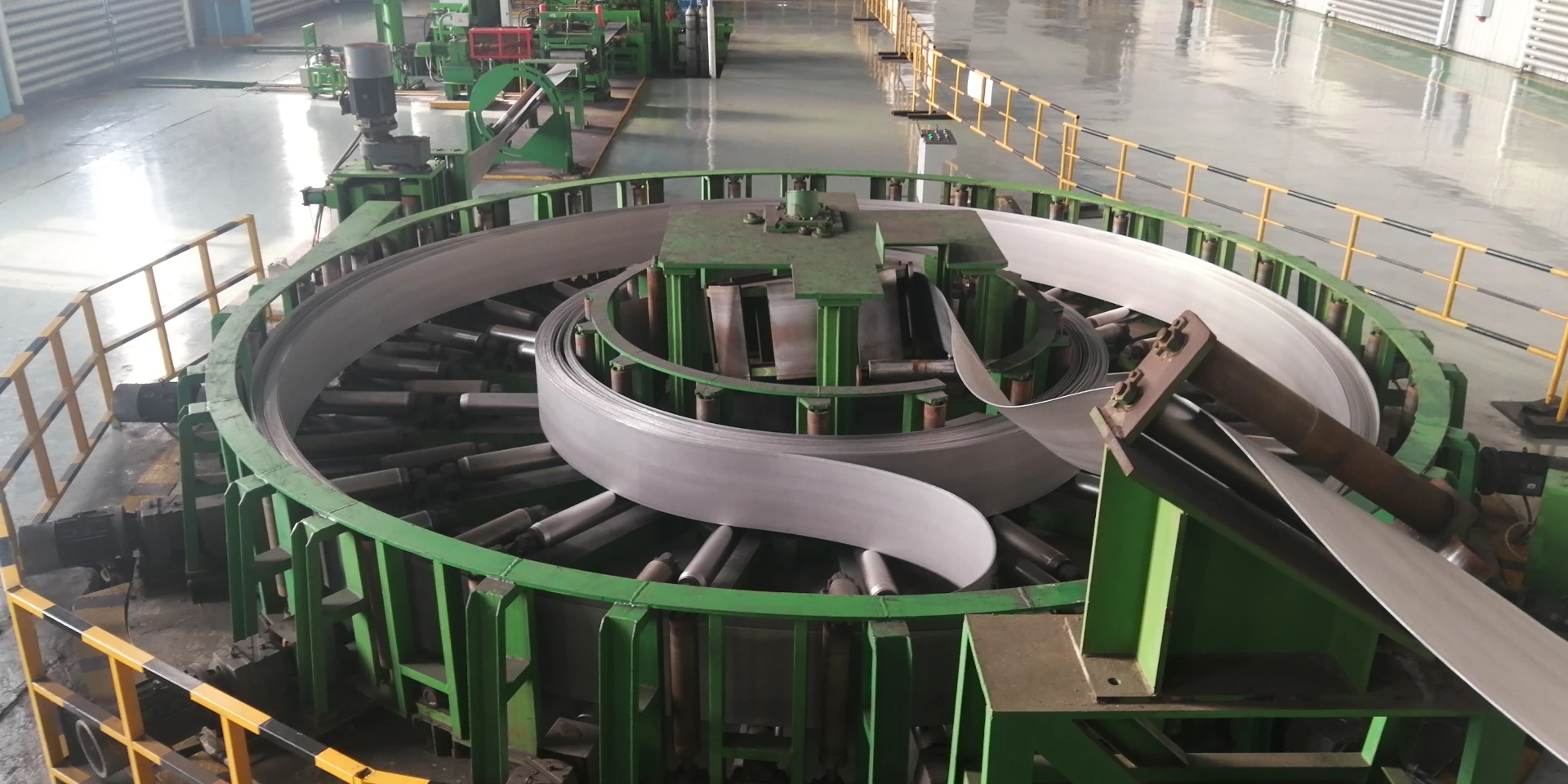

The high-quality 4-high skin pass mill revolutionizes cold-rolling projects by offering state-of-the-art solutions for achieving superior surface finishes and enhanced mechanical properties of metals. This advanced equipment bridges the gap between the initial stages of manufacturing and the final application requirements, delivering results that consistently meet industry demands.

Moreover, the skin pass mill's advanced hydraulic and control systems facilitate precise adjustments to roll pressure and speed, allowing for the customization of finishes based on specific project requirements. Operators can fine-tune settings to achieve desired gloss levels or textures, enhancing the aesthetic appeal of the final product while maintaining durability. Efficiency in operation is another hallmark of high-quality 4-high skin pass mills. These systems are designed to optimize energy consumption and reduce waste, contributing to a more sustainable manufacturing process. The incorporation of automated monitoring systems ensures real-time feedback and adjustments, minimizing downtime and maximizing productivity. Further reinforcing its trustworthiness, manufacturers of these mills often offer comprehensive after-sales support, including maintenance packages and training programs. This commitment ensures that operators remain knowledgeable about the latest practices and technologies, thereby extending the longevity and reliability of their equipment. In conclusion, the 4-high skin pass mill's combination of high performance, precision, and adaptability makes it an indispensable tool in modern metalworking. With its roots deeply embedded in technological innovation and backed by authoritative expertise and experience, it continues to set the standard for excellence in the industry. As such, businesses invested in utilizing high-quality 4-high skin pass mills can confidently expect improved outcomes in product quality, operational efficiency, and overall market competitiveness.

Moreover, the skin pass mill's advanced hydraulic and control systems facilitate precise adjustments to roll pressure and speed, allowing for the customization of finishes based on specific project requirements. Operators can fine-tune settings to achieve desired gloss levels or textures, enhancing the aesthetic appeal of the final product while maintaining durability. Efficiency in operation is another hallmark of high-quality 4-high skin pass mills. These systems are designed to optimize energy consumption and reduce waste, contributing to a more sustainable manufacturing process. The incorporation of automated monitoring systems ensures real-time feedback and adjustments, minimizing downtime and maximizing productivity. Further reinforcing its trustworthiness, manufacturers of these mills often offer comprehensive after-sales support, including maintenance packages and training programs. This commitment ensures that operators remain knowledgeable about the latest practices and technologies, thereby extending the longevity and reliability of their equipment. In conclusion, the 4-high skin pass mill's combination of high performance, precision, and adaptability makes it an indispensable tool in modern metalworking. With its roots deeply embedded in technological innovation and backed by authoritative expertise and experience, it continues to set the standard for excellence in the industry. As such, businesses invested in utilizing high-quality 4-high skin pass mills can confidently expect improved outcomes in product quality, operational efficiency, and overall market competitiveness.

Latest news

-

Indian Clients Visit YWLX to Inspect Skin-pass MillNewsJun.22,2025

-

Typical Products from Reversing Cold Rolling ProcessNewsMay.26,2025

-

Surface Finish Improvement through Skin Pass RollingNewsMay.26,2025

-

Integration of AGC Systems in Modern Cold Rolling MillsNewsMay.26,2025

-

Cold Rolling in the Context of High-Strength Steel DemandNewsMay.26,2025

-

AGC in Hot Rolling Mills: Challenges and SolutionsNewsMay.26,2025

-

Why Reversing Cold Rolling Mills Are Ideal for Specialty MetalsNewsMay.13,2025

Related Products